Stress-relieved steel prevents deformation, while treated SKD-11/D2 and Cr12MoV blades last 3000+ hours, allow 3–5 sharpenings, and cut costs.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

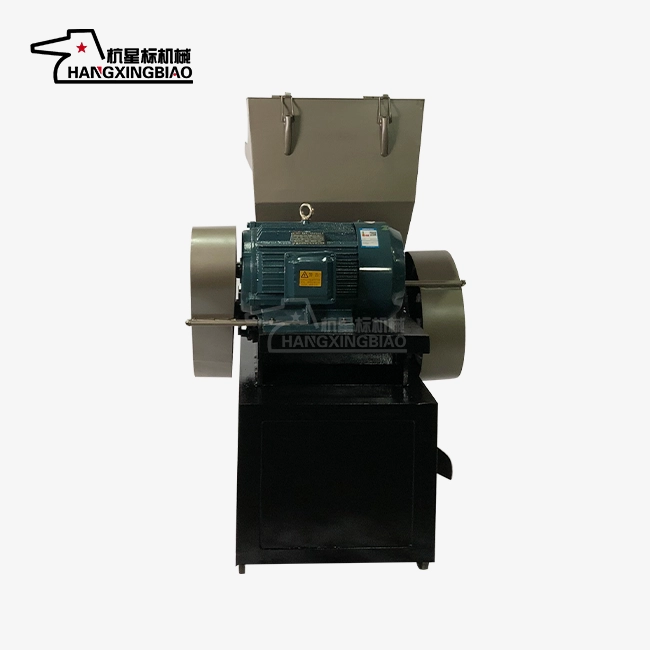

strong plastic crusher

Strong Plastic Crusher - Industrial Grade Plastic Recycling Solution

Are you struggling with plastic waste management in your facility? Our strong plastic crusher delivers exceptional performance for all your industrial crushing needs. Designed specifically for high-volume operations, this robust machine transforms plastic waste into valuable reusable materials with unmatched efficiency. Whether processing soft films, hard plastics, or irregular waste, our product adapts easily while maintaining consistent output quality.

What Makes Our Plastic Crusher Stand Out?

Unmatched Durability and Construction

Advanced Dual-Action Crushing Technology

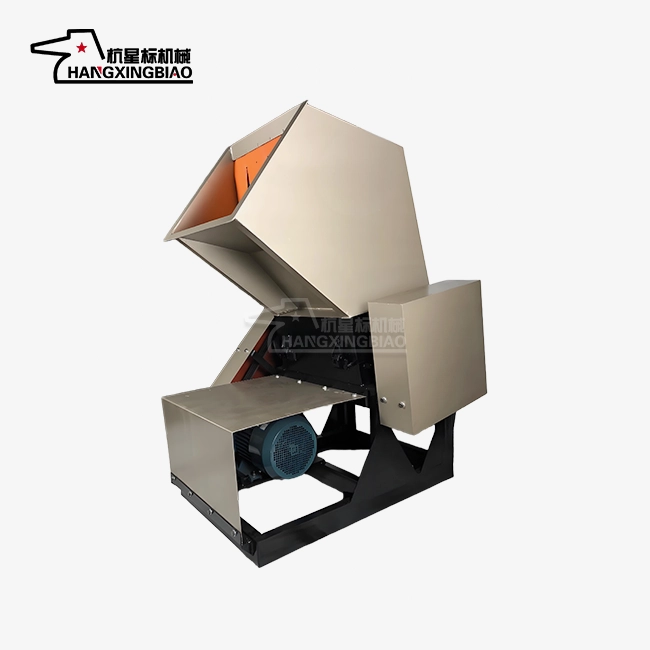

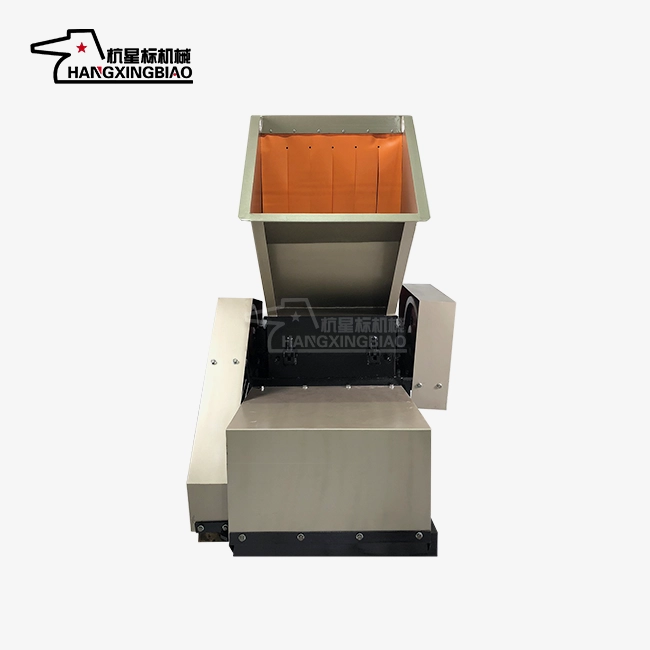

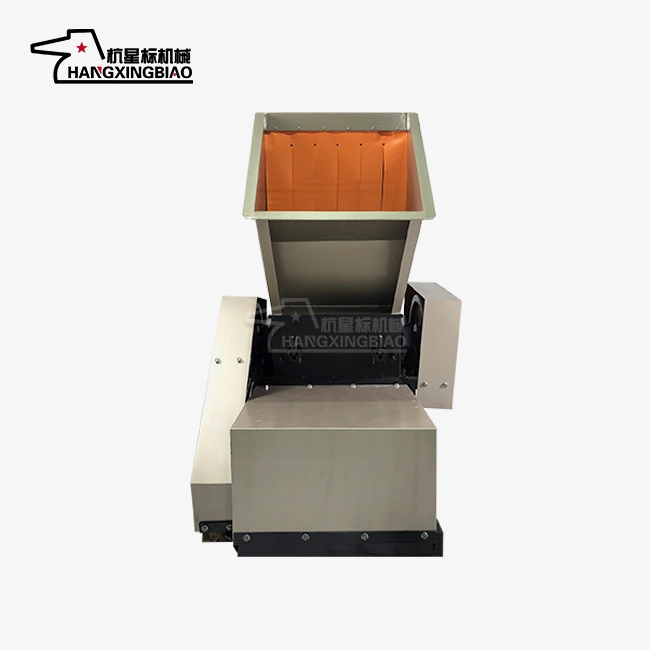

Our “shear + impact” process boosts efficiency, with optimized cavities and blade spacing preventing over-crushing and limiting powder. Discharge consistency exceeds 90%, eliminating secondary screening and reducing processing time and steps.

Wide Material Compatibility

Handle diverse plastic types without equipment changes:

- Soft plastics: PE/PVC films, woven bags, packaging materials

- Hard plastics: ABS/PC components, thick-walled pipes, automotive parts

- Foam materials: EPS/EVA buffer foam, insulation materials

- Irregular items: Plastic bottles, containers, production scraps

The built-in anti-winding comb design in this strong plastic crusher prevents jamming with fibrous materials. You process challenging materials like fabrics and films without interruption.

Precise Particle Size Control

Choose your output size with interchangeable screens from 2-100mm. Adjust blade speed for different crushing requirements. You get:

- Coarse fragments (5-50mm): Perfect for pretreatment processes

- Medium particles (2-12mm): Ideal for granulation and injection molding

- Fine particles: Suitable for specialized applications

Particle uniformity consistently exceeds 90% without additional sorting.

Comprehensive Model Range

Small to Medium Operations (50-500kg/hour)

Perfect for injection molding facilities and small recycling operations. These units handle runner material and production waste efficiently.

Industrial Scale Systems (1-10 tons/hour)

Designed for large recycling plants and high-volume manufacturers. Support 24-hour continuous operation with minimal maintenance requirements.

Customized Solutions

We build specialized units for unique needs, creating custom solutions for large-volume items like trash cans, bumpers, and industrial containers.

Energy Efficiency and Cost Savings

Advanced motor technology reduces energy consumption by 10-15% compared to traditional crushers. Processing one ton of plastic requires only 8-12 kWh of electricity.

Immediate scrap recycling saves substantial raw material costs. Crushed materials blend with virgin plastic at 30-50% ratios. This increases material utilization and reduces procurement expenses by thousands annually.

Safety and Reliability Features

Your team's safety comes first with this strong plastic crusher. Fully enclosed crushing chambers prevent material ejection. Anti-rebound baffles protect operators during feeding operations.

Selected models use interlock systems that cut power when the chamber opens. Precision bearings and hardened transmission parts ensure smooth, stable operation, while dynamic balancing keeps vibration under 0.1 mm and reduces failure rates by 40% versus standard models.

Maintenance Made Simple

Quick-access design minimizes downtime. Side panels remove easily for cleaning between different plastic types. This prevents color contamination in your recycled materials.

Key maintenance points remain accessible without full disassembly. Daily inspection and lubrication take minutes instead of hours. Maintenance time reduces by 50% compared to conventional designs.

Applications Across Industries

Manufacturing: Process runner material, rejected parts, and production waste immediately. Reduce raw material costs while maintaining quality standards.

Recycling Operations: Handle mixed plastic streams efficiently. Sort and process materials for resale to manufacturers.

Research and Education: Prepare standardized samples for material testing. Demonstrate plastic properties and recycling principles in educational settings.

Why Choose Hangzhou Xingbiao Machinery?

With 30 years dedicated to plastic crushing, we lead in crusher design. Our 20-engineer team works with major brands to keep technology aligned with real needs. You receive full support—from equipment selection to installation, training, and long-term technical service.

Response time for customer inquiries never exceeds 24 hours. Regular follow-up visits ensure optimal performance throughout your equipment's lifecycle.

Get Started Today

Contact our technical team at postmaster@xingbiaocrusher.com for detailed specifications and application guidance. We'll help you select the perfect strong plastic crusher for your specific requirements and budget.

Learn about our latest products and discounts through SMS or email