Our systems use stress-relieved steel for structural integrity, with SKD-11/D2 blades treated by vacuum heat and cryogenic processes. With HRC55–60 hardness, blades last 3000–5000 hours and can be reground up to five times, reducing replacement costs by 60%.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

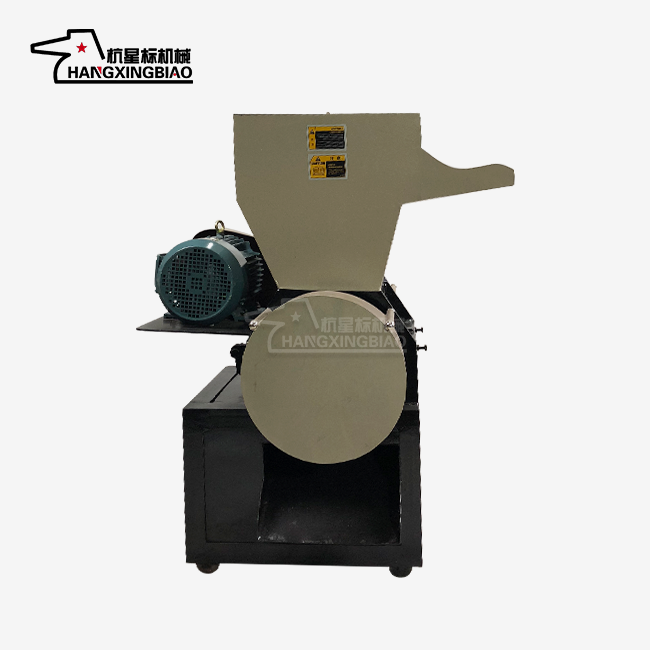

glass crushing machine

Professional Glass Crushing Machine - High-Performance Solutions for Your Glass Recycling Needs

When you're looking for reliable glass processing equipment, choosing the right glass crushing machine makes all the difference in your operation's efficiency and profitability. Our progressed pulverizing frameworks are designed to handle different sorts of glass materials with extraordinary execution. Whether you handle bottles, sheets, or mechanical glass squander, our apparatus conveys steady comes about that surpass industry measures. With over 30 a long time of specialized encounter, we get it your special challenges and give arrangements that maximize efficiency whereas minimizing operational costs.

Why Choose Our Advanced Glass Processing Equipment?

Unmatched Engineering Excellence

Superior Processing Capabilities

Our equipment handles all glass types without adjustments, offering 50–500 kg/hour to 1–10 tons/hour capacity and supporting 24-hour continuous operation.

Precision Output Control

Achieve precise particle sizes through interchangeable screening systems. Options range from 2-100mm, allowing you to produce coarse fragments for preliminary processing or fine particles for recycling applications. Particle uniformity exceeds 90%, eliminating secondary screening requirements.

Advanced Design Features

Energy-Efficient Operation

Optimized motors and transmission reduce energy use by 10–15%, needing only 8–12 kWh per ton. Efficient blade layout and cavity design boost crushing efficiency by over 20%, increasing productivity and reducing processing time.

Comprehensive Safety Systems

Your team's safety is paramount. Each glass crushing machine features fully enclosed safety protection with thick steel plate construction. Anti-rebound baffles at feed inlets prevent material ejection, while external safety shields block debris during operation.

Select models include interlocking devices that automatically cut power when chambers are opened, preventing accidental injury during maintenance or cleaning.

Minimal Maintenance Requirements

Precision bearings, hardened gears, and regular lubrication minimize wear, while dynamic balance keeps vibration under 0.1 mm. Accessible maintenance points cut service time by 50%.

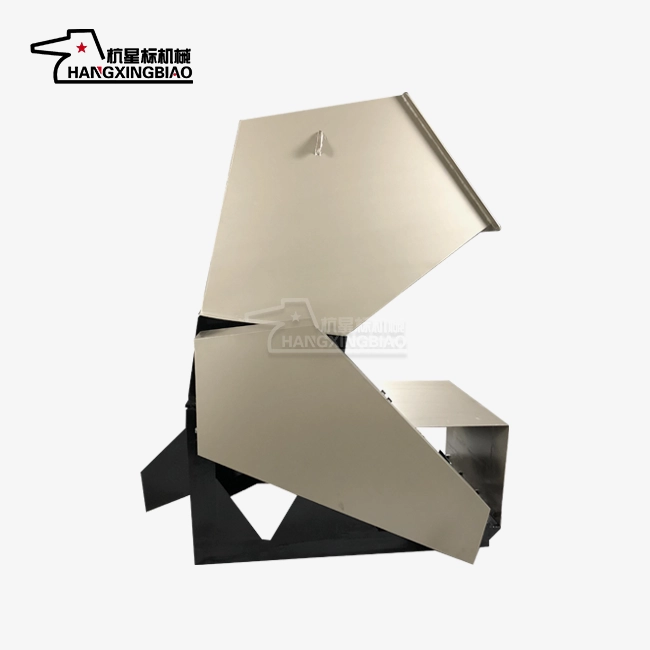

Flexible Configuration Options

Multiple Model Categories

Choose from three primary configurations to match your operational needs:

Mobile Units: Compact systems with universal wheels for flexible positioning across different work stations. Perfect for smaller operations requiring equipment mobility.

Fixed Installation: Medium-capacity floor-mounted units ideal for dedicated production lines. These systems provide stable, consistent performance for regular processing requirements.

Integrated Systems: Large-capacity units designed for automated production lines. Compatible with conveyors and other processing equipment for complete workflow integration.

Customization Capabilities

Our engineering team creates customized solutions for unique processing challenges. Whether you handle specialized glass types or require specific output characteristics, we develop equipment tailored to your exact specifications.

Proven Reliability and Support

Comprehensive Service Network

Our engineering team supports you through the entire equipment lifecycle, from consultation to installation and maintenance. We respond within 24 hours, providing training, guidance, and follow-up to keep your equipment running at peak performance.

Quality Assurance

Every glass crushing machine undergoes rigorous testing before delivery. Our quality control processes ensure consistent performance and reliability. The robust construction and premium components deliver dependable operation for years of service.

Sufficient save parts stock guarantees negligible delays when substitution components are required. This comprehensive parts back keeps your gear running easily with diminished downtime.

Industry-Leading Technology

Our 20-member building group drives persistent advancement through college and producer organizations. One of a kind edge geometry and chamber plan boost effectiveness, decrease wear, and convey lower working costs with longer gear life.

Contact Us Today

Ready to improve your glass processing operations with our advanced glass crushing machine solutions? Contact our team at postmaster@xingbiaocrusher.com for personalized consultation and equipment recommendations tailored to your specific requirements.

Learn about our latest products and discounts through SMS or email