No frequent equipment changes or complex adjustments needed in the Plastic waste crusher. One machine handles multiple crushing scenarios seamlessly.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

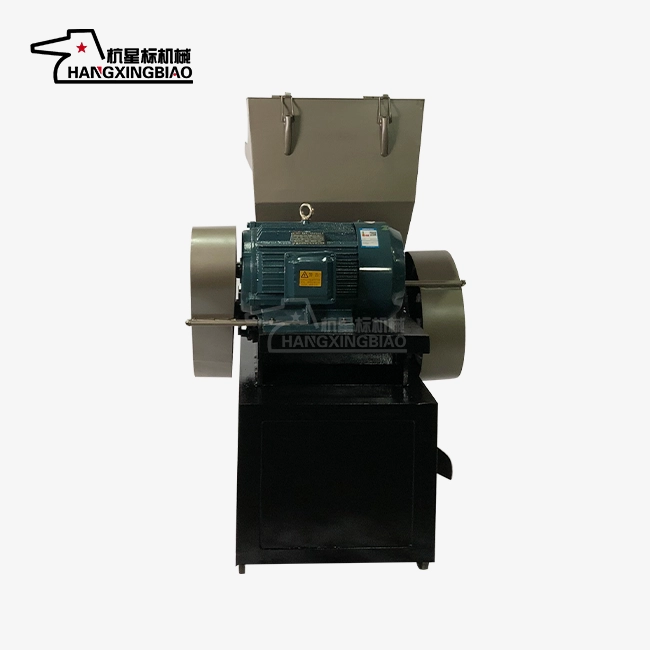

Plastic waste crusher

Plastic Waste Crusher: Professional Solution for Efficient Plastic Recycling

Looking for a reliable product to handle your recycling needs? You've come to the right place. Our plastic waste crusher delivers exceptional performance for processing various plastic materials, from soft films to hard plastic parts. Whether you're running a small processing facility or managing large-scale recycling operations, this equipment offers the perfect balance of efficiency, durability, and cost-effectiveness. With over 30 years of specialized experience, we understand exactly what your business needs.

Why Choose Our Product?

Superior Build Quality

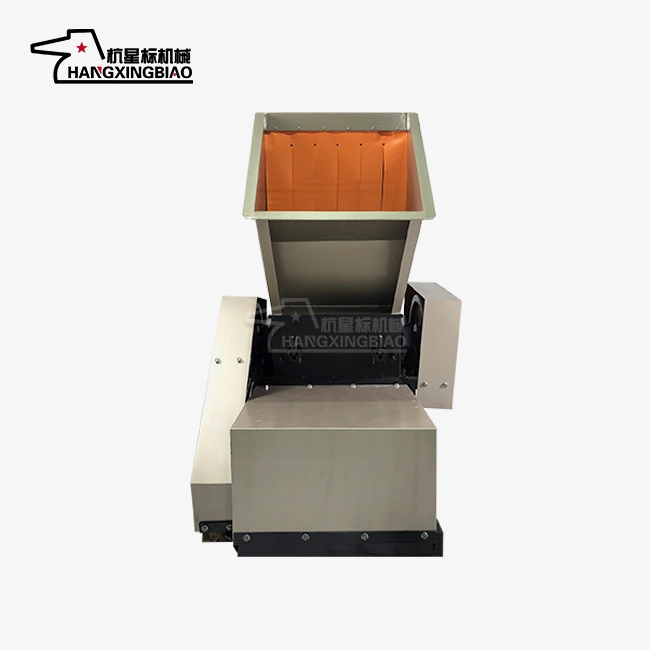

Our crushers use heavy-duty, stress-relieved steel plates to maintain precision over thousands of hours. SKD-11/D2 and Cr12MoV blades receive heat and cryogenic treatment, achieving HRC55–60 hardness and delivering 3000–5000 hours of wear-resistant performance.

Remarkable Efficiency Gains

Our blade layout and optimized cavity design boost efficiency by over 20%, processing more material with less energy. Capacity ranges from 50–500 kg/h to 10 tons/h, while optimized motors cut energy use 10–15%, requiring only 8–12 kWh per ton.

Versatile Material Handling

Your plastic waste varies daily, and your equipment should adapt accordingly. Our crusher easily processes:

- Soft plastics: PE/PVC films, woven bags, and flexible packaging

- Hard plastics: ABS/PC parts, thick-walled pipes, and rigid containers

- Foam materials: EPS/EVA cushioning and insulation foam

- Irregular items: Plastic bottles, trays, and production scraps

Precision Particle Size Control

Achieving consistent output size matters for your downstream processes. Simply change the screening mesh (2-100mm options available) to get exactly what you need:

- Coarse fragments (5-50mm): Perfect for pretreatment applications

- Medium particles (2-12mm): Ideal for granulation and injection molding recycling

- Fine processing: Achieves 90%+ particle uniformity without secondary screening

Smart Design Features

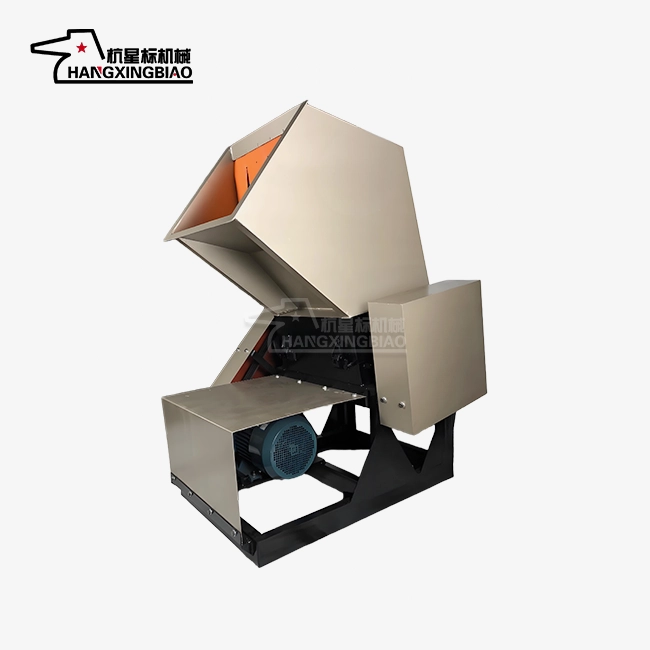

Quick Maintenance Access

Our open design provides easy access to critical components, with quick-change screens and exposed maintenance points eliminating full disassembly. Maintenance time drops 50%, and cleaning between different plastic colors takes only minutes.

Safety First Approach

Worker safety comes first with a fully enclosed, thick steel chamber and anti-rebound baffles that prevent kickback. Select models include open-and-stop interlocks that cut power when the chamber is accessed, preventing accidental injuries during maintenance.

Stable Operation

Precision bearings and hardened gears ensure smooth operation even under heavy loads. Our dynamic balance testing keeps vibration below 0.1mm, preventing component loosening and extending equipment life.

Regular lubrication points make maintenance straightforward in the Plastic waste crusher, while the robust transmission system reduces failure rates by 40% compared to standard models.

Complete Model Range

We offer three main configurations to match your specific needs:

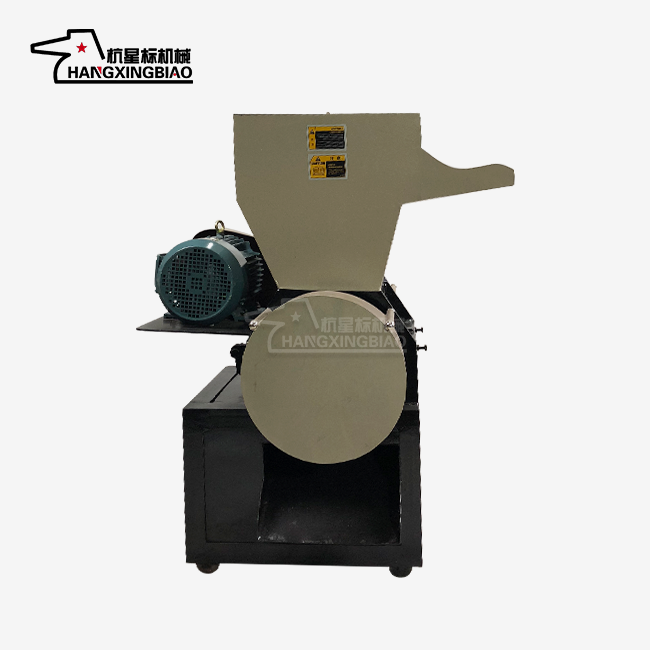

Mobile Units: Compact design with universal wheels for flexible positioning across different work stations. Perfect for smaller operations requiring equipment mobility.

Fixed Installation: Medium-capacity machines designed for permanent floor mounting. Ideal for established production lines with consistent throughput requirements.

Integrated Systems: Large-capacity units that link directly with granulators, conveyor belts, and automated feeding systems. Perfect for high-volume recycling facilities.

Coverage ranges from laboratory testing (50kg/h) to industrial recycling plants (10t/h).

Immediate Cost Benefits

Start saving immediately by processing scraps, runners, and rejected parts on-site. Mix recycled material with virgin plastic at 30–50% ratios to boost utilization by 30–50%, cut material costs significantly, and achieve ROI within 6–12 months.

Technical Specifications

Transmission Options:

- Belt drive: Suitable for small to medium models, provides impact cushioning and motor protection

- Direct drive: Used in large industrial models, achieves 95%+ transmission efficiency with superior stability for continuous operation

Both configurations deliver reliable performance tailored to specific capacity requirements and operating conditions.

Your Next Step

Ready to transform your plastic waste into valuable recycled material? Our engineering team stands ready to help you select the perfect plastic waste crusher for your specific requirements. Contact us at postmaster@xingbiaocrusher.com for professional consultation and customized solutions that match your processing needs exactly.

Learn about our latest products and discounts through SMS or email