For 30 years, Hangzhou Xingbiao Machinery has specialized in plastic crushers. Our 20 senior engineers collaborate with industry leaders to deliver innovative, expert solutions.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

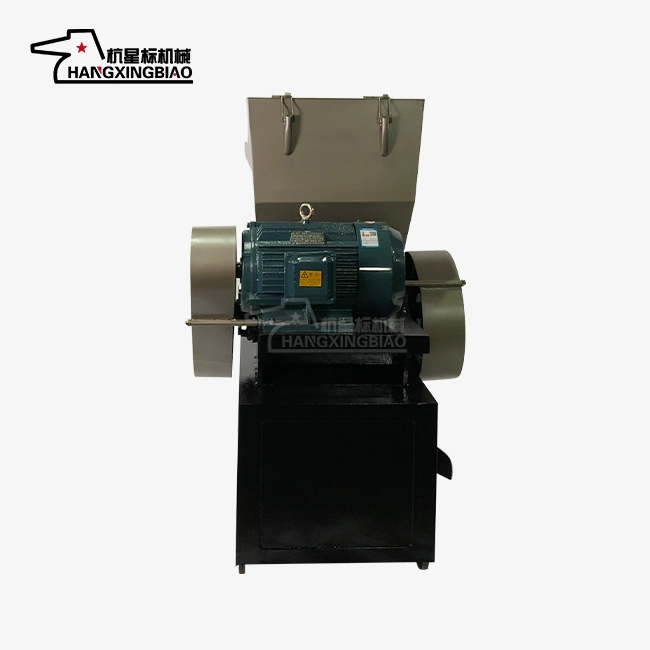

Small plastic shredder

Small Plastic Shredder: Professional Plastic Waste Processing Solution

When you need efficient plastic waste processing for your business, our Small plastic shredder delivers exceptional performance and reliability. Designed specifically for compact operations and diverse plastic materials, this machine combines advanced engineering with user-friendly operation. Whether you're running a small manufacturing facility or managing plastic recycling operations, our product provides the perfect balance of power, efficiency, and space-saving design to meet your needs.

Why Choose Our Plastic Shredding Equipment?

Proven Expertise You Can Trust

Superior Build Quality

Your investment deserves durable equipment. High-strength steel with stress relief prevents deformation. Core blades use SKD-11/D2 and Cr12MoV steels, treated with vacuum heat and cryogenic processing for maximum hardness and wear resistance.

Advanced Processing Technology

Dual-Action Crushing System

Our Small plastic shredder employs an innovative "shear + impact" dual-effect crushing process. This advanced system optimizes cavity structure and blade spacing for discharge requirements over 2mm. You avoid excessive crushing while maintaining material particle integrity with minimal powder contamination.

The discharge uniformity exceeds 90%, eliminating the need for secondary screening. This saves you time and reduces operational complexity.

Anti-Tangling Innovation

Our anti-winding comb tooth design handles films, fabrics, and fibers effortlessly, preventing jamming or tangling. This feature minimizes downtime and reduces maintenance needs significantly.

Exceptional Performance Specifications

Versatile Material Compatibility

Process diverse plastics without modification—soft PE/PVC films, woven bags, hard ABS/PC parts, thick-walled pipes, EPS/EVA foam, and irregular shapes like bottles and trays—all handled efficiently.

Precise Particle Control

Select 2-100mm screens and adjust blade speed or cutting sets to achieve exact output—coarse fragments (5-50mm) for pretreatment or medium particles (2-12mm) for granulation and injection recycling.

Outstanding Efficiency

Small models process 50-500kg per hour while supporting continuous 24-hour operation. Processing efficiency exceeds traditional equipment by 15-20%, ensuring your production targets are consistently met.

Cost-Effective Operation

Durable Cutting Components

Alloy steel blades (SKD11, Cr12MoV) reach HRC55-60, last 3000-5000 hours, and can be reground 3-5 times, cutting replacement costs by 60% versus standard carbon steel.

Energy Efficient Design

Our optimized motor and transmission structure in the Small plastic shredder reduces energy consumption by 10–15% compared to conventional equipment. Processing one ton of plastic requires only 8–12 kWh, keeping your operating costs minimal.

Immediate Material Recovery

Transform waste into valuable resources instantly. Process runner material and production waste for immediate recycling. Mix crushed materials with new plastic at 3:7 to 5:5 ratios, increasing raw material utilization by 30-50% while saving thousands annually.

Safety and Reliability Features

Comprehensive Protection Systems

Thick steel construction, anti-rebound baffles, and safety shields protect operators. Select models feature interlocks that cut power when chambers open, preventing accidental injury.

Stable Performance

Precision bearings and hardened gears with regular lubrication design minimize mechanical wear. Dynamic balance testing ensures vibration remains below 0.1mm, preventing component loosening. Equipment failure rates decrease by 40% compared to standard models.

Easy Maintenance and Cleaning

Simple body design allows quick cavity side disassembly for thorough cleaning. This feature proves especially valuable when switching between different colored plastics to prevent contamination. Accessible maintenance points require no complete machine disassembly, reducing maintenance time by 50%.

Flexible Configuration Options

Ready to enhance your plastic processing capabilities? Contact us at postmaster@xingbiaocrusher.com to discuss your specific requirements and discover how our Small plastic shredder can optimize your operations today.

Learn about our latest products and discounts through SMS or email