Our machines handle all polypropylene forms—rigid containers, flexible films, and mixed PP waste—processing thin packaging and thick-walled parts smoothly without frequent adjustments.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

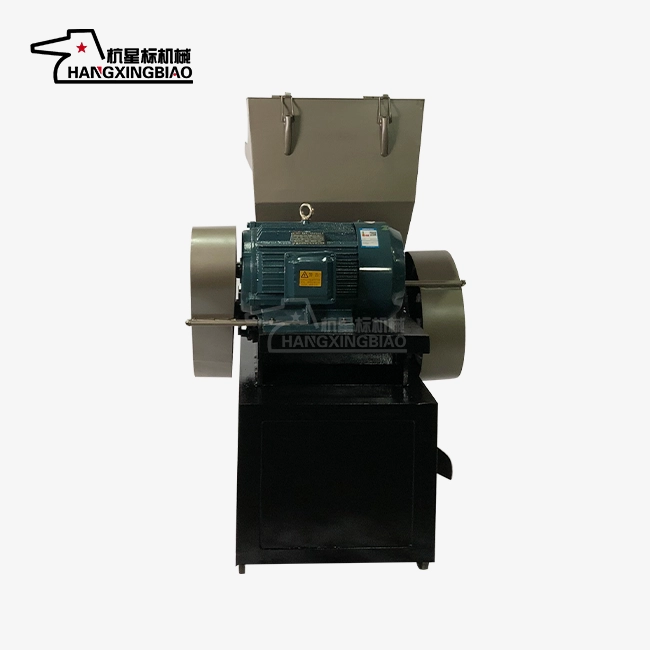

Polypropylene crusher

Polypropylene Crusher - Professional Plastic Recycling Solution

Are you looking for a reliable Polypropylene crusher to handle your plastic recycling needs? You're in the right put. At Hangzhou Xingbiao Apparatus, we specialize in high-performance smashing hardware planned particularly for polypropylene materials. Our progressed machines provide reliable molecule sizes extending from 2-20mm, making them idealize for reusing plants, fabricating offices, and handling operations. With over 30 a long time of centered mastery in plastic crusher improvement, we get it precisely what your trade needs to maximize proficiency and minimize costs.

Why Our PP Crushing Equipment Stands Out

Superior Material Compatibility

Exceptional Processing Efficiency

You’ll achieve 50 kg/h to 10 t/h throughput, with optimized blades and chamber design boosting efficiency by over 20%, processing more material in less time to improve profitability.

Precise Particle Control

Control your output size with interchangeable screens ranging from 2-100mm openings. This flexibility lets you produce coarse fragments for preliminary processing or fine particles ready for direct remelting. Our Polypropylene crusher delivers over 90% particle uniformity, eliminating the need for secondary screening.

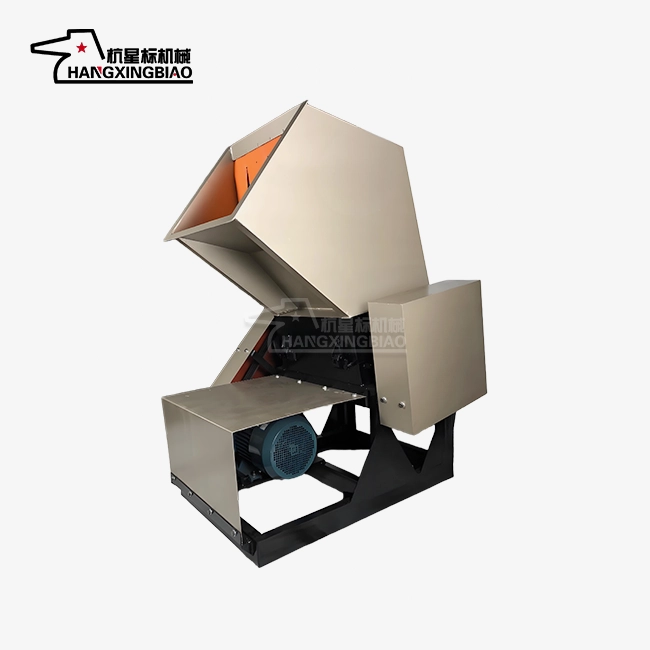

Built for Durability and Long-Term Performance

Advanced Blade Technology

Premium SKD-11 and Cr12MoV blades, heat-treated to HRC55–60, deliver 3,000–5,000 hours of life and 3–5 resharpening cycles, cutting blade replacement costs by 60%.

Robust Construction

The main frame uses high-strength steel plates with stress-relief welding. This prevents deformation during continuous operation. Our precision-balanced rotors minimize vibration to under 0.1mm, ensuring smooth operation and extending component life.

Energy-Efficient Operation

Smart engine coordinating and optimized transmission plan decrease control utilization by 10-15%. Preparing one ton of polypropylene regularly requires as it were 8-12 kWh, keeping your working costs moo whereas keeping up tall throughput.

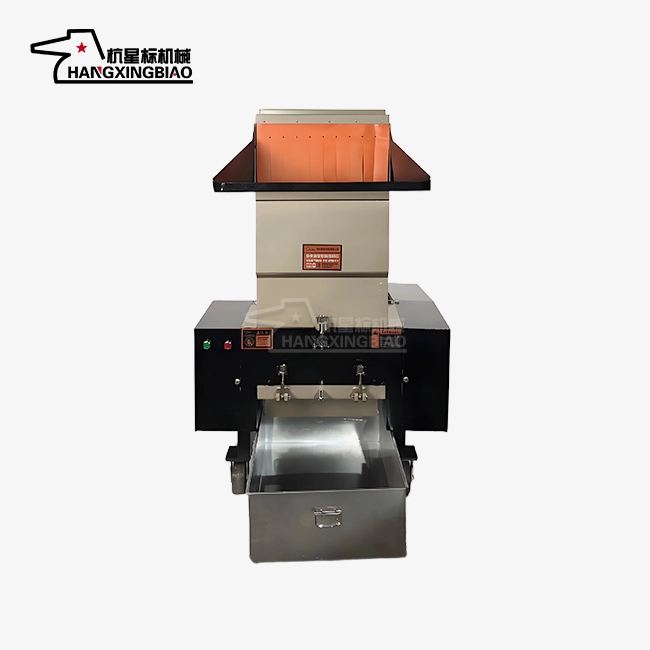

Safety and Maintenance Features

Comprehensive Safety Protection

Your operators stay protected with fully enclosed crushing chambers and anti-rebound baffles. Safety interlocks automatically cut power when access doors open, preventing accidents. External safety shields block any material splash during operation.

Easy Maintenance Access

The quick-change screen system and open chamber simplify cleaning and maintenance. Easily accessible blades and bearings cut maintenance time by 50% and reduce production downtime.

Versatile Applications for Your Business

Manufacturing Waste Recovery

Immediately recycle production scraps, runners, and rejected parts with the Polypropylene crusher. The crushed material blends with virgin polypropylene at ratios up to 50%, significantly reducing raw material costs. Many customers save thousands annually through efficient scrap recovery.

Commercial Recycling Operations

Process mixed polypropylene waste from various sources. The wide feed opening accepts bottles, containers, automotive parts, and packaging materials. Consistent output quality ensures your recycled material meets buyer specifications.

Custom Solutions Available

We offer mobile units, fixed installations, and integrated systems with conveyors and granulators. Our engineering team tailors configurations to your specific needs and space requirements.

Proven Reliability You Can Trust

With 20 senior engineers and 30 years of specialization, our designs meet real industrial demands. Partnerships with major companies guide development, while strict quality control and dynamic balancing deliver 40% lower failure rates than standard crushers.

Technical Support and Service

Our comprehensive benefit covers determination direction, establishment back, and administrator preparing. We react to all request inside 24 hours and keep up satisfactory save parts stock for speedy conveyance. Customary follow-up visits guarantee your gear proceeds working at top execution.

Get Started Today

For detailed specifications, pricing, or technical consultation, contact our experts at postmaster@xingbiaocrusher.com. Let us help you improve efficiency while reducing material costs through effective Polypropylene crusher polypropylene recycling.

Learn about our latest products and discounts through SMS or email