Our crusher handles delicate movies, woven packs, difficult ABS plastics, thick channels, froth, and unpredictable shapes, killing the require for numerous machines and complex alterations, sparing cash and workspace.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

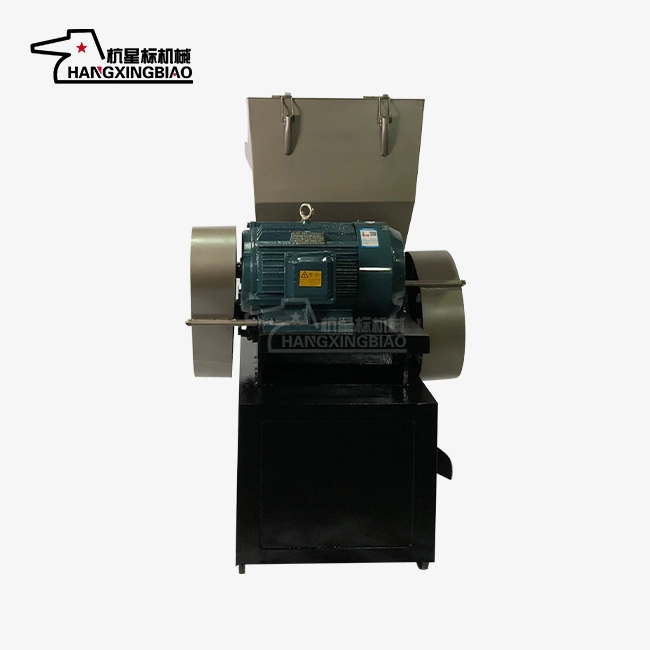

Powerful Crusher Machine

Transform Your Plastic Waste with Our Advanced Powerful Crusher Machine

Are you struggling with plastic waste disposal and recycling challenges in your facility? Our Powerful Crusher Machine delivers exceptional performance for both small-scale operations and large industrial applications. With preparing capacities extending from 50kg/h to 2000kg/h, this cutting-edge hardware changes squander into important reused materials productively. Whether you're running a little workshop or overseeing a expansive reusing plant, our crusher machines give the unwavering quality and productivity you require to maximize your plastic reusing operations.

Why Our Product Stands Out

Unmatched Material Compatibility

Superior Processing Efficiency

Our Powerful Crusher Machine delivers consistent performance with 15-20% higher efficiency than traditional equipment. Small models process 50-500kg per hour, while industrial models reach up to 2000kg/h capacity. Your operations run smoothly with 24-hour continuous operation capability.

The advanced design prevents material blockages and accumulation. You'll experience minimal downtime and maximum productivity throughout your workday.

Precise Particle Size Control

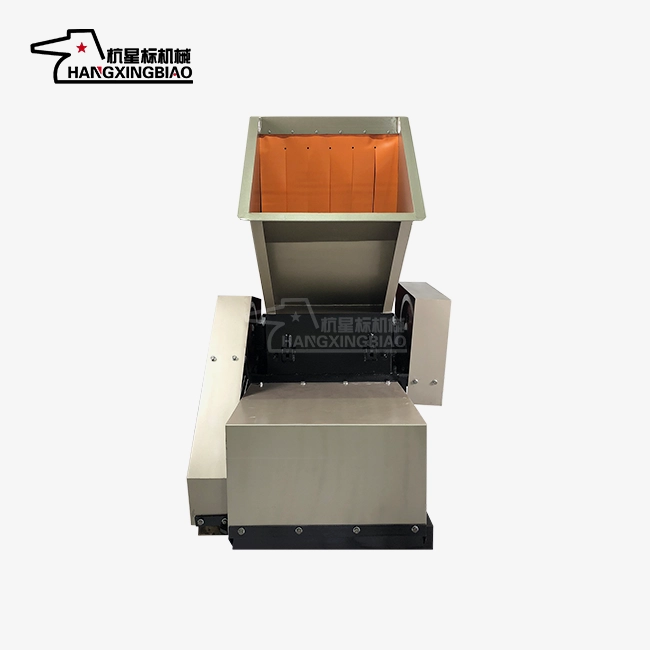

Adjustable screens (2–100 mm) allow precise particle size control for coarse pretreatment or fine granulation. Over 90% uniformity eliminates secondary screening, saving time and processing costs.

Exceptional Durability and Low Maintenance

Core cutting tools made from SKD11 and Cr12MoV steels (HRC 55–60) last 3,000–5,000 hours, resharpenable 3–5 times, cutting replacement costs 60% and minimizing production interruptions.

Advanced Safety and Environmental Features

Comprehensive Safety Protection

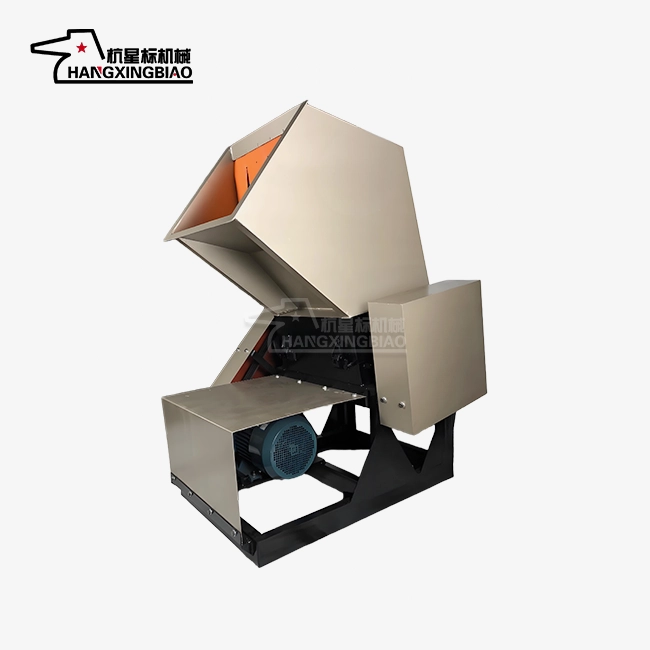

Thick steel chambers with anti-rebound baffles, external shields, and "open and stop" interlocks protect operators, prevent accidents, and ensure compliance with industrial safety standards.

Low Noise and Enclosed Design

Operating noise stays below 75 dB, and fully enclosed cavities prevent dust, keeping the workspace clean and meeting environmental standards while maintaining productivity.

Cost-Effective Operation Benefits

Immediate Waste Recycling

Transform your production waste into valuable raw materials instantly. Crush nozzle materials and waste scraps, then mix them with new materials at 3:7 or 5:5 ratios. This increases raw material utilization by 30-50%, saving thousands of dollars annually in material costs.

Energy Efficient Performance

Our optimized motor and transmission system in the Powerful Crusher Machine reduces energy consumption by 10–15% compared to traditional equipment. Processing one ton of plastic requires only 8–12 kWh of electricity, keeping your operating costs low.

Flexible Model Options for Every Need

We offer three main configurations:

Mobile Models: Compact units with universal wheels for flexible positioning between work stations. Perfect for smaller operations requiring mobility.

Fixed Models: Medium-sized floor-mounted units ideal for dedicated production lines. These provide stable, consistent performance for regular operations.

Integrated Models: Large-scale units that connect with granulators and conveyor systems for automated production lines. Suitable for high-volume recycling facilities.

Customization Available

Need specific requirements? We customize machines to match your exact processing needs. Our engineering team works with you to design the optimal solution for your facility.

Easy Maintenance and Cleaning

Simple body design allows quick cavity disassembly for thorough cleaning. This feature is especially valuable when switching between different colored plastics to prevent color contamination.

Key maintenance points remain accessible without full machine disassembly. Daily inspection and lubrication take minimal time, reducing maintenance requirements by 50%.

Proven Reliability and Performance

Ready to revolutionize your plastic waste management? Contact us at postmaster@xingbiaocrusher.com to discuss how our Powerful Crusher Machine can transform your operations. Our expert team provides personalized consultation to match the perfect solution to your specific requirements and processing goals.

Learn about our latest products and discounts through SMS or email