Hangzhou Xingbiao Machinery, focused 30 years on plastic crushers, combines deep expertise and industry partnerships to deliver continuously innovated, cutting-edge technology.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

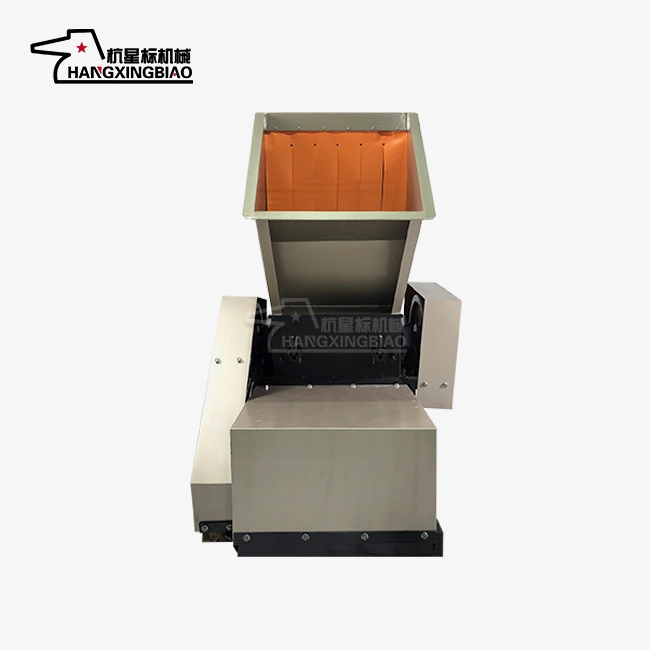

Industrial small crusher

Industrial Small Crusher - Heavy-Duty Plastic Processing Solution

Professional Crushing Equipment for Maximum Efficiency

Looking for reliable crushing equipment for your plastic processing needs? Our industrial small crusher delivers exceptional performance with processing capacities ranging from 50 to 2000kg per hour. This versatile machine handles continuous 24-hour operation while maintaining superior efficiency. Whether you need small-batch laboratory crushing or large-scale industrial production, our product adapts to your specific requirements with ease.

Built with robust construction and advanced engineering, these machines excel in various applications. From plastic waste recycling to manufacturing byproduct processing, they provide consistent results you can trust.

Why Choose Our Crushing Equipment?

Three Decades of Specialized Excellence

Superior Build Quality

The main body’s stress-relieved high-strength steel and SKD-11/D2/Cr12MoV blades with vacuum and cryogenic treatment ensure deformation-free, highly durable operation.

Enhanced Efficiency Design

Our unique blade layout and cavity structure boost crushing efficiency by over 20%. Optimized motor matching reduces energy consumption significantly. The streamlined design minimizes maintenance downtime while maximizing productivity.

Comprehensive Model Range

Flexible Processing Capacities

Multiple models accommodate diverse processing needs from laboratory scale to industrial production. Small units handle 50-500kg per hour, while large industrial models reach 1-10 tons hourly. Every machine supports continuous operation for demanding production schedules.

Wide Material Compatibility

These Industrial small crushers handle all plastic types effortlessly. Soft materials like PE/PVC films and woven bags process smoothly. Hard plastics including ABS/PC parts and thick-walled pipes break down efficiently. Foam materials such as EPS/EVA and irregular shapes like bottles and trays pose no challenges.

Precise Particle Control

Interchangeable screens (2–100 mm) and adjustable blades deliver precise, uniform particles (>90%) for coarse pretreatment or fine recycling without secondary screening.

Advanced Safety Features

Comprehensive Protection Systems

Enclosed steel chambers with anti-rebound baffles and external shields ensure operator safety; select models include interlocks that cut power when chambers open.

Low Noise Operation

Operating noise stays below 75dB through enclosed cavity design and specialized motors. This makes units suitable for workshops, laboratories, and environmentally sensitive locations. Effective dust containment prevents workplace contamination.

Built-in Overload Protection

Automatic shutdown systems activate when metal objects or other hard contaminants enter the chamber. This prevents equipment damage and ensures operational safety. Alert systems notify operators of potential issues immediately.

Cost-Effective Operation

Energy Efficient Performance

Advanced motor and transmission designs reduce energy consumption by 10-15% compared to conventional equipment. Processing one ton of plastic requires only 8-12 kilowatt-hours. Lower operating costs improve your bottom line significantly.

Durable Components

High-alloy steel cutting tools reach HRC55-60 hardness ratings. Tool life extends 3000-5000 hours for standard plastics. Tools support repeated sharpening for 3-5 cycles, reducing replacement costs by 60% versus carbon steel alternatives.

Immediate Material Recovery

Crush production waste including runners, sprues, and defective parts instantly with the Industrial small crusher. Recycled material blends with virgin plastic at 30–70% ratios. This increases raw material utilization by 30–50%, saving thousands in procurement costs annually.

Easy Maintenance Design

Quick Access Construction

Simple design enables quick chamber cleaning, prevents color contamination, and allows inspection/lubrication without full disassembly, reducing maintenance time by 50%.

Reliable Mechanical Systems

Precision bearings and hardened gears, with regular lubrication and dynamic balancing (<0.1 mm), ensure smooth operation and reduce failure rates 40% versus standard models.

Versatile Applications

Manufacturing Integration

Mobile units roll easily, fixed models integrate into lines, large units link to granulators/conveyors, and lab models support R&D activities.

Multi-Industry Solutions

Furniture manufacturers recycle production waste and process end-of-life plastic furniture. The crushed material returns to production cycles or combines with wood fibers for composite boards. This reduces raw material consumption while supporting sustainability goals.

Professional Support Services

Ready to enhance your plastic processing capabilities? Our industrial small crusher delivers the performance and reliability your operations demand. Contact us at postmaster@xingbiaocrusher.com for detailed specifications and expert consultation tailored to your specific requirements.

Learn about our latest products and discounts through SMS or email