Our optimized blade layout and cavity design raise efficiency 20%, process 50–500kg or 1–10 tons hourly, and cut energy use 10–15%, reducing time loss and operating costs.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

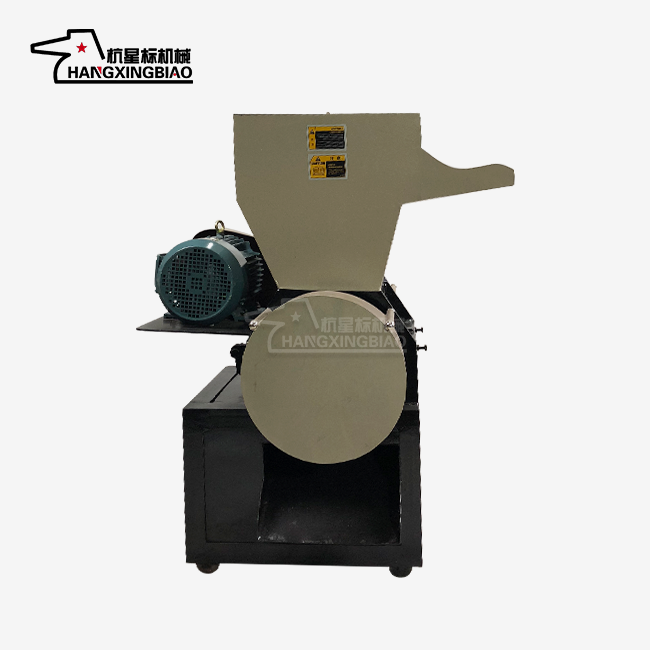

Industrial crusher

Industrial Crusher: Complete Material Processing Solutions for Your Business

Are you looking for reliable equipment to process waste materials efficiently? Our Industrial crusher technology delivers exceptional performance for businesses dealing with plastic recycling, waste management, and material processing operations. At Hangzhou Xingbiao Machinery Co., Ltd., we've dedicated 30 years to perfecting crusher design and manufacturing. Our specialized focus on single-category excellence means you get proven expertise and battle-tested equipment that handles diverse materials with confidence.

Why Choose Our Crushing Equipment?

Versatile Material Processing Capabilities

Your business handles diverse materials, and our crushers process plastics, rubber, wood, paper, cloth, foam, and non-corrosive chemicals, delivering consistent 2mm+ results for blocks, flakes, fibers, and irregular shapes.

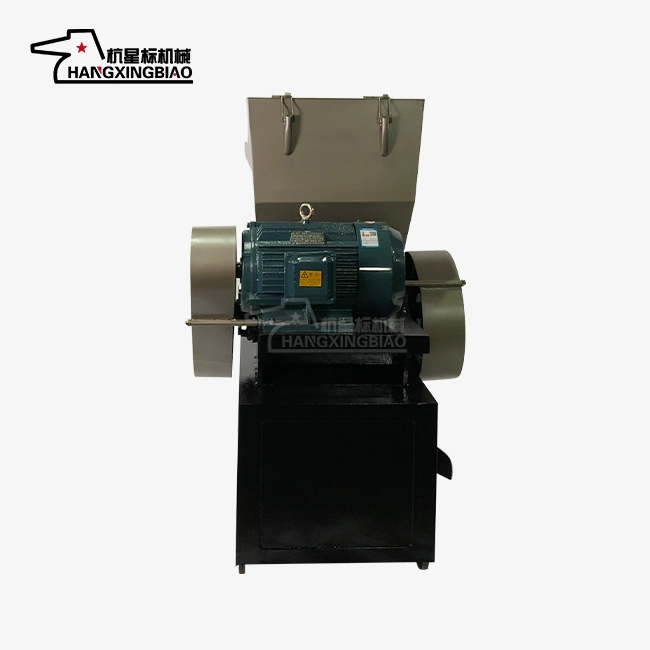

Superior Build Quality and Durability

We minimize downtime with high-strength construction and SKD-11/D2 and Cr12MoV blades treated by vacuum and cryogenic processes, ensuring long wear life and 3,000–5,000 hours of reliable operation.

Impressive Processing Efficiency

Complete Product Range for Every Application

Heavy-Duty Large-Diameter Models

Perfect for processing large plastic parts, pipes, profiles, and die head materials. These robust machines handle the toughest jobs with ease.

High-Power Centralized Feeding Systems

Low-noise operation makes these ideal for simultaneous sprue material recycling on injection molding machines. Your production floor stays quieter while maintaining efficiency.

Specialized Soft Material Processing

Designed specifically for films, woven bags, and fibers. These Industrial crusher models solve entanglement problems that plague standard equipment.

Custom Solutions

We create tailored solutions for unique challenges. Whether you're processing large-volume waste or highly entangled materials like trash cans and tires, we'll design equipment that meets your specific needs.

Flexible Output Control

You need consistent particle sizes for your downstream processes. Our screening system offers 2-100mm mesh options. Simply change screens to produce coarse fragments (5-50mm) for pretreatment or medium particles (2-12mm) for granulation and injection recycling. Particle uniformity exceeds 90%, eliminating secondary screening requirements.

Smart Design Features

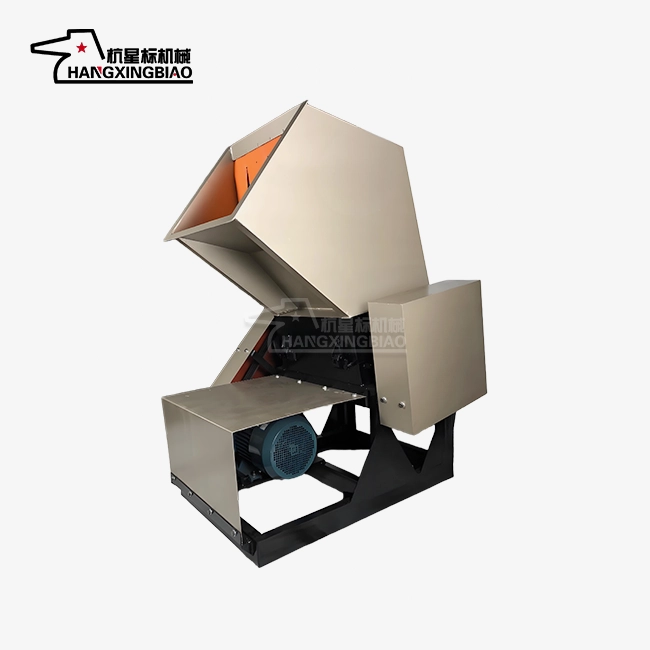

Safety First Approach

Our enclosed steel chambers, anti-rebound baffles, safety shields, and optional open-and-stop interlocks prevent kickback, block splashes, and cut power automatically to protect your team.

Easy Maintenance Access

Our simple design enables fast cavity cleaning and easy access to tools and bearings, cutting maintenance time by 50% and minimizing production loss.

Cost-Effective Operation

Blade longevity significantly impacts your bottom line. Our alloy steel construction with HRC55-60 hardness delivers exceptional durability. Blades support 3-5 regrinds, reducing replacement costs by 60% versus standard carbon steel alternatives. Processing one ton of plastic consumes just 8-12 kWh.

Immediate ROI Through Material Recycling

Recycle scrap instantly for profit by crushing nozzle waste for 3:7–5:5 reuse, raising material utilization 30–50% and cutting costs. Backed by 30 years of development, precision bearings, hardened gears, and balance testing ensure stable, low-vibration performance, reducing failure rates by 40% compared to standard models.

Professional Support Throughout Ownership

Our 20-person engineering team provides comprehensive support from selection through operation. We respond to inquiries within 24 hours and offer installation guidance, operation training, and regular follow-up visits. Sufficient spare parts inventory ensures minimal downtime when service needs arise.

Contact Us

Ready to transform your material processing operation with an Industrial crusher?Contact our engineering team at postmaster@xingbiaocrusher.com for personalized equipment recommendations and solutions tailored to your specific requirements.

Learn about our latest products and discounts through SMS or email