Our blade layout and cavity design boost crushing efficiency by over 20%, while optimized motor matching cuts energy use by 10–15%. Processing capacity spans 50 kg/h to 10 t/h, and all models support stable 24-hour continuous operation for smooth production.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

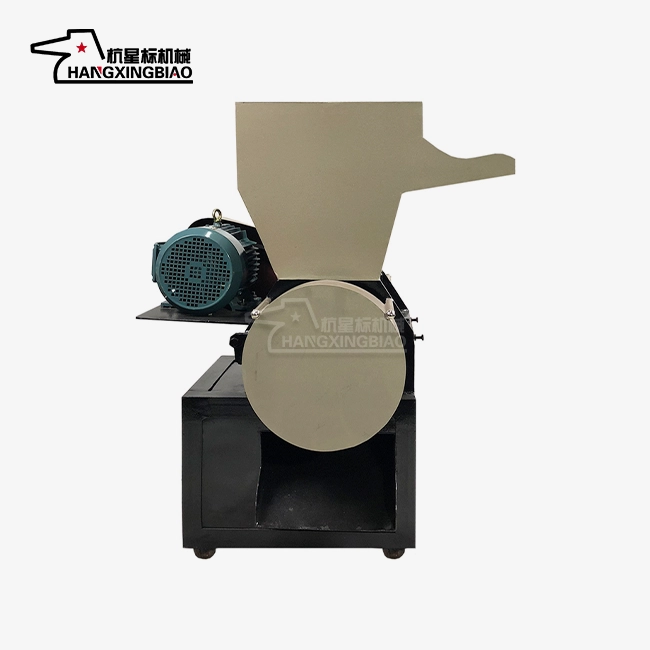

Industrial Crushers

Industrial Crushers - Professional Plastic Crushing Solutions

Looking for reliable Industrial Crushers that deliver exceptional performance? You've found the right partner. Hangzhou Xingbiao Machinery Co., Ltd. brings you 30 years of specialized expertise in plastic crushing technology. Our products are engineered to transform waste materials into valuable resources, helping your business reduce costs while maintaining superior quality standards. With proven track record serving diverse industries, we understand exactly what you need for efficient material processing.

Why Choose Our Plastic Crushing Equipment?

Exceptional Build Quality That Lasts

Our crushers use high-strength, stress-relieved welded steel bodies to prevent deformation during long-term operation. Blades made from SKD-11/D2 and Cr12MoV receive vacuum heat and cryogenic treatment, achieving HRC55-60 hardness and 3000–5000 hours of service life.

Superior Processing Efficiency

Wide Material Compatibility

Every material presents unique challenges. Our crushing systems handle diverse plastic types effortlessly:

- Soft plastics: PE/PVC films, woven bags, and flexible materials

- Hard plastics: ABS/PC parts, thick-walled pipes, and rigid components

- Foam materials: EPS/EVA buffer foam and lightweight plastics

- Irregular shapes: Plastic bottles, trays, and mixed scraps

No frequent equipment changes needed. One machine covers multiple crushing requirements across your facility.

Precise Particle Size Control

Our screening system provides 2–100 mm particle options by simply changing the mesh. Produce 5–50 mm fragments or 2–12 mm fine particles with over 90% uniformity, eliminating the need for secondary screening.

Comprehensive Product Range

Heavy-Duty Large-Diameter Models

Perfect for processing large plastic parts, pipes, profiles, and die head materials. These robust units handle the toughest crushing challenges in your facility.

High-Power Centralized Feeding Systems

Designed for quiet operation alongside injection molding machines. These Industrial Crushers efficiently recycle sprue material without disrupting your production environment.

Standard Film Processing Units

Specially engineered for soft plastics like films, woven bags, and fibers. Our anti-entanglement design solves common processing headaches.

Custom Solutions

Processing unusual materials like large trash cans or tire components? We engineer custom crushing solutions tailored to your specific requirements.

Safety and Environmental Features

Our enclosed design uses thick steel plates, anti-rebound baffles, and safety shields. Select models include interlocking systems that cut power when opened. Precision bearings and hardened gears keep vibration ≤0.1 mm, reducing loosening and lowering failure rates by 40%.

Easy Maintenance and Operation

Our quick-change screen and open design cut maintenance time by 50%, with key parts accessible without full disassembly. The simple structure enables fast cavity cleaning to prevent color contamination, while blades support 3–5 regrinds, reducing replacement costs by 60%.

Cost-Effective Recycling Solutions

Transform waste into profit streams. Crushed materials mix directly with virgin materials at 3:7 to 5:5 ratios in your production process. This increases raw material utilization by 30%-50%.

The immediate recycling capability saves thousands in raw material costs annually. Processing one ton of plastic requires only 8-12 kWh of electricity.

Three Decades of Specialized Expertise

Our 20-member engineering team brings deep industry knowledge to every project. We've established research partnerships with major companies, continuously advancing crushing technology.

This focused approach means you get equipment designed specifically for crushing applications, not generic industrial machinery adapted for your needs.

Professional Support Every Step

Ready to transform your material processing efficiency? Contact our expert team at postmaster@xingbiaocrusher.com today. Let's discuss how our Industrial Crushers can optimize your operations and boost profitability.

Learn about our latest products and discounts through SMS or email