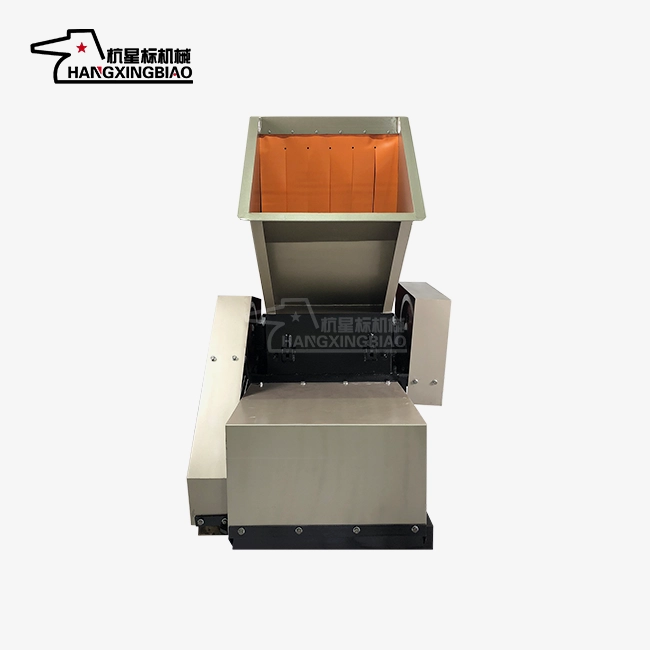

Engineered specifically for soft plastics, the pp crusher solving entanglement issues common with films and bags.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

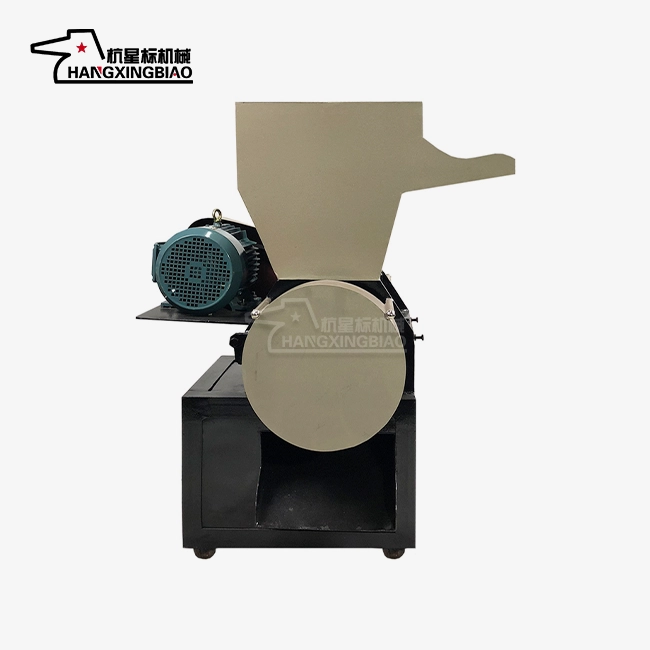

pp crusher

Professional PP Crusher Solutions for Efficient Plastic Processing

Are you looking for a reliable pp crusher to streamline your plastic processing operations? At Hangzhou Xingbiao Machinery Co., Ltd., we specialize in delivering high-performance crushing solutions that transform your plastic waste into valuable recycled materials. Our advanced equipment handles polypropylene and various plastic types with exceptional efficiency, making it perfect for manufacturers seeking cost-effective recycling solutions.

Why Choose Our Plastic Crushing Equipment?

Unmatched Processing Efficiency

Our pulverizing machines provide exceptional execution over different capacity ranges. From small-scale operations handling 50kg per hour to industrial-grade frameworks taking care of up to 2000kg hourly, you'll discover the culminate arrangement for your needs. The gear bolsters 24-hour persistent operation, guaranteeing your generation never stops.

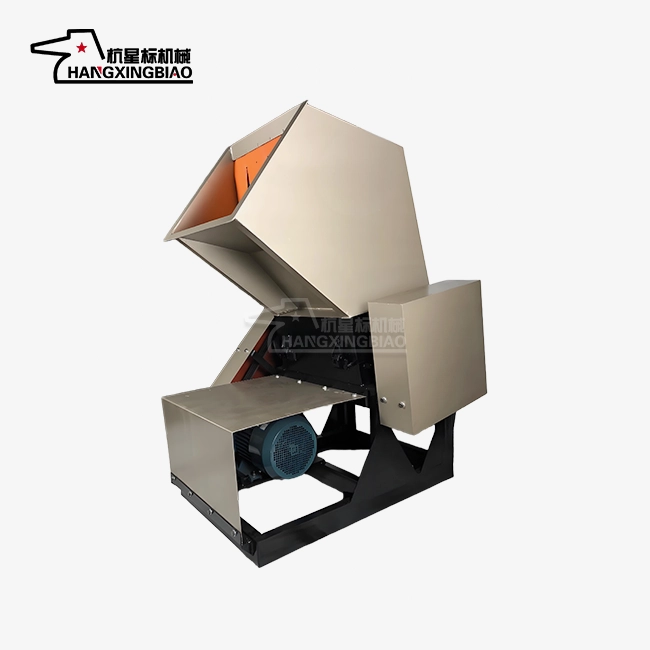

Superior Build Quality and Durability

We construct our machines using high-quality steel plates with stress relief treatment. This ensures no deformation during extended operation periods. The cutting blades feature premium materials like SKD-11 and D2 mold steel, providing exceptional wear resistance and extended service life.

Versatile Material Compatibility

Your pp crusher handles various plastic types effortlessly:

- Soft plastics (PE films, woven bags)

- Hard plastics (ABS, PC components)

- Foam materials (EPS, EVA)

- Irregular shapes (bottles, containers)

Key Features That Set Us Apart

Precise Particle Size Control

You can accomplish correct yield determinations by selecting diverse screen sizes extending from 2mm to 100mm. This adaptability permits you to create materials appropriate for different reusing applications, from coarse parts to fine particles prepared for reprocessing.

Energy-Efficient Operation

Our optimized motor design reduces energy consumption by 10-15% compared to traditional equipment. Processing one ton of plastic requires only 8-12 kilowatt hours, significantly lowering your operational costs.

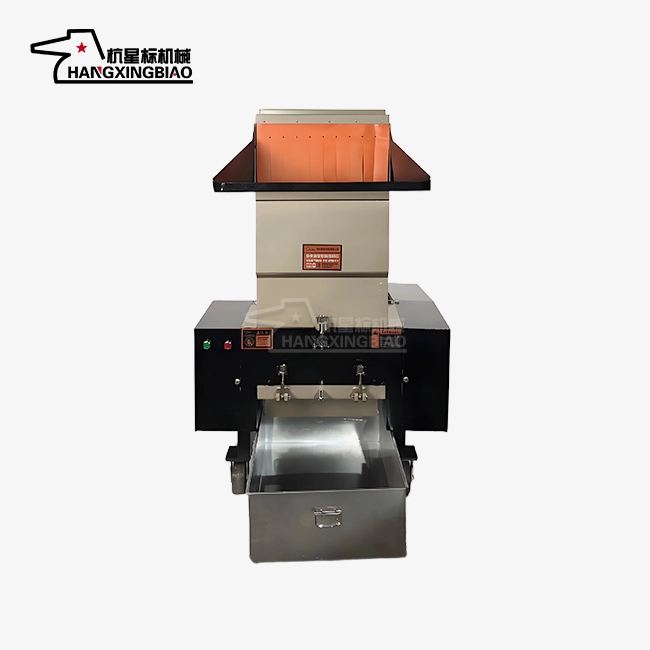

Enhanced Safety Features

Every machine includes comprehensive safety protection:

- Fully enclosed crushing chamber

- Anti-rebound baffles at feed inlet

- Safety interlocking devices

- Overload protection with automatic shutdown

Low Maintenance Design

The open plan permits simple get to for cleaning and upkeep. Quick-change screen structures minimize downtime, whereas uncovered upkeep focuses empower schedule assessment without total disassembly.

Comprehensive Product Range

Standard Models

Perfect for general plastic processing needs, offering reliable performance for medium-volume operations.

Heavy-Duty Crushers

Designed for large plastic parts, pipes, and profiles. These robust machines handle the toughest materials with ease.

Specialized Film Crushers

Custom Solutions

We develop tailored equipment for unique processing requirements, ensuring optimal performance for your specific applications.

Environmental and Economic Benefits

Immediate Waste Recycling

Transform production waste into reusable materials instantly. Mix crushed materials with virgin plastics at ratios of 30-50%, dramatically reducing raw material costs. This approach can save your company thousands of dollars annually while supporting environmental sustainability.

Quiet Operation

Operating noise levels remain below 75dB, making our equipment suitable for various environments including workshops and facilities with strict noise requirements.

Dust Control

Fully enclosed crushing chambers prevent dust leakage, maintaining clean working conditions and meeting environmental standards.

Technical Excellence and Innovation

Advanced Engineering Team

Our 20-member designing group persistently creates imaginative arrangements. We keep up organizations with driving companies to guarantee our innovation remains at the bleeding edge of industry standards.

Quality Assurance

Every component experiences thorough testing, counting energetic adjust confirmation to minimize vibration and guarantee steady operation. Our commitment to quality comes about in 40% lower disappointment rates compared to standard hardware.

Precision Manufacturing

Core components receive vacuum heat treatment and cryogenic processing, achieving hardness levels of HRC55-60. This translates to 3000-5000 hours of crushing life for typical plastic materials.

Contact Us

Choose Hangzhou Xingbiao Machinery for your pp crusher needs and experience the difference that three decades of specialized expertise makes. Contact us at postmaster@xingbiaocrusher.com to discuss your requirements and discover how our solutions can optimize your plastic processing operations while reducing costs and environmental impact.

Learn about our latest products and discounts through SMS or email