The PET bottle crusher screen hole pattern also affects material flow through the crusher. Optimized patterns reduce blockages and improve throughput rates.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

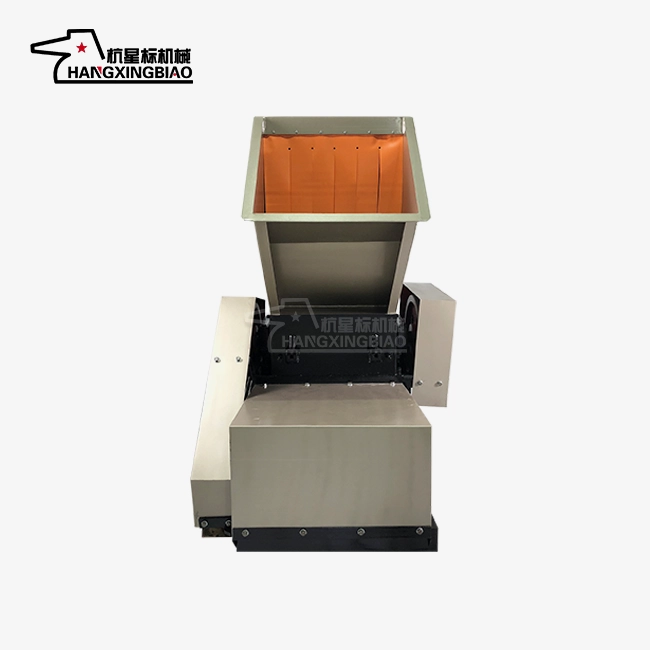

PET bottle crusher screen

PET Bottle Crusher Screen: Essential Component for Efficient Plastic Recycling

When choosing the right plastic recycling equipment, you'll find that a quality PET bottle crusher screen makes all the difference in your operation's success. This pivotal component decides your yield quality, molecule measure consistency, and generally smashing proficiency. Whether you're running a little reusing office or overseeing large-scale plastic squander preparing, understanding the significance of the appropriate screen choice will offer assistance you maximize your speculation and accomplish ideal results.

What Is a Product?

A crusher screen channels fabric by controlling molecule measure through absolutely built gaps. Distinctive work sizes make shifted yields: littler gaps abdicate fine particles for reprocessing, whereas bigger openings create coarser parts for encourage processing.

The screen's plan straightforwardly impacts your crusher's execution. A well-designed screen guarantees steady molecule estimate dispersion. It moreover anticipates sticking and diminishes wear on your equipment's cutting blades.

Key Highlights of Quality Crusher Screens

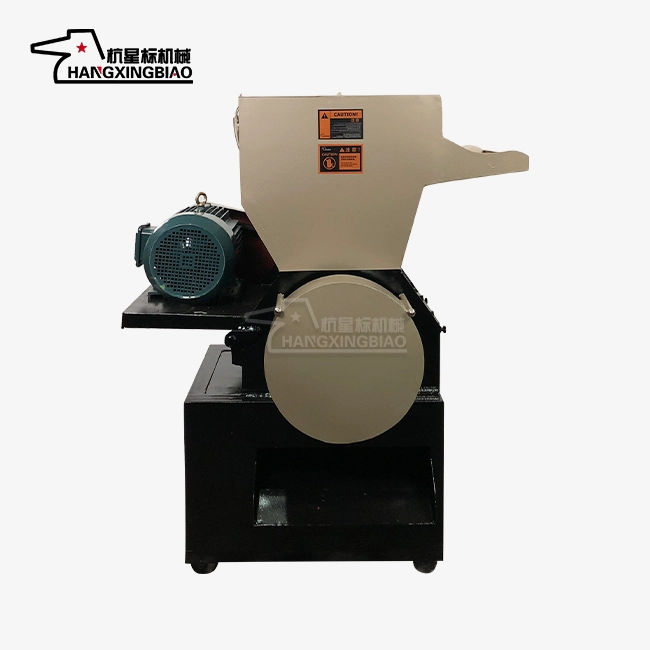

Durable Fabric Construction

Premium screens utilize high-strength steel combinations that stand up to wear and distortion. Extraordinary warm treatment boosts hardness and enormously amplifies benefit life, decreasing substitutions and upkeep costs.

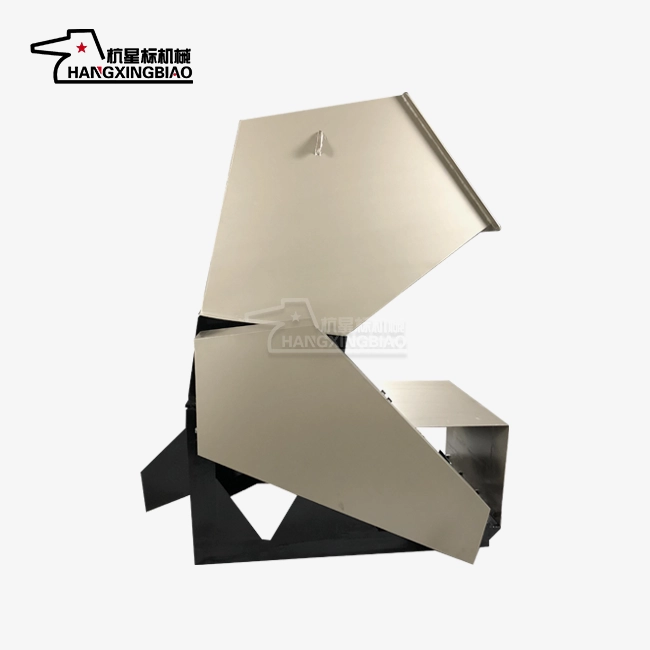

Precision Gap Patterns

Professional-grade screens include absolutely machined or punched gaps. These openings keep up steady measurements over the whole screen surface. Uniform gaps guarantee indeed molecule estimate dispersion in your last item.

Easy Installation Design

Quality screens incorporate quick-change mechanisms for fast replacement. This design minimizes downtime when switching between different particle sizes. Simple installation also reduces labor costs during maintenance periods.

Benefits of Using the Right Screen

Consistent Output Quality

The right screen delivers uniform PET particle size, improving recycled material quality and ensuring smoother downstream processing. Consistent particles reduce waste, enhance melting performance, and improve final product quality.

Enhanced Processing Efficiency

Properly sized screens maximize material flow and maintain output quality, boosting productivity and profitability. Efficient screening also lowers energy use per unit, improving overall operating economics.

Extended Equipment Life

Quality screens protect internal components by blocking oversized materials, reducing blade wear and extending equipment life. Proper screening also lowers motor and drive stress, resulting in fewer repairs and reduced maintenance costs.

Screen Size Selection Guidelines

Fine Particle Applications (2-5mm)

Use fine mesh screens for applications requiring small particle sizes. These screens work well for direct injection molding feedstock. They're also suitable for high-quality recycled pellet production.

Fine screens may require slower processing speeds to prevent blocking. Consider your throughput requirements when selecting fine mesh options.

Medium Particle Applications (5-12mm)

Medium mesh screens offer excellent versatility for most recycling applications. They provide good throughput while maintaining acceptable particle quality. These screens work well for general-purpose recycling operations.

The product hole pattern also affects material flow through the crusher. Optimized patterns of the PET bottle crusher screen reduce blockages and improve throughput rates.

Coarse Particle Applications (12-25mm)

Coarse screens boost throughput for initial size reduction, ideal for thick-walled bottles and containers. They ease downstream load, improving overall system efficiency and reducing wear.

Maintenance and Care Tips

Regular Inspection Schedule

Inspect screens weekly for wear, enlarged holes, or cracks to prevent quality issues and damage. Check mounting hardware for looseness or wear to ensure proper function and avoid vibration-related problems.

Proper Cleaning Procedures

Clean screens thoroughly when changing materials or colors to prevent contamination. Use suitable solvents and remove all debris from holes to maintain proper flow, efficiency, and even wear.

Replacement Timing

Replace screens proactively to maintain output quality and prevent component damage. Keep spare screens in stock to minimize downtime and ensure continuous operation.

Contact Us

Ready to improve your plastic recycling operation? Contact us at postmaster@xingbiaocrusher.com to discuss your specific PET bottle crusher screen requirements and find the perfect solution for your facility.

Learn about our latest products and discounts through SMS or email