High-strength, stress-relieved steel and SKD-11/D2 blades with vacuum heat treatment ensure over 3,000 hours’ service life, exceptional hardness, and wear resistance, reducing downtime and costs while handling large volumes reliably.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

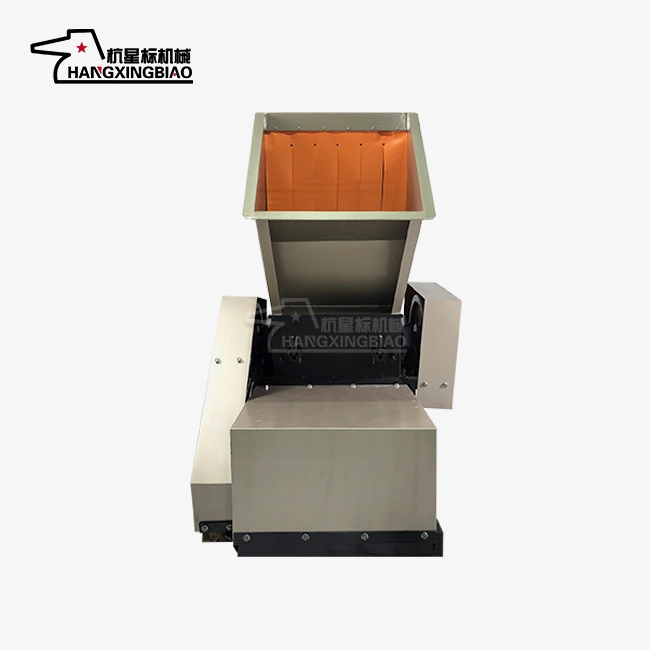

beef bone crusher

Beef Bone Crusher: Professional Bone Processing Solution for Your Business

Are you looking for a reliable beef bone crusher that delivers consistent results? Look no further! Our industrial-grade bone crushing machine transforms tough beef bones into uniform particles, perfect for pet food manufacturing, fertilizer production, and rendering applications. With over 30 years of specialized experience in crushing technology, Hangzhou Xingbiao Machinery delivers the performance and durability you need.

Why Choose Our Industrial Bone Crushing Machine?

Superior Construction and Durability

Advanced Crushing Technology

Our "shear + impact" crushing ensures uniform particle size (>90%) without secondary screening. Anti-winding comb teeth prevent jamming from tissue or cartilage, keeping production running smoothly.

Flexible Output Control

Different applications require different particle sizes. Our screening system offers 2-100mm mesh options. Simply change the screen to achieve your desired output size. Whether you need coarse fragments for rendering or fine particles for pet food, one machine handles all requirements.

The adjustable blade speed gives you additional control over the final product. This flexibility makes the beef bone crusher suitable for various industries and applications.

Energy Efficient Operation

Optimized motor and transmission reduce power use 10–15%, requiring only 8–12 kWh per ton. This boosts efficiency, lowers operating costs, and maintains high productivity for long-term savings.

Complete Model Range for Every Need

Mobile Units

Perfect for smaller operations or multiple processing locations. These compact units feature universal wheels for easy positioning. Capacity ranges from 50-500kg per hour.

Fixed Installation Models

Ideal for dedicated processing lines. These medium-capacity machines integrate seamlessly into your existing workflow. They're built for continuous operation with minimal supervision.

Industrial Scale Systems

High-volume operations benefit from our largest crushers. These powerhouses process 1-10 tons per hour. They can link with conveyors and other equipment for fully automated processing.

Safety and Maintenance Features

Fully enclosed, thick-steel design with anti-rebound baffles and safety shields protects operators. "Open and stop" interlocks cut power during access. Side-access chamber allows quick cleaning, halving maintenance time.

Proven Performance Across Industries

Pet food manufacturers rely on our crushers for consistent bone meal production. The uniform particle size ensures even nutrient distribution in final products. Rendering plants appreciate the high-volume capacity and continuous operation capability.

Fertilizer producers benefit from the controlled output size. The processed bone meal integrates perfectly into organic fertilizer blends. Research facilities value the smaller mobile units for pilot projects and testing.

Expert Support Every Step of the Way

Our 20-engineer development team provides comprehensive application support. We help you select the right model for your specific needs. Installation guidance ensures optimal performance from day one.

You'll receive complete operator training and ongoing technical support. Our 24-hour response guarantee means help is always available when you need it. Regular follow-up visits keep your equipment running at peak efficiency.

Start Processing Beef Bones More Efficiently Today

Ready to upgrade your bone processing operation? Contact our specialists at postmaster@xingbiaocrusher.com for detailed specifications and pricing. We'll help you find the perfect beef bone crusher solution for your production requirements.

Learn about our latest products and discounts through SMS or email