Our machines use stress-relieved high-strength steel and SKD-11/D2/Cr12MoV blades with vacuum and cryogenic treatment, ensuring reliable, deformation-free, and highly durable operation.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

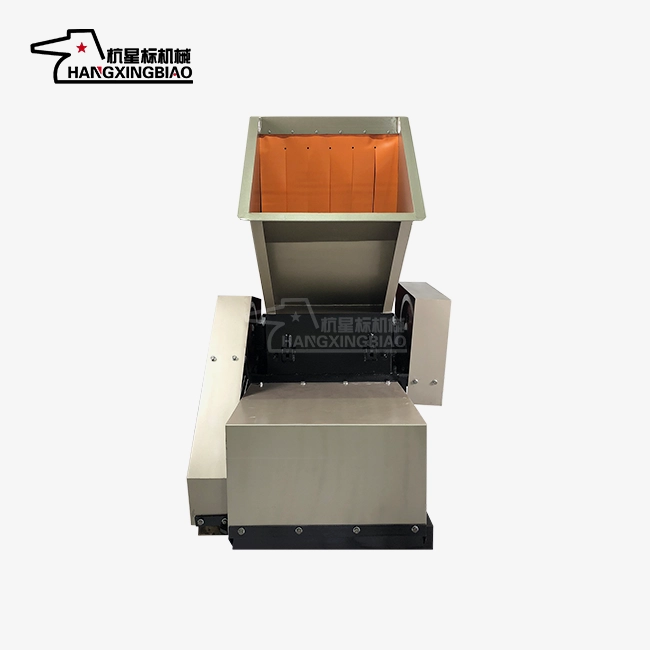

Garbage shredder

Transform Your Waste Management with Our Professional Garbage Shredder

Are you tired of mounting waste disposal costs and inefficient recycling processes? Our industrial Garbage shredder offers the perfect solution for businesses seeking reliable, cost-effective waste reduction. This capable machine changes bulky squander into reasonable particles, significantly diminishing transportation costs and capacity space necessities. With over 30 a long time of specialized designing encounter, Hangzhou Xingbiao Apparatus conveys uncommon pulverizing execution you can believe. Our item handles assorted materials effectively, making it perfect for reusing centers, fabricating offices, and squander administration companies.

Why Choose Our Waste Shredding Solutions?

Superior Engineering and Materials

Impressive Processing Capabilities

Whether you're handling 50kg per hour or need industrial-scale 10-ton capacity, our machines adapt to your requirements. You'll achieve 15-20% higher efficiency compared to traditional equipment, with particle sizes ranging from 2-100mm depending on your specific needs. The uniform output quality exceeds 90%, eliminating secondary screening requirements.

Wide Material Compatibility

Our shredders excel with various waste types:

- Soft plastics: Films, woven bags, packaging materials

- Hard plastics: Containers, automotive parts, thick-walled components

- Mixed waste: Cartons, bottles, composite materials

- Organic waste: Agricultural residues, food processing byproducts

Energy-Efficient Operation

Smart engineering reduces your operating costs significantly. Our optimized motor and transmission design cuts energy consumption by 10-15% compared to conventional shredders. Processing one ton of material typically requires only 8-12 kilowatt-hours, keeping your electricity bills manageable.

Advanced Safety Features

Your team's safety remains our top priority in the Garbage shredder. Every machine includes fully enclosed crushing chambers with anti-rebound baffles and comprehensive safety shields. Selected models feature automatic power cut-off systems that activate when chambers open, preventing accidental injuries during maintenance or cleaning.

Versatile Model Options

Mobile Units

Perfect for smaller operations requiring flexibility. These compact units include universal wheels, allowing easy movement between different work stations. Ideal for businesses processing 50-500kg daily.

Fixed Installation Models

Medium-capacity machines designed for permanent production line integration. These units provide consistent performance for established recycling operations and manufacturing facilities.

Industrial Integration Systems

Large-scale solutions that connect seamlessly with conveyors, granulators, and automated sorting equipment. These systems handle massive volumes while maintaining precise particle size control.

Low Maintenance Design

Time is money in your business. Our simplified maintenance approach reduces downtime by 50%. Key components like blades and bearings remain easily accessible without full machine disassembly. The quick-change screen system allows rapid particle size adjustments, while the open-design chamber simplifies cleaning between different material types.

Exceptional Blade Longevity

Premium alloy construction delivers 3,000-5,000 operating hours before replacement becomes necessary. The blades support repeated sharpening (3-5 times), reducing replacement costs by 60% compared to standard carbon steel alternatives. This translates to substantial savings over the machine's lifetime.

Proven Reliability Standards

Precision bearings and hardened transmission gears ensure smooth operation with minimal vibration (≤0.1mm amplitude). This engineering excellence reduces mechanical wear and decreases failure rates by 40% compared to standard equipment. Regular lubrication systems maintain optimal performance throughout extended operating periods.

Cost-Effective Waste Processing

Transform your waste streams into revenue opportunities. Recycled materials can blend with new materials at 3:7 to 5:5 ratios, increasing raw material utilization by 30-50%. Many businesses save tens of thousands annually on material procurement costs while supporting environmental sustainability goals.

Complete Support Services

Ready to revolutionize your waste management processes? Contact our specialists at postmaster@xingbiaocrusher.com to discuss your specific requirements and discover how our Garbage shredder solutions can optimize your operations while reducing costs.

Learn about our latest products and discounts through SMS or email