Our crushers use stress-relieved steel and SKD-11/D2/Cr12MoV blades treated with vacuum heat and cryogenics for high hardness, strong wear resistance, and extended service life.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

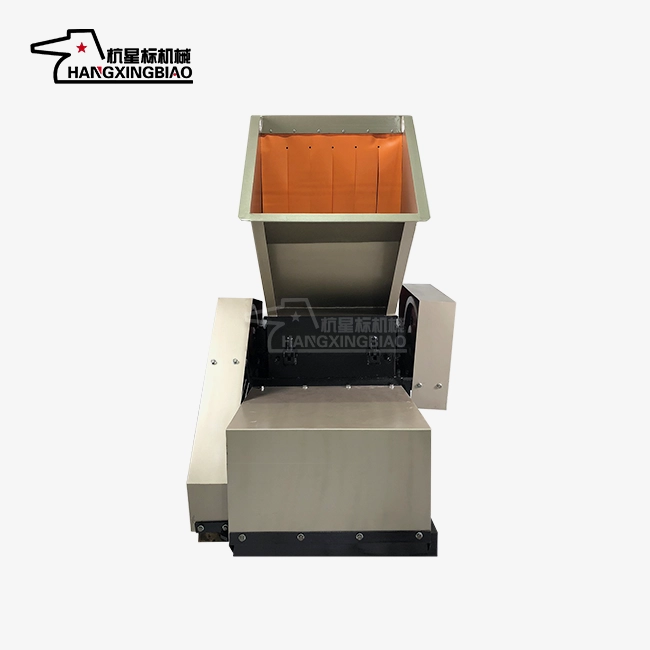

crusher machine for plastic

High-Performance Crusher Machine for Plastic - Professional Industrial Solutions

Are you struggling with plastic waste management in your production line? Looking for a reliable crusher machine for plastic that delivers consistent results? At Hangzhou Xingbiao Machinery Co., Ltd., we've spent 30 years perfecting industrial plastic crushing technology. Our advanced plastic crushers transform waste materials into valuable recycled resources, helping manufacturers reduce costs while maintaining high-quality output. Whether you're processing soft films or hard plastic components, our machines deliver the performance and reliability your operations demand.

Why Choose Our Plastic Crushing Solutions?

Unmatched Durability and Performance

Superior Crushing Efficiency

Our blade layout and cavity design raise efficiency over 20%, while the optimized motor reduces energy use, enabling faster processing, lower electricity costs, and improved profitability.

Wide Material Compatibility

Different projects require different approaches. Our product handles diverse material types with ease:

- Soft plastics: PE films, PVC sheets, woven bags, and textile fibers

- Hard plastics: ABS components, PC parts, thick-walled pipes, and profiles

- Foam materials: EPS packaging, EVA buffer foam, and insulation materials

- Irregular shapes: Plastic bottles, trays, mixed scraps, and die head materials

No need for frequent equipment changes or complex adjustments. One machine covers multiple crushing requirements across your facility.

Precise Particle Size Control

Our screening system offers 2–100 mm mesh options for adjustable output. Produce 5–50 mm fragments for pretreatment or 2–12 mm particles for granulation and molding. Particle uniformity exceeds 90%, removing the need for secondary screening.

Comprehensive Product Range

Heavy-Duty Industrial Models

Our heavy-duty crushers handle 1–10 tons per hour of large plastics and waste, delivering stable continuous performance with overload protection against metal contamination and hard materials.

Standard Production Units

Mid-range facilities benefit from our standard crusher machine for plastic models. Processing capacities range from 200-1000kg per hour, perfect for most manufacturing environments.

These units feature our signature low-noise design, operating at 75dB or below. The fully enclosed cavity prevents dust leakage while maintaining operator safety standards.

Compact Laboratory Models

Our compact models process 50–500 kg per hour with the same quality as larger units. Mobile designs with universal wheels allow flexible positioning and easy movement between production stations for research or small-batch needs.

Advanced Safety Features

Worker safety remains our top priority. Every unit includes comprehensive protection systems:

- Fully enclosed crushing chamber with reinforced steel construction

- Anti-rebound baffles at feed inlets prevent material ejection

- Safety shields around external components block potential hazards

- Interlocking systems automatically cut power when chambers open

These features create multiple protection layers, significantly reducing workplace injury risks.

Cost-Effective Operation

Smart manufacturing means controlling operational expenses. Our crushers deliver exceptional value through:

Reduced Raw Material Costs

Immediately recycle production waste like sprues, runners, and reject parts. Mix crushed materials with virgin plastic at 30-50% ratios. This recycling capability saves thousands in raw material purchases annually.

Lower Energy Consumption

Efficient motor design and optimized transmission systems reduce power usage by 10-15%. Processing one ton of plastic requires only 8-12 kWh of electricity.

Extended Tool Life

Premium alloy cutting tools last 3000-5000 hours under normal conditions. Tools support 3-5 resharpening cycles, reducing replacement costs by 60% compared to standard carbon steel alternatives.

Easy Maintenance Design

Quick-removal side panels simplify cavity cleaning when switching materials or colors. Key maintenance points stay accessible without full disassembly, and clearly marked lubrication points streamline servicing. Overall maintenance time is reduced by 50% compared to conventional designs.

Professional Support Services

Ready to transform your plastic waste into valuable resources? Our crusher machine for plastic solutions deliver the reliability, efficiency, and safety your operations deserve. Contact our technical team at postmaster@xingbiaocrusher.com for personalized equipment recommendations and detailed specifications.

Learn about our latest products and discounts through SMS or email