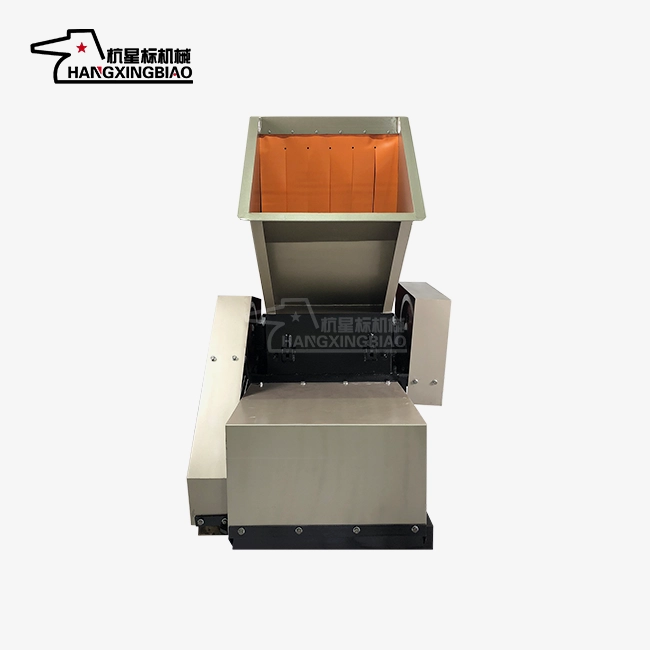

The chamber uses stress-relieved steel plates to prevent deformation, with anti-rebound baffles and external shields. Advanced models include open-and-stop interlocks for enhanced operator safety.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Plastic recycling crusher

Industrial Plastic Recycling Crusher for Efficient Material Processing

Transform Your Plastic Waste into Valuable Resources

Are you struggling with mounting plastic waste in your production facility? Our industrial plastic recycling crusher delivers the perfect solution for your material processing needs. Planned with cutting-edge innovation and built for greatest productivity, this effective gear changes different plastic materials into steady, reusable particles. With over 30 a long time of specialized encounter in plastic pulverizing innovation, Hangzhou Xingbiao Apparatus Co., Ltd. brings you gear that handles everything from delicate movies to unbending components with exceptional accuracy and unwavering quality.

Why Choose Our Advanced Crushing Technology?

Exceptional Material Compatibility

Your production line deals with diverse plastic types daily. Our crusher handles soft materials like PE/PVC films and woven bags, rigid plastics including ABS and PC components, foam materials such as EPS buffer foam, and irregular shapes like bottles and trays. You won't need multiple machines for different materials.

Superior Processing Performance

Processing capacity ranges from 50-500kg per hour for compact models to an impressive 1-10 tons hourly for industrial units. The equipment supports continuous 24-hour operation without performance degradation. You'll achieve 15-20% higher efficiency compared to traditional crushing equipment.

Precision Particle Size Control

Customize your output with interchangeable screening nets ranging from 2-100mm openings. Whether you need coarse fragments for pretreatment (5-50mm) or fine particles for injection molding (2-12mm), particle uniformity consistently exceeds 90%. No secondary screening required.

Built for Durability and Cost Efficiency

Premium Tool Construction

Core cutting components utilize premium alloy materials including SKD-11, D2 mold steel, and Cr12MoV special steels. Through vacuum heat treatment and cryogenic processing, blade hardness reaches HRC55-60. Your plastic recycling crusher operates for 3000-5000 hours before tool replacement becomes necessary.

Significant Cost Savings

Transform production waste into valuable resources immediately. Crushed materials blend seamlessly with virgin plastic at ratios of 30-50%, reducing raw material costs by thousands annually. Tools support repeated sharpening 3-5 times, cutting replacement expenses by 60%.

Energy-Efficient Operation

Our optimized motor and transmission design reduces power consumption by 10-15% compared to conventional equipment. Processing one ton of plastic material requires only 8-12 kWh, keeping operational costs minimal.

Safety and Reliability Features

Comprehensive Protection Systems

Minimal Maintenance Requirements

Precision bearings and hardened gear transmission systems ensure smooth operation with regular lubrication schedules. Dynamic balance testing reduces vibration to ≤0.1mm, preventing component loosening. Equipment failure rates drop 40% below industry averages.

Flexible Configuration Options

Versatile Model Range

Choose from mobile Plastic recycling crusher units with universal wheels for flexible positioning, fixed installations for permanent production lines, or integrated systems linking with granulators and conveyors. Capacity options span from laboratory testing (50 kg/h) to large-scale recycling operations (10 t/h).

Quick Maintenance Access

Simple chassis design allows rapid cavity disassembly for thorough cleaning between different plastic types. Key maintenance points remain easily accessible without complete machine disassembly, reducing service time by 50%.

Proven Engineering Excellence

Our research and development team of 20 senior engineers maintains industry partnerships with leading companies. This collaboration drives continuous innovation in crushing technology. The product represents decades of specialized focus on single-category excellence.

High-strength, stress-relieved steel ensures stability. Optimized blade layout and cavity boost efficiency and lower energy use, while quick-change screens and open-access design minimize downtime.

Professional Support and Service

Ready to optimize your plastic processing efficiency? Contact our engineering team at postmaster@xingbiaocrusher.com for detailed specifications and custom configuration options. Experience the difference that specialized expertise and proven technology bring to your plastic recycling crusher operations.

Learn about our latest products and discounts through SMS or email