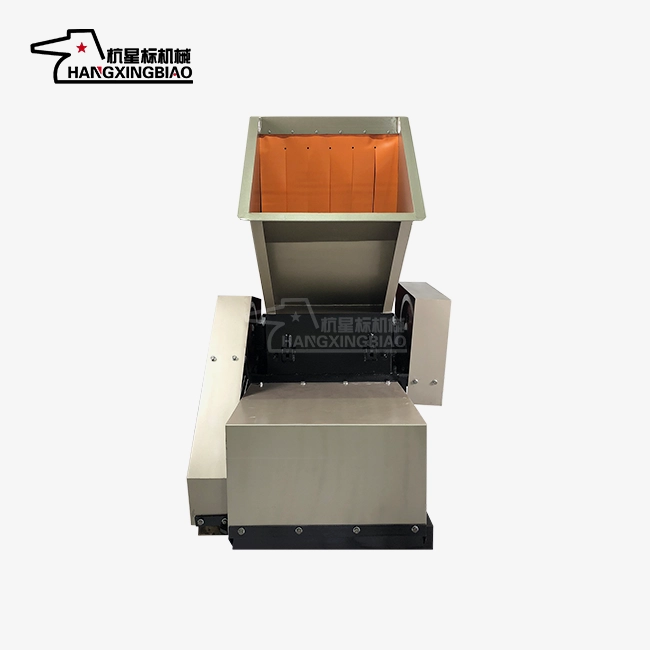

Our crushers use a “shear + impact” dual-action process with optimized cavity and blade spacing for discharge above 2 mm, preventing over-processing and powder waste. The anti-winding comb avoids jamming, while alloy cutting sets for hard plastics ensure over 3000 hours of reliable service.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

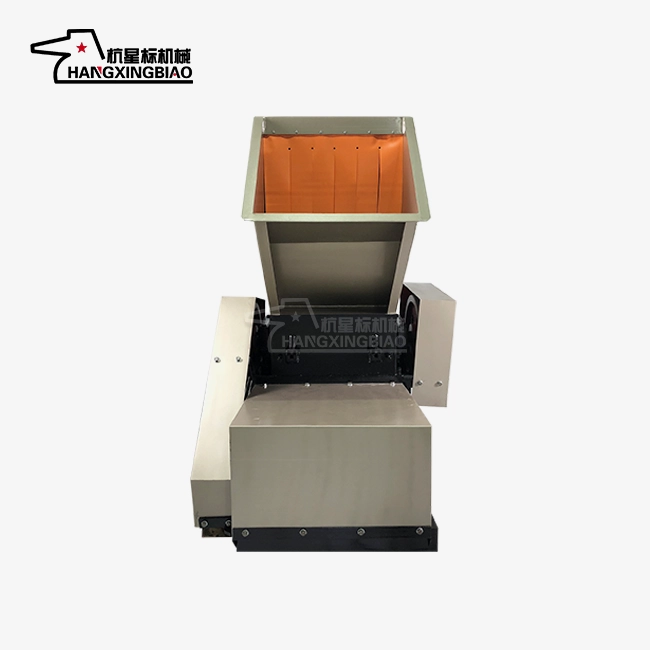

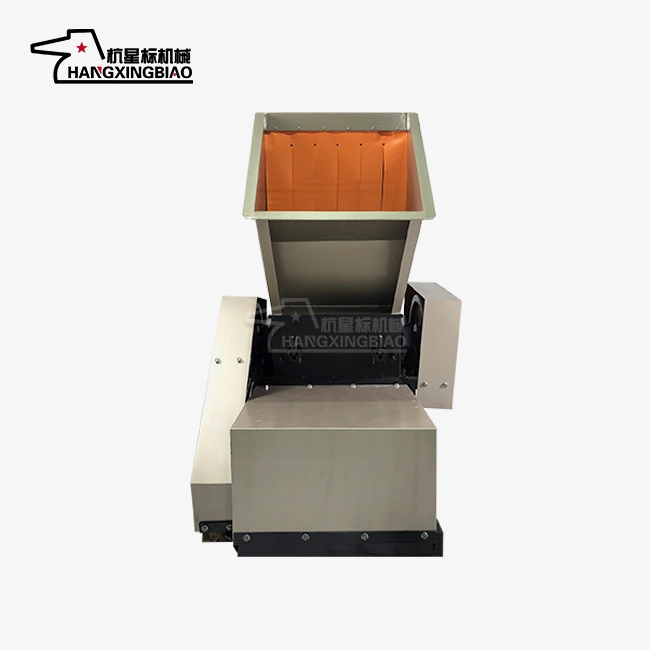

waste plastic crusher

Waste Plastic Crusher: Professional Solution for Plastic Recycling

Are you struggling with plastic waste management in your facility? Our waste plastic crusher from Hangzhou Xingbiao Machinery delivers the perfect solution for your recycling needs. With over 30 a long time of specialized skill, we've planned progressed smashing hardware that changes plastic squander into profitable reusable materials. This item combines cutting-edge innovation with strong development to handle differing plastic materials effectively. Whether you're preparing delicate movies or difficult plastic components, our machines guarantee reliable molecule estimate and greatest fabric recuperation for your operations.

Superior Crushing Technology for Maximum Efficiency

Wide Material Compatibility Meets Every Need

Your facility can process virtually any plastic type with our versatile equipment. Handle soft materials like PE films and woven bags alongside hard plastics such as ABS components and thick-walled pipes. The same machine processes foam materials, irregular shapes, and mixed plastic waste without requiring structural adjustments.

Processing capacity ranges from 50-500kg per hour for smaller operations to 1-10 tons per hour for industrial applications. Your production runs continuously for 24 hours while maintaining consistent output quality.

Precise Particle Control for Optimal Results

You control output particle size through interchangeable screening nets ranging from 2-100mm. Adjust blade speed or change cutting sets to produce coarse fragments (5-50mm) for pretreatment or medium particles (2-12mm) for granulation recycling.

Achieve over 90% particle uniformity without secondary screening. This precision eliminates additional processing steps while ensuring consistent material quality for your downstream applications.

Cost-Effective Operation with Durable Components

Our cutting systems use SKD11 and Cr12MoV alloy steels hardened to HRC55–60 for superior wear resistance and 3–5 resharpening cycles, cutting costs by 60%. They enable instant recycling of runners and waste, allowing 30–50% material reuse and significant annual savings.

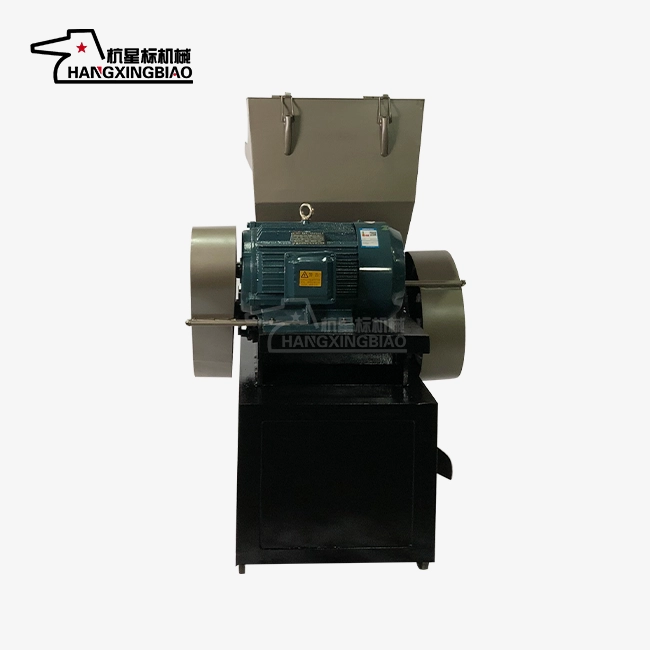

Energy Efficient Design Reduces Operating Expenses

Optimized motor and transmission systems reduce energy consumption by 10-15% compared to traditional equipment. Processing one ton of plastic requires only 8-12 kilowatt hours. This efficiency translates directly to lower operating costs for your facility.

The waste plastic crusher features precision bearings and hardened gears with regular lubrication systems. Dynamic balance testing ensures vibration levels below 0.1mm, reducing component wear and extending equipment life.

Safety Features Protect Your Operators

Fully enclosed protection with steel plates, anti-rebound baffles, and safety shields ensures operator safety. Interlocking systems cut power during access, while easy maintenance points reduce downtime by 50%.

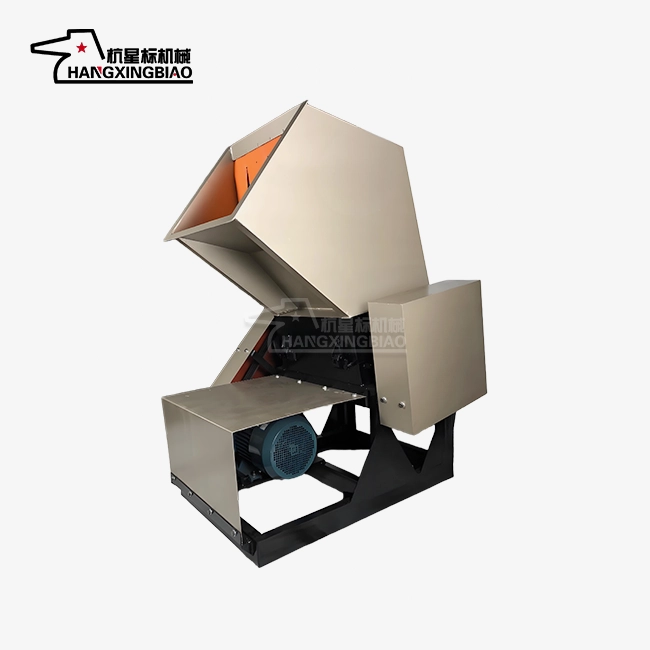

Flexible Models for Every Application

Choose from mobile units with universal wheels for flexible positioning, fixed installations for dedicated production lines, or integrated systems linking with granulators and conveyors. Models scale from laboratory testing at 50kg/h to large recycling operations at 10t/h capacity.

Quick-disassembly side panels facilitate easy cleaning when switching between different colored plastics. This prevents color contamination while maintaining production flexibility across varied material types.

Professional Support Throughout Your Journey

Ready to transform your plastic waste into valuable resources? Contact our specialists at postmaster@xingbiaocrusher.com today. Discover how the right waste plastic crusher can optimize your recycling operations while reducing costs and environmental impact.

Learn about our latest products and discounts through SMS or email