Our crushers handle soft PE films, woven bags, hard ABS parts, thick pipes, and foam without multiple machines, saving space, cost, and operational complexity.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

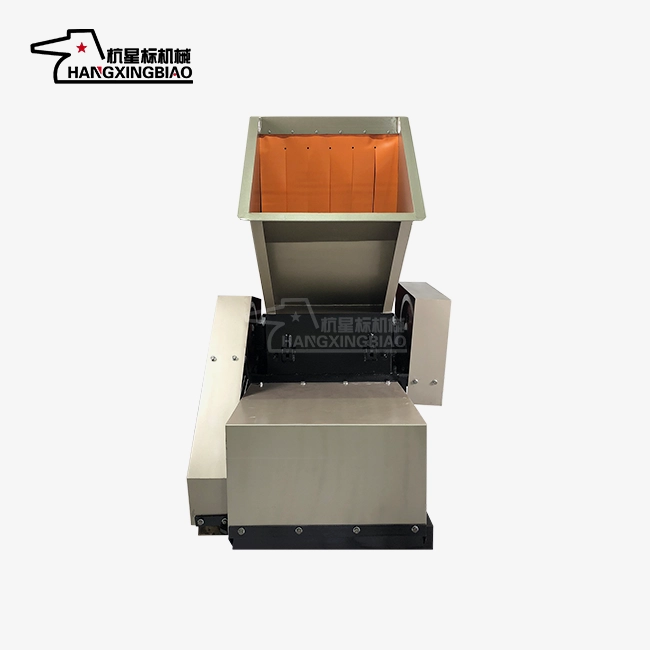

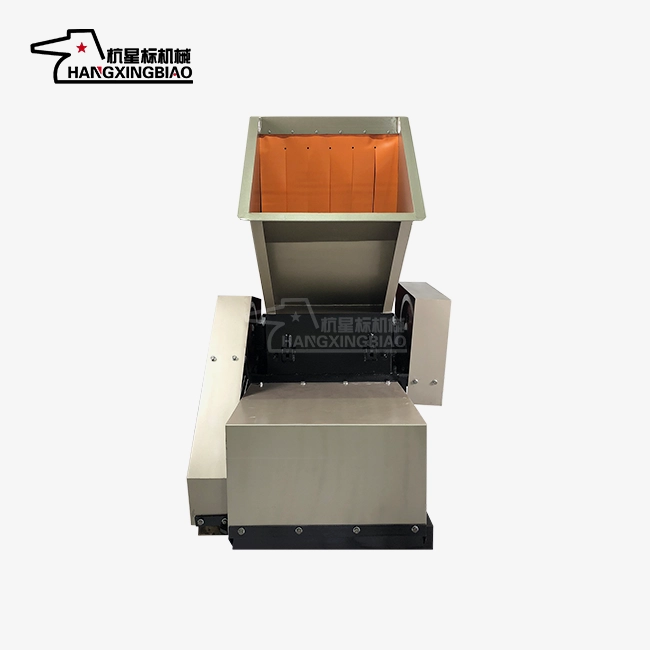

Powerful crusher

Powerful Crusher: Advanced Plastic Shredding Solutions for Your Production Needs

Are you looking for a reliable and efficient solution to handle your plastic waste? Our powerful crusher from Hangzhou Xingbiao Machinery delivers exceptional performance that transforms waste into valuable resources. With 30 years of specialized expertise in plastic crushing technology, we understand exactly what your operation needs. This advanced crushing system combines cutting-edge engineering with practical design. You get superior results every time you use it.

Why Choose Our High-Performance Crushing Equipment?

Unmatched Versatility Across Materials

Superior Crushing Technology

Our "shear + impact" process optimizes cavity and blade spacing for 2 mm+ discharge, preserving particle integrity. Anti-winding combs prevent jams with fibrous materials, ensuring smooth, uninterrupted operation.

Exceptional Processing Efficiency

Small units handle 50–500 kg/hour, industrial 1–10 t/hour, running 24/7. Optimized design boosts efficiency 15–20%, processing more material faster while using less energy.

Precision Particle Control

Different applications require different particle sizes in the Powerful crusher. Simply change the screening mesh (2–100 mm options available) to achieve your desired output. Coarse fragments work perfectly for pretreatment processes. Medium particles suit granulation and injection recycling perfectly.

Particle uniformity exceeds 90%. You eliminate secondary screening steps and reduce processing time significantly.

Built for Durability and Cost Savings

Long-Lasting Blade Performance

Blades made from SKD-11, D2, and Cr12MoV steels undergo vacuum and cryogenic treatment, reaching HRC 55–60. They last 3,000–5,000 hours and can be reground 3–5 times, cutting replacement costs 60% versus carbon steel.

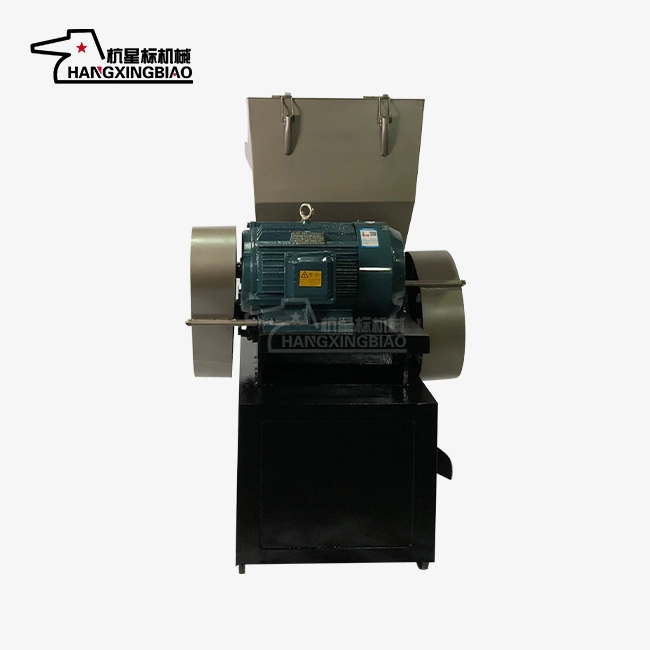

Energy-Efficient Operation

Our "efficient motor + optimized transmission" design reduces energy consumption by 10-15%. Processing one ton of plastic requires only 8-12 kWh. Lower operating costs improve your bottom line significantly.

Immediate Material Recovery

Transform production waste into valuable resources instantly. Crush nozzle materials and production scraps immediately. Mix recycled material with new plastic at 3:7 or 5:5 ratios safely.

Raw material utilization increases by 30-50%. This saves thousands in procurement costs annually while supporting sustainability goals.

Safety and Reliability First

Comprehensive Protection Systems

Thick steel chambers with anti-rebound baffles and external shields ensure durability and safety. Select models feature "open and stop" interlocks that cut power when opened, preventing operator injuries.

Rock-Solid Stability

Precision bearings and hardened gears ensure smooth transmission. Regular lubrication and dynamic balancing (<0.1 mm) reduce wear and vibration, lowering failure rates 40% for uninterrupted, efficient production.

Complete Range for Every Application

Flexible Configuration Options

Choose mobile units with universal wheels for multi-station flexibility. Fixed models suit dedicated production lines perfectly. Integrated systems link with granulators and conveyors for complete automation.

Our powerful crusher models cover laboratory testing (50kg/h) through large recycling operations (10t/h). Custom configurations meet your specific requirements exactly.

Simple Maintenance Design

Quick-removal side panels allow easy cleaning and prevent color contamination. Accessible maintenance points enable inspections and lubrication without full disassembly, reducing maintenance time by 50%.

Proven Engineering Excellence

Our 20-member engineering team brings decades of specialized experience. Industry partnerships with companies like Nongfu Spring validate our technical capabilities. We focus exclusively on crushing technology advancement.

High-strength steel construction undergoes stress relief treatment. This prevents deformation during extended operation periods. Robust welding ensures long-term structural integrity.

Your Next Step Toward Efficient Processing

Ready to experience the difference our powerful crusher technology makes? Contact our engineering team for personalized consultation and solution development. Reach us at postmaster@xingbiaocrusher.com to discuss your specific requirements.

Learn about our latest products and discounts through SMS or email