Your crushers use stress-relieved high-strength steel and SKD-11/D2 blades with heat and cryogenic treatment, ensuring no deformation and 3000–5000 hours of reliable crushing.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

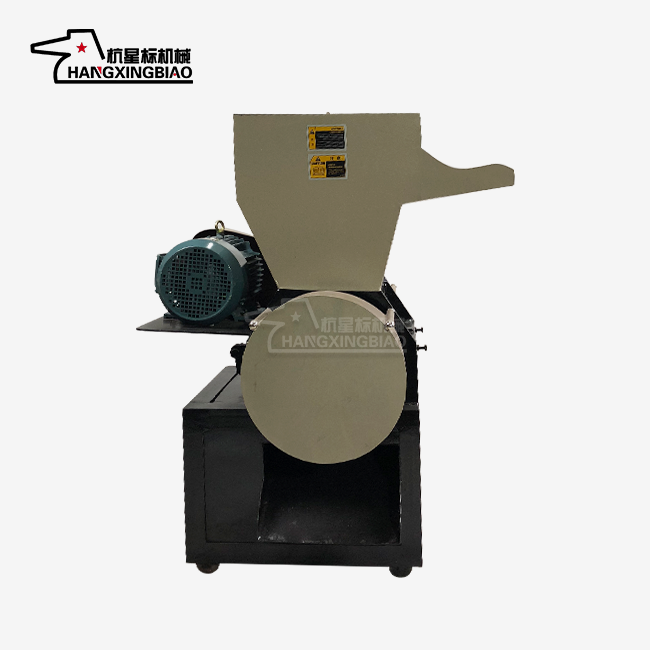

Automatic plastic bottle crusher

Automatic Plastic Bottle Crusher: Efficient Recycling Solution for Your Business

Are you struggling with plastic bottle waste management? Our automatic plastic bottle crusher delivers exceptional performance for recycling facilities, manufacturing plants, and waste processing centers. Designed by Hangzhou Xingbiao Machinery Co., Ltd., this advanced crushing system transforms plastic bottles into uniform particles efficiently. With 30 years of specialization in plastic crushing technology, we've engineered equipment that maximizes your recycling potential while minimizing operational costs. Our crusher handles various bottle types seamlessly, from PET beverage containers to HDPE milk jugs.

Why Choose Our Plastic Bottle Crushing Solution?

Superior Build Quality

Exceptional Processing Capacity

Our machines handle 50kg–10 tons/hour, with blade and chamber designs boosting efficiency 20%. Interchangeable meshes ensure consistent 2–50 mm particle sizes.

Energy-Efficient Operation

Smart motor optimization reduces energy consumption by 10-15% versus conventional crushers. Processing one ton of plastic bottles requires only 8-12 kilowatt-hours of electricity. This efficiency translates into significant cost savings for your facility.

Advanced Features for Maximum Performance

Wide Material Compatibility

Handle diverse plastic bottle types without equipment modifications. Our automatic plastic bottle crusher processes soft PE bottles, rigid PET containers, foam packaging, and irregular-shaped containers. This versatility eliminates the need for multiple crushing systems.

Precision Particle Control

Achieve over 90% particle uniformity with interchangeable 2–100 mm meshes, allowing coarse or fine outputs for any application while ensuring consistently reliable results.

Safety-First Design

Fully enclosed chambers prevent splash, while anti-rebound baffles stop kickback. Select models use interlock systems that cut power when opened to prevent accidental injuries.

Cost-Effective Recycling Benefits

Immediate Scrap Recovery

Transform production waste into valuable raw material instantly. Crushed plastic can blend with virgin material at ratios of 30-50%, increasing material utilization dramatically. This recycling capability saves thousands in annual raw material costs.

Reduced Maintenance Expenses

Durable alloy steel tools allow 3–5 re-sharpenings, cutting replacement costs by 60%. Precision bearings and hardened gears reduce wear and lower failure rates by 40%.

Quick Maintenance Access

Simple body construction allows rapid chamber disassembly for cleaning. Key maintenance points remain easily accessible without full machine teardown. This design cuts maintenance time in half while ensuring thorough cleaning between different plastic types.

Flexible Model Options

Mobile Units

Compact crushers with universal wheels provide workstation flexibility. Perfect for smaller operations requiring portability between different processing areas.

Fixed Installation Systems

Medium-capacity units designed for permanent production line integration. These models offer enhanced stability for continuous operation environments.

Automated Production Lines

Large-scale systems integrate seamlessly with conveyors and granulators. Create complete automated recycling workflows from bottle input to finished pellet output.

Professional Engineering Support

Our team of 20 senior engineers provides comprehensive technical assistance. We've established successful partnerships with industry leaders like Nongfu Spring and KFC, proving our expertise in real-world applications.

Complete Service Package

- Pre-sales consultation and system design

- Installation guidance and operator training

- 24-hour response guarantee for technical support

- Regular maintenance follow-ups

- Comprehensive spare parts inventory

Customization Capabilities

Every facility has unique requirements. We design custom solutions for special applications, unusual bottle types, or specific output requirements. Our engineering team works directly with you to optimize crusher configuration for maximum efficiency.

Technical Specifications

Your product maintains minimal vibration through balanced components and precision-lubricated bearings. Temperature-resistant chambers prevent overheating during continuous use, while sound-dampening design reduces noise for sensitive environments.

Ready to Transform Your Plastic Waste Management?

Transform plastic bottle waste into profit with our Automatic plastic bottle crusher and proven crushing technology.Contact our engineering team at postmaster@xingbiaocrusher.com to discuss your specific requirements and receive a customized solution proposal for your facility.

Learn about our latest products and discounts through SMS or email