- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

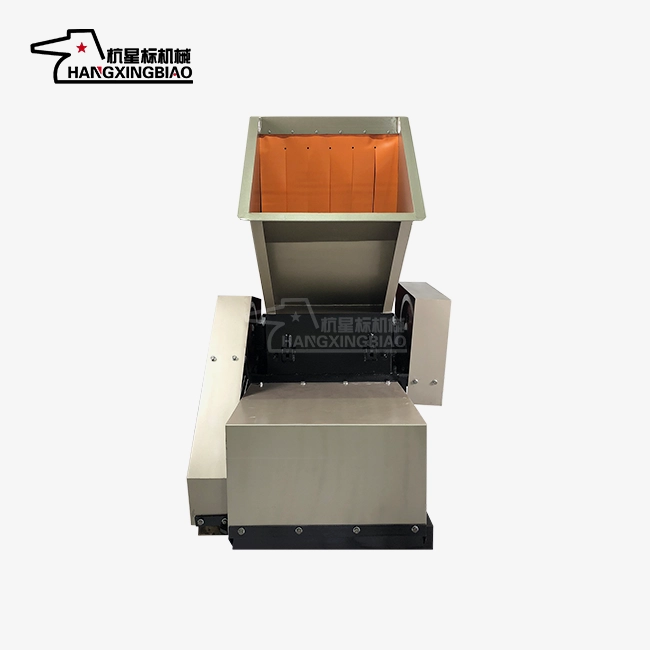

Plastic waste shredder

Plastic Waste Shredder - High-Efficiency Recycling Solution for Your Business

Transform Your Plastic Waste into Valuable Resources

Are you tired of watching valuable plastic waste pile up in your facility? Our advanced Plastic waste shredder offers the perfect solution for businesses seeking efficient recycling and cost reduction. This powerful machine transforms various plastic materials into reusable fragments, helping you save money while protecting the environment.

With decades of mastery in smashing innovation, Hangzhou Xingbiao Apparatus conveys dependable hardware that meets your particular preparing needs. Whether you're taking care of delicate movies or unbending plastic parts, our shredders adjust consistently to distinctive materials.

Why Select Our Plastic Destroying Solutions?

Superior Fabric Compatibility

Our machines handle numerous plastic types—from PE movies and woven sacks to ABS parts and foam—without consistent alterations. This wide compatibility kills the require for numerous units, sparing floor space and decreasing starting speculation costs.

Exceptional Preparing Efficiency

Our shredders provide steady execution from 50–500 kg/hour to 1–10 tons/hour. Optimized edge plan boosts effectiveness by 20% over conventional hardware, diminishing blockages and guaranteeing smoother, ceaseless operation all through your work shifts.

Precise Size Control

Our adjustable screening system delivers 2–50 mm particle sizes for different applications. With over 90% of output meeting target ranges, you get uniform results without secondary screening, ensuring smoother downstream processing.

Exceptional Blade Durability

Our SKD-11, D2, and Cr12MoV alloy blades receive specialized heat treatment for exceptional durability, lasting 3,000–5,000 hours with standard plastics. Each blade can be reground 3–5 times, reducing replacement costs by 60%.

Key Features That Benefit Your Operations

Immediate Waste Recovery

Stop throwing money away with plastic scraps. Our Plastic waste shredder processes runner materials, reject parts, and production waste instantly.

You can blend the recycled fragments with virgin materials at 30-50% ratios. This approach saves thousands of dollars annually in raw material costs while maintaining product quality.

Energy-Efficient Operation

Our optimized motor and transmission system lowers energy use by 10–15%, requiring only 8–12 kWh per ton of plastic. This efficient design keeps operating costs predictable and protects your profitability.

Comprehensive Safety Protection

The fully enclosed crushing chamber prevents material ejection, while safety interlocks cut power when doors open. This protects workers from moving parts and reduces injury risks.

Simple Maintenance Design

Our open design allows easy access to key components without full disassembly. Quick-change screens and exposed maintenance points cut service time by 50%, enabling operators to handle routine tasks with minimal training.

Flexible Model Options for Every Application

Portable Units

Our wheeled, compact units move easily between workstations, delivering on-demand crushing for small operations. They’re ideal for job shops, prototyping facilities, and sites with limited floor space.

Fixed Installation Models

Our medium-capacity fixed units integrate smoothly into production lines, delivering reliable handling of steady daily volumes. They’re ideal for manufacturers with dedicated recycling areas and consistent waste streams.

Integrated Production Systems

Large-scale operations require comprehensive solutions. Our high-capacity Plastic waste shredder units connect with conveyors, separators, and granulators.

These automated systems process massive volumes while minimizing labor requirements and maximizing throughput efficiency.

Built for Long-Term Reliability

Robust Construction

Heavy-duty steel plate welding and stress-relief treatment ensure long-term stability without deformation. Precision bearings and hardened transmission components keep operation smooth with minimal vibration and noise.

Quality Components

Every component meets strict standards, with dynamic balancing keeping vibration below 0.1mm to prevent wear and loosening. This reliable design reduces equipment failure rates by 40% compared to standard shredders.

Expert Support Throughout Your Journey

Ready to transform your plastic waste management strategy? Contact our specialists at postmaster@xingbiaocrusher.com to discuss your specific requirements and discover how our Plastic waste shredder solutions can enhance your operations while reducing costs.

Learn about our latest products and discounts through SMS or email