Our bottle crusher handles 50 kg–10 t/hour, runs 24/7, and processes all bottle types—including PET, HDPE, and thick-walled—without needing multiple machines.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

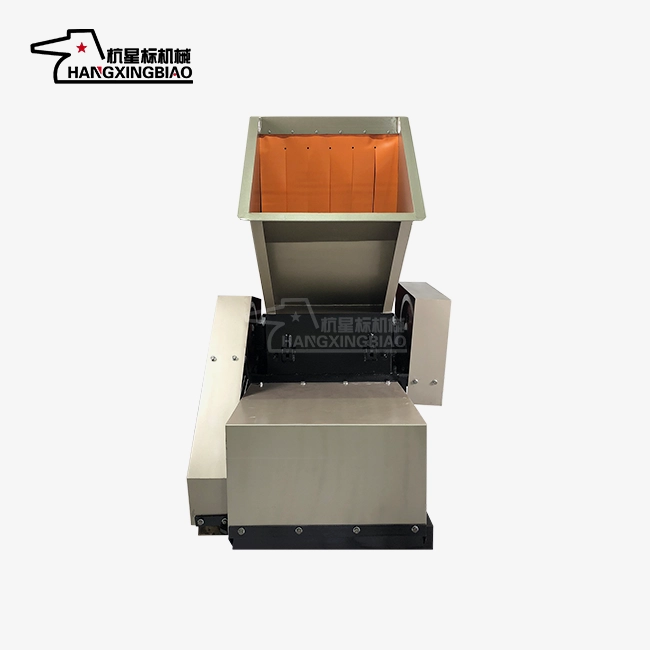

Mineral water bottle crusher

Mineral Water Bottle Crusher: Your Ultimate Solution for Plastic Bottle Recycling

Are you struggling with plastic bottle waste management in your facility? Our mineral water bottle crusher from Hangzhou Xingbiao Machinery is designed specifically for your recycling needs. This powerful machine transforms plastic bottles into reusable materials efficiently. With over 30 years of specialized experience in crusher manufacturing, we understand exactly what you need. Our crusher handles all types of plastic bottles with remarkable precision. You'll save money while contributing to environmental protection. The machine features robust construction and user-friendly operation.

Why Choose Our Plastic Bottle Crusher?

Exceptional Processing Capability

Superior Build Quality

High-strength, stress-relieved steel body with SKD-11 and Cr12MoV blades treated by vacuum heat offers HRC 55–60 hardness, 3,000–5,000 hours’ life, and 3–5 regrinds for extended durability and savings.

Smart Design Features

Quick-change screen structure saves your time. Different mesh sizes give you particle control from 2-50mm. The open design allows easy cleaning between batches. Safety shields protect operators during operation.

Our engineers designed the Mineral water bottle crusher layout for maximum efficiency. Material flow stays smooth without jamming. The optimized motor reduces energy consumption by 15%. Your operating costs drop while productivity increases.

Technical Advantages That Matter

Precision Output Control

Interchangeable screens allow precise particle sizes—coarse (5–50 mm) for pretreatment, medium (2–12 mm) for granulation—with over 90% uniformity. Adjustable speeds and blade configurations ensure consistent quality batch after batch.

Energy Efficiency

Efficient motors and optimized transmission reduce energy use to 8–12 kWh/ton. Precision bearings, hardened gears, and <0.1 mm vibration ensure smooth operation and 40% lower failure rates.

Safety and Reliability

Thick steel plates, anti-rebound baffles, and safety interlocks protect workers. Dynamic balancing, quality-checked components, and accessible maintenance points reduce vibration, upkeep, and repair time.

Flexible Model Options

Compact Mobile Units

Perfect for smaller operations or multiple locations. Universal wheels allow easy positioning. These units handle laboratory testing requirements. Processing capacity starts at 50kg hourly.

Fixed Production Models

Ideal for dedicated recycling lines. Floor installation provides stability. Medium-capacity processing suits most facilities. These models integrate with existing equipment.

Integrated Systems

Large-scale operations benefit from automated lines. Direct connection to granulators saves handling. Conveyor integration streamlines workflow. Maximum efficiency for high-volume processing.

Applications Beyond Basic Recycling

Your mineral water bottle crusher handles diverse recycling scenarios. Injection molding operations benefit from immediate scrap processing. Crushed materials mix with new plastic at 30-50% ratios. This recycling approach cuts raw material costs substantially.

Beverage companies use our crushers for returned bottle processing. Recycling centers rely on our equipment for daily operations. Manufacturing facilities process production waste efficiently. Food service companies manage container waste responsibly.

Expert Support and Service

Our 20-engineer team offers full support with 24-hour responses, installation guidance, training, follow-ups, spare parts, and maintenance advice, ensuring optimal performance and extended equipment life throughout ownership.

Cost-Effective Operation

Ready to transform your bottle waste into valuable resources? Our mineral water bottle crusher delivers reliable performance and exceptional value. Contact us at postmaster@xingbiaocrusher.com for detailed specifications and pricing. Start saving money while protecting the environment today.

Learn about our latest products and discounts through SMS or email