Our machine offers flexible particle control with interchangeable 2–100 mm screens. Output uniformity exceeds 90%, removing the need for secondary screening and saving time by reducing processing steps.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

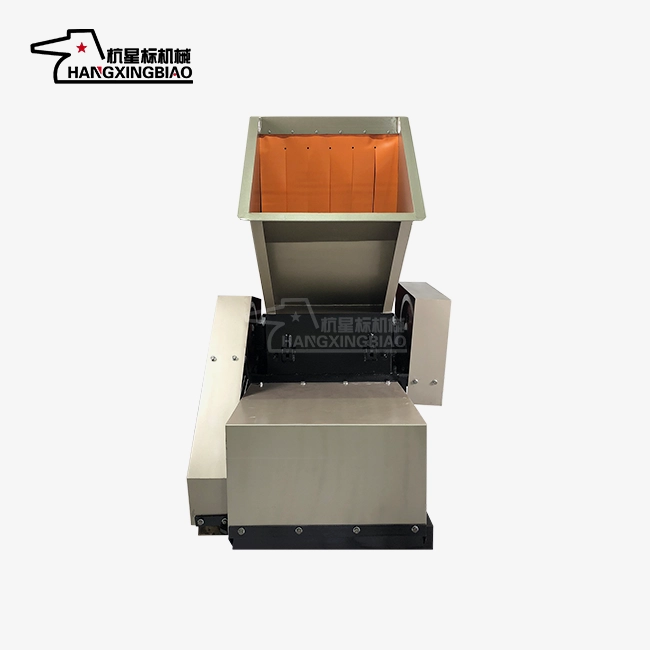

wood crusher machine

Wood Crusher Machine - Professional Grinding Solutions for Multiple Materials

Are you looking for an efficient solution to process various materials into uniform particles? Our professional wood crusher machine delivers exceptional performance for wood, plastic, and other materials. Designed for reliability and versatility, this crusher transforms large pieces into manageable 2-20mm particles, making transportation and storage more convenient. Whether you're in recycling, manufacturing, or agricultural processing, our machine helps you achieve consistent results while reducing operational costs.

Why Choose Our Crushing Equipment?

Superior Material Compatibility

Our crushing equipment handles diverse materials with ease. From hardwood branches to plastic components, the machine processes everything efficiently. You'll appreciate how it manages both hard and soft materials without frequent adjustments.

The versatile design accommodates:

- Wood chips and branches

- Plastic bottles and containers

- Cardboard and packaging materials

- Agricultural waste like corn stalks

Exceptional Processing Efficiency

Our equipment delivers strong throughput: small models process 50–500 kg/h, industrial units 1–10 tons, running 24/7 without interruption. An optimized blade layout boosts crushing efficiency by 20%, reducing blockages and ensuring smoother operation.

Precise Particle Size Control

Durable Construction and Low Maintenance

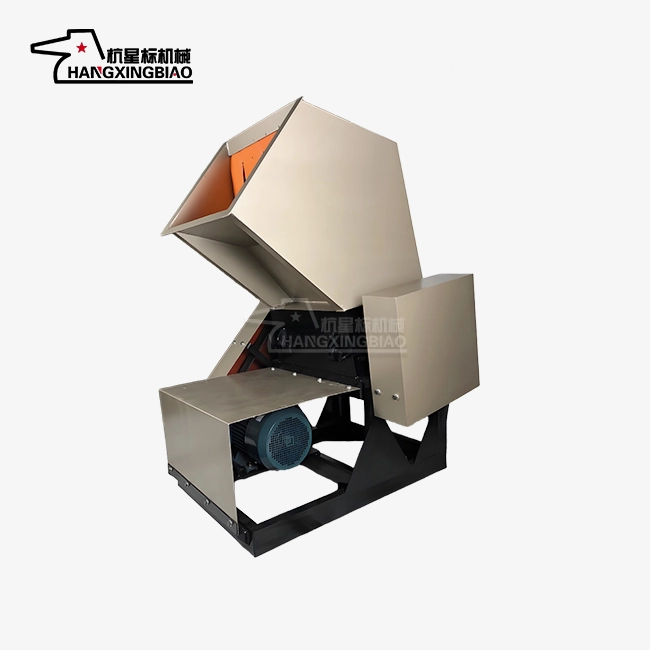

Our equipment uses high-strength welded steel with stress relief to prevent deformation. SKD-11 and Cr12MoV blades receive vacuum heat and cryogenic treatment, achieving HRC55–60 hardness and 3000–5000 hours of service life for long-term reliability.

Cost-Effective Operation

Energy Efficiency

Your operating costs stay manageable with our energy-efficient design. The optimized motor and transmission system reduce energy consumption by 10-15% compared to conventional equipment. Processing one ton of material typically requires only 8-12 kWh of electricity.

Tool Longevity and Reusability

The premium cutting tools support repeated sharpening. You can polish the blades 3-5 times before replacement. This reusability reduces tool costs by 60% compared to standard carbon steel alternatives.

Immediate Material Recovery

In manufacturing environments, you can instantly recycle production waste. Crushed materials blend with new materials at ratios of 30-50%. This recycling capability increases raw material utilization significantly, potentially saving thousands in procurement costs annually.

Safety and Reliability Features

Your team's safety comes first. That's why our wood crusher machine includes comprehensive protection systems. The crushing chamber features thick steel plate construction with anti-rebound shields at the feed inlet.

Selected models feature interlock systems that cut power when the chamber opens, preventing injuries. Hardened gears, quality bearings, and proper lubrication reduce wear. Dynamic balance testing keeps vibration under 0.1 mm, preventing loosening and lowering failure rates by 40%.

Flexible Configuration Options

Choose from three main configurations to match your needs:

Mobile Units: Compact designs with wheels for easy positioning between work stations.

Fixed Installation: Medium-capacity units for permanent production line integration.

Automated Systems: Large-capacity machines that integrate with conveyors and other processing equipment.

Easy Maintenance and Cleaning

Maintenance simplicity saves you valuable time. The accessible design allows quick cleaning when switching between different materials. Side panels remove easily for thorough chamber cleaning.

Key maintenance points remain exposed and accessible. Daily inspection and lubrication require no major disassembly. This design reduces maintenance time by 50% compared to complex alternatives.

Technical Excellence

Hangzhou Xingbiao Machinery brings three decades of focused expertise to crushing technology. Our 20-engineer development team continuously improves performance and reliability. We maintain industry partnerships that drive innovation in crushing solutions.

Quality control ensures every machine meets strict performance standards. Comprehensive testing validates durability and efficiency before delivery.

Complete Support Services

Ready to improve your material processing efficiency? Contact our team at postmaster@xingbiaocrusher.com for personalized consultation. We'll help you find the perfect wood crusher machine solution for your specific requirements and budget.

Learn about our latest products and discounts through SMS or email