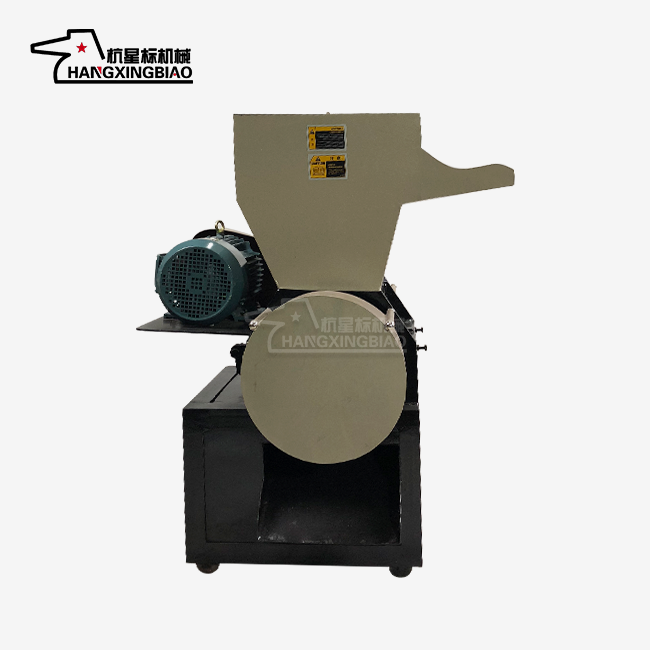

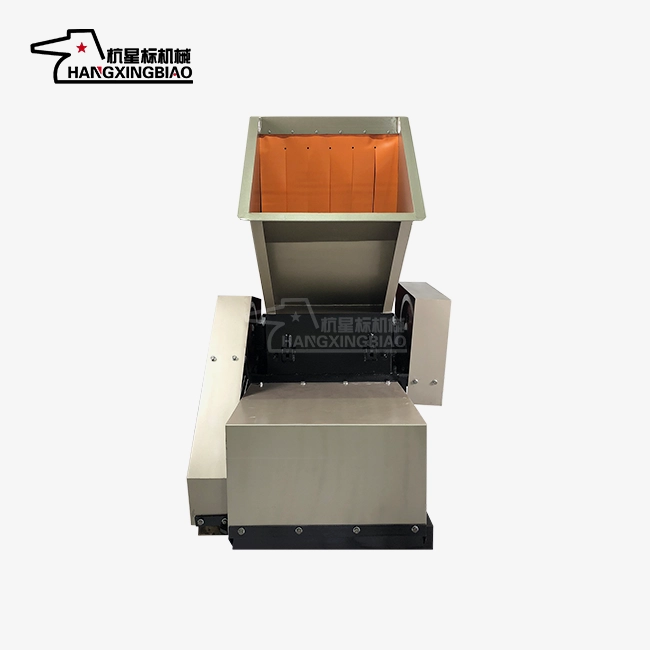

High-strength, stress-relieved steel ensures a deformation-free body. SKD-11 and D2 blades with vacuum and cryogenic treatment stay sharp longer, delivering efficient, reliable crushing with minimal downtime.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

chicken bone crusher

Chicken Bone Crusher - Professional Crushing Solutions for Your Business

Are you looking for a reliable chicken bone crusher that delivers consistent results? You've come to the right place. At Hangzhou Xingbiao Machinery Co., Ltd., we specialize in crushing equipment that handles the toughest materials with ease. Our bone crushing machines are designed to meet your specific processing needs, whether you're running a small operation or managing large-scale production. With over 30 years of focused expertise, we understand exactly what you need from your crushing equipment.

Why Choose Our Bone Crushing Equipment?

Built to Last, Designed to Perform

Superior Processing Capabilities

Our machines handle 50 kg–2 t/hour, supporting small batches or 24-hour continuous industrial operation to maximize productivity without equipment fatigue.

Smart Safety Features

Safety-focused design includes overload protection that shuts down on hard objects. Fully enclosed chambers contain dust and reduce noise below 75 dB, keeping operators safe and the workplace clean.

Advanced Crushing Technology

Efficient Design That Works

Unique blade layout boosts efficiency over 20%, with optimized cavity preventing jams. Adjustable screens (2–100 mm) allow precise particle size control for versatile applications.

Low Maintenance, High Reliability

Cutting tools with HRC 55–60 hardness last 3,000–5,000 hours and can be resharpened 3–5 times, reducing replacement costs by 60% versus standard carbon steel blades.

Energy Efficient Operation

Optimized motors and efficient transmissions cut energy use 10–15%, consuming only 8–12 kWh per ton while maintaining high capacity, keeping operating costs low during heavy use.

Comprehensive Model Range

Small to Large Scale Solutions

Mobile Units: Perfect for flexible operations. These compact units include wheels for easy movement between workstations.

Fixed Installation Models: Ideal for dedicated production lines. These medium-sized units offer the perfect balance of capacity and footprint.

Industrial Systems: Large-scale units that integrate with conveyor systems and automated production lines. Handle up to 10 tons per hour with ease.

Customization Available

Every operation has unique requirements. Our engineering team works with you to customize equipment specifications, ensuring your chicken bone crusher meets your exact needs.

We can modify capacity, particle size ranges, safety features, and integration capabilities. Your solution will be tailored specifically for your application.

Easy Operation and Maintenance

User-Friendly Design

Minimal training is needed thanks to clear controls. Quick-change screens allow particle size adjustments in minutes, usually without tools, enabling fast and efficient operation.

Simple Cleaning and Upkeep

Easily opened cavity allows thorough cleaning when switching materials. Accessible maintenance points enable quick inspections and lubrication, reducing maintenance costs by 50% compared to complex designs.

Proven Quality and Support

Three Decades of Expertise

With 30 years focused on crushing equipment, our 20-engineer team leverages industry partnerships to address challenges effectively and stay current with technological advances.

Complete Service Package

From consultation to support, our engineers offer selection advice, custom solutions, installation guidance, training, and follow-ups, with 24-hour responses to ensure maximum value from your investment.

Ready to Improve Your Processing?

Ready to learn more about how our chicken bone crusher can benefit your operation? Contact our team at postmaster@xingbiaocrusher.com for personalized consultation and detailed specifications.

Learn about our latest products and discounts through SMS or email