Our crushers use high-strength steel with stress relief and SKD-11/Cr12MoV blades treated by vacuum heat and cryogenic processes. With HRC55–60 hardness and 3000–5000-hour blade life, they deliver strong wear resistance, stable continuous performance, reduced maintenance, and minimal downtime.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

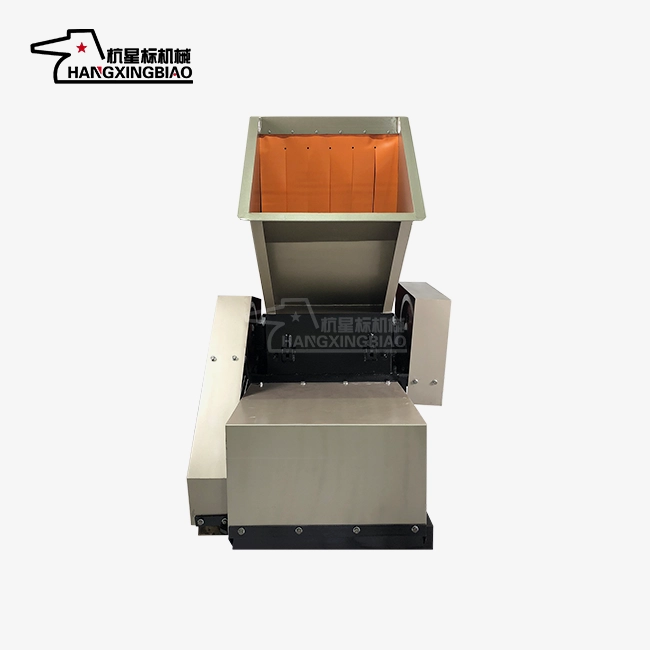

water bottle crushing machine

Water Bottle Crushing Machine - Professional Plastic Recycling Solution

Are you looking for an efficient water bottle crushing machine to streamline your plastic recycling operations? Our progressed pulverizing hardware changes plastic bottles into uniform particles, maximizing your reusing productivity whereas decreasing squander administration costs. With over 30 a long time of specialized involvement in plastic pulverizing innovation, Hangzhou Xingbiao Apparatus conveys solid, high-performance arrangements that meet differing mechanical needs. Our machines handle different bottle sorts easily, guaranteeing steady yield quality for your generation requirements.

Why Choose Our Bottle Crushing Equipment?

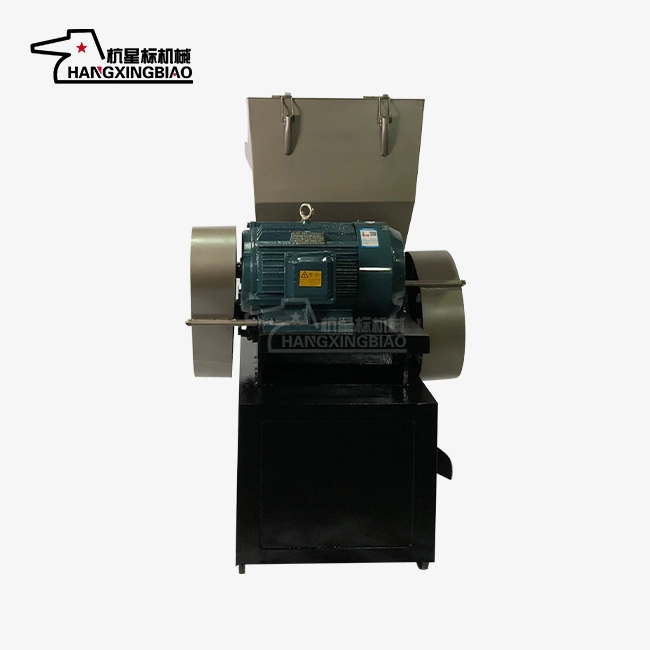

Superior Build Quality and Durability

Enhanced Processing Efficiency

Our optimized design boosts productivity, with a unique blade layout and chamber raising efficiency by over 20%. Energy-efficient motors cut power use while maintaining high throughput.

Processing capacity ranges from 50kg/h for smaller operations to 10 tons/h for industrial applications. This water bottle crushing machine operates continuously for 24-hour production cycles, meeting demanding recycling schedules without compromising quality.

Versatile Material Compatibility

Beyond water bottles, our equipment handles diverse plastic materials including:

- PET and HDPE bottles

- Plastic containers and jugs

- Rigid plastic packaging

- Mixed plastic waste streams

The machine processes both soft and hard plastics effectively. You won't need multiple units for different material types, saving space and investment costs.

Precise Particle Size Control

Achieve consistent output with adjustable screening systems. Screen mesh options range from 2mm to 50mm, allowing precise particle size control. This flexibility supports various downstream applications including:

- Plastic pelletizing operations

- Recycled material blending

- Waste-to-energy preparation

- Secondary processing requirements

Particle uniformity exceeds 90%, eliminating secondary screening needs and improving overall efficiency.

Key Technical Features

Advanced Safety Systems

Our hardware guarantees security with an encased chamber, anti-rebound confuses, and interlocks that stop operation when entryways open, anticipating spillage, shots, and coincidental contact amid upkeep.

Easy Maintenance Design

Simplified maintenance reduces operational costs significantly. The open chamber design allows quick access to cutting components. Screen changes take minutes rather than hours, minimizing production interruptions.

Key maintenance points of the water bottle crushing machine remain easily accessible without full machine disassembly. Regular lubrication and inspection tasks complete 50% faster than conventional designs.

Low Energy Consumption

Efficient motors and optimized transmission use only 8–12 kWh per ton, saving 10–15% versus traditional systems while cutting operating costs, maintaining high throughput, and boosting recycling profitability.

Applications and Benefits

Industrial Recycling Operations

Large recycling facilities benefit from our high-capacity models. Continuous operation capability handles substantial material volumes efficiently. Consistent particle size output improves downstream processing quality.

Manufacturing Waste Recovery

Plastic manufacturers reduce waste disposal costs by processing production scraps immediately. The crushed material blends with virgin plastic at 30-50% ratios, significantly reducing raw material expenses.

Custom Solutions Available

We provide tailored configurations for specific requirements. Mobile units offer flexibility for multiple processing locations. Fixed installations integrate seamlessly with existing production lines.

Expert Engineering Support

Our 20 senior engineers provide full technical support from consultation to installation and training. Partnerships with leaders like Nongfu Spring and KFC reflect our commitment to quality and ensure our technology meets real-world operational demands.

Response times for technical inquiries average under 24 hours. Installation support, operator training, and ongoing maintenance assistance keep your equipment performing optimally.

Investment Returns

Your water bottle crushing machine investment delivers both environmental benefits and financial returns. Contact our technical team at postmaster@xingbiaocrusher.com for detailed specifications and customized recommendations that match your specific processing requirements perfectly.

Learn about our latest products and discounts through SMS or email