- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

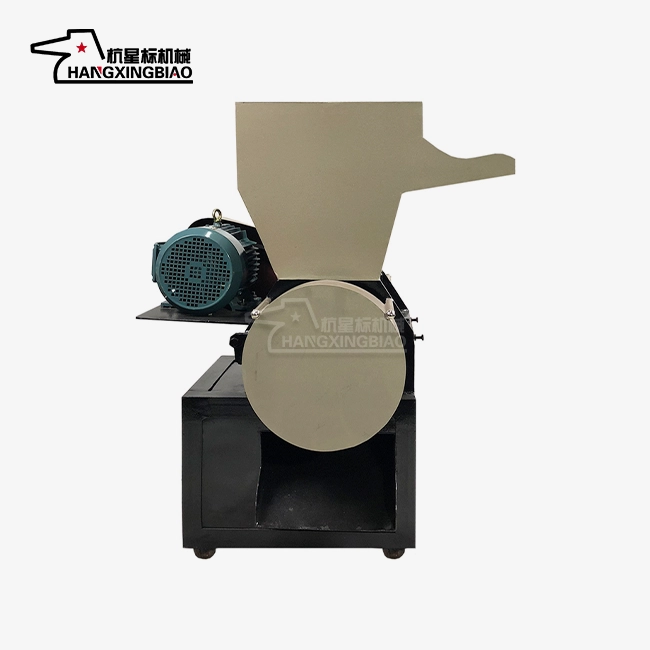

Plastic shredder

Professional Plastic Shredder for Industrial Recycling

Looking for a reliable plastic shredder to handle your recycling needs? You've come to the right place. At Hangzhou Xingbiao Machinery Co., Ltd., we've been perfecting our plastic shredding technology for over 30 years. Our machines break down different sorts of plastic squander into sensible pieces, making a difference you decrease costs and progress your reusing productivity. Whether you're handling film, bottles, or mechanical plastic scraps, our hardware conveys reliable comes about that meet your generation requests.

Why Our Products Stand Out

Built to Last, Built to Perform

Your production line needs equipment that won't let you down. Our machines feature high-strength steel construction with stress relief treatment. This means no warping or deformation, even after years of heavy use.

The cutting blades are crafted from premium materials like SKD-11 and Cr12MoV steel. These undergo vacuum heat treatment and cryogenic processing. The result? Hardness levels reaching HRC55-60 and blade life extending up to 5,000 hours.

Process Any Plastic Type

Why limit yourself to one material type? Our versatile machines handle:

- Soft plastics: PE films, PVC sheets, woven bags

- Hard plastics: ABS parts, PC components, thick pipes

- Foam materials: EPS packaging, EVA cushioning

- Mixed waste: Bottles, containers, production scraps

You won't need multiple machines for different materials. One unit covers all your shredding requirements.

Particle Size Control

Different applications need different output sizes. Our interchangeable screens let you produce exactly what you need:

- Coarse fragments (5-50mm) for preliminary processing

- Medium particles (2-12mm) for granulation

- Custom sizes from 2-100mm range

Over 90% particle uniformity means no secondary screening needed.

Efficiency That Impacts Your Bottom Line

Immediate Cost Savings

Turn your waste into profit instantly. Our plastic shredder processes production scraps, runner materials, and defective parts on-site. You can blend the shredded material with virgin plastic at ratios up to 50:50.

This recycling approach increases your raw material utilization by 30-50%. Many customers save tens of thousands in material costs annually.

Energy Efficient Operation

Our optimized motor and transmission design reduces power consumption by 10-15% compared to conventional shredders. Processing one ton of plastic typically uses just 8-12 kWh of electricity.

Small models handle 50-500kg per hour. Industrial units process up to 10 tons hourly. All models support continuous 24-hour operation.

Safety and Reliability Features

Protection You Can Trust

Your team's safety comes first. Every machine includes:

- Fully enclosed crushing chamber with thick steel walls

- Anti-rebound baffles at feed openings

- Safety interlocks that cut power when chambers open

- Protective shields blocking material splash

Low Maintenance Design

We know downtime costs money. That's why our machines feature:

- Quick-release chamber access for easy cleaning

- Exposed maintenance points for simple inspection

- Precision bearings with regular lubrication systems

- Dynamic balance testing reducing vibration to ≤0.1mm

Equipment failure rates drop by 40% compared to standard models. Maintenance time decreases by 50%.

Choose Your Perfect Model

Flexible Options for Every Need

Mobile Units: Compact designs with wheels for moving between workstations. Perfect for smaller operations or multi-location processing.

Fixed Installation: Medium-capacity machines for dedicated production lines. Stable performance for consistent daily operations.

Integrated Systems: Large-scale units that connect with conveyors and granulators. Complete automation for high-volume facilities.

From laboratory testing (50kg/h) to industrial recycling (10t/h), we have the right size for your operation.

Proven Technology, Trusted Results

Ready to transform your plastic waste management? Contact our team at postmaster@xingbiaocrusher.com for personalized equipment recommendations. We'll help you select the perfect plastic shredder for your specific needs and provide complete installation support.

Learn about our latest products and discounts through SMS or email