Our machines use high-strength, stress-relieved steel for deformation-free 24-hour operation. Premium SKD-11/D2 blades, treated with vacuum and cryogenic processes, stay sharp for 3,000–5,000 hours, cutting replacement costs by 60%.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

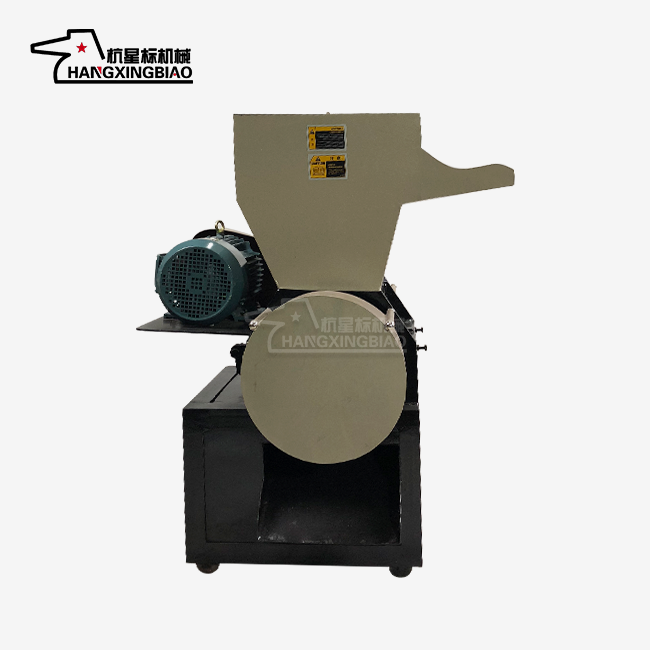

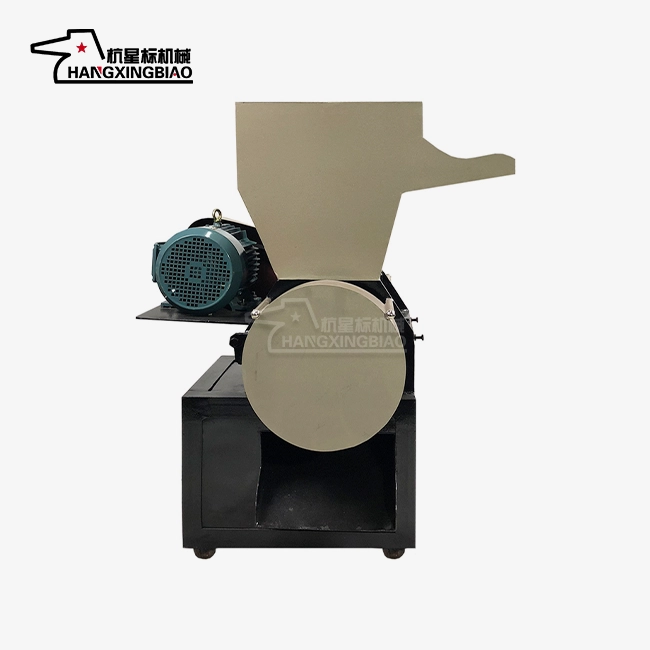

Large plastic bottle crusher

Large Plastic Bottle Crusher - Heavy-Duty Industrial Shredding Solution

Are you struggling with plastic bottle waste management? A Large plastic bottle crusher transforms your waste disposal challenge into a recycling opportunity. At Hangzhou Xingbiao Machinery Co., Ltd., we've dedicated 30 years exclusively to plastic crushing technology. Our specialized equipment efficiently processes plastic bottles of all sizes, from small beverage containers to large industrial containers. With our crusher, you'll reduce waste volume by up to 80% while creating reusable plastic material. This equipment pays for itself through reduced disposal costs and material recovery value within months of installation.

Why Choose Our Heavy-Duty Bottle Processing Equipment?

Superior Build Quality You Can Trust

Exceptional Processing Efficiency

Your production needs vary throughout the day. Our equipment adapts with processing capacities ranging from 50kg to 2,000kg per hour. Whether you're processing beverage bottles, milk jugs, or chemical containers, the Large plastic bottle crusher maintains consistent output.

The unique blade layout increases crushing efficiency by over 20%. You'll process more material using less energy. Our optimized motor matching reduces power consumption by 15% compared to traditional designs.

Versatile Material Handling

Different bottle types require different processing approaches. Our crusher handles:

- Soft plastic bottles: PE milk jugs, squeezable containers

- Hard plastic bottles: PET beverage bottles, chemical containers

- Large containers: Industrial drums, storage tanks

- Mixed bottle streams: Various bottle types simultaneously

You won't need multiple machines for different materials. One crusher handles your entire bottle processing needs.

Advanced Safety and Environmental Features

Comprehensive Protection Systems

Safety is prioritized through a fully enclosed chamber, anti-rebound baffles, and an open-and-stop interlock that cuts power instantly. Built-in overload protection detects jams or metal contamination, shutting down the system to prevent damage and extend equipment life.

Quiet, Clean Operation

Operating noise stays below 75dB, suitable for workshop environments. The enclosed design prevents dust leakage, maintaining clean working conditions. Your facility meets environmental compliance standards without additional investments.

Customizable Output for Your Applications

Precise Size Control

Different applications require specific particle sizes. Simply change the screening mesh to achieve:

- Coarse fragments (5-50mm): Pre-treatment for further processing

- Medium particles (2-12mm): Direct granulation or injection molding

- Fine particles (2-5mm): Specialized applications

Particle uniformity exceeds 90%, eliminating secondary screening needs. You'll save processing steps and labor costs.

Immediate Material Recovery

Process bottles directly at your production line. The Large plastic bottle crusher enables immediate recycling of production waste. Mix crushed material with virgin plastic at ratios up to 50:50. This approach reduces raw material costs by 30-50% annually.

Easy Maintenance and Long-Term Value

Simple Maintenance Design

Key maintenance points remain easily accessible. Daily inspection and lubrication require no machine disassembly. The quick-change screen structure minimizes downtime during size changes.

Precision bearings and hardened gears ensure smooth operation. Regular lubrication points reduce mechanical wear. Vibration stays below 0.1mm, preventing component loosening.

Flexible Installation Options

Choose from three installation configurations:

- Mobile units: Universal wheels allow movement between workstations

- Fixed installations: Floor-mounted for dedicated production lines

- Integrated systems: Link with conveyors and granulators for automation

Your specific facility layout determines the best configuration. We'll recommend the optimal setup for your operations.

Comprehensive Support and Service

The Large plastic bottle crusher offers multiple model options covering various processing requirements. Contact us at postmaster@xingbiaocrusher.com to discuss your specific bottle processing challenges and receive customized solution recommendations.

Learn about our latest products and discounts through SMS or email