For 30 years, we’ve focused solely on perfecting plastic crushing. Our team of 20 senior engineers drives continuous innovation, earning partnerships with brands like Nongfu Spring and KFC. You benefit from this specialized expertise as we concentrate exclusively on building the best crushers.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

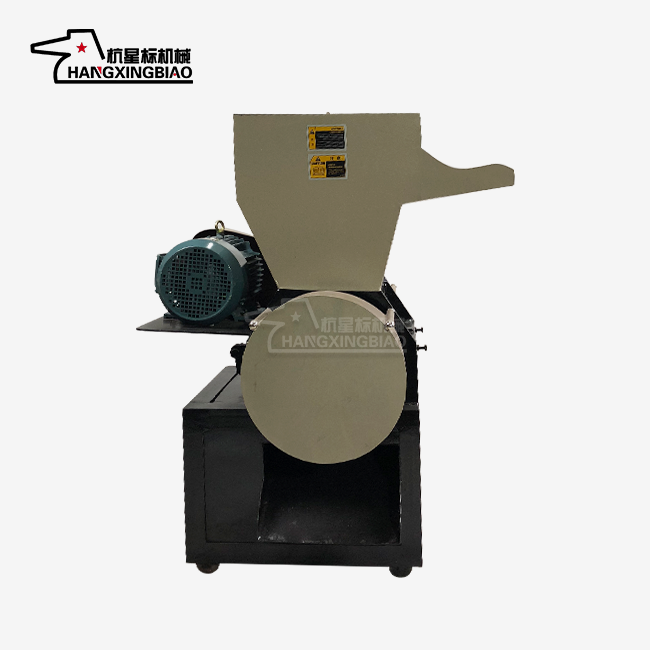

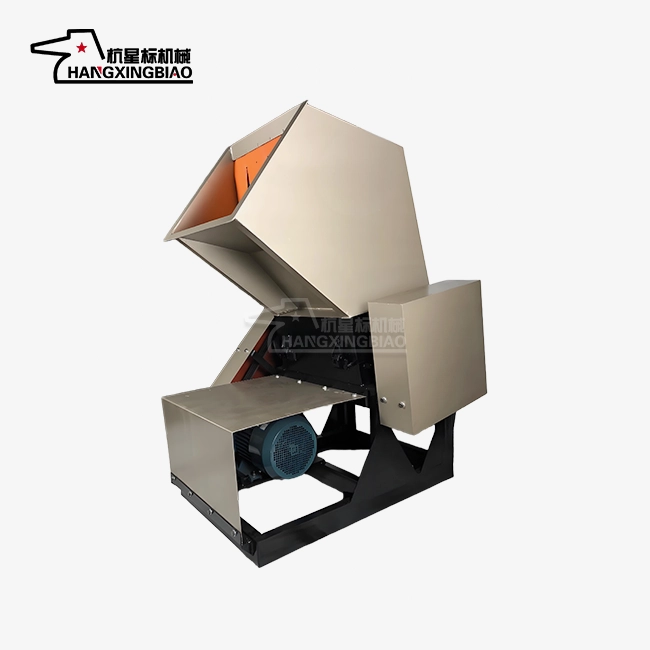

Industrial plastic crusher

Industrial Plastic Crusher - Efficient Recycling Solution for Your Business

Are you looking for a reliable and efficient industrial plastic crusher to transform your waste materials into valuable resources? Hangzhou Xingbiao Machinery brings you 30 years of specialized expertise in plastic crushing technology. Our product combines advanced engineering with proven durability to deliver exceptional performance for businesses of all sizes. Whether you're processing soft films or hard plastic parts, our crushers handle diverse materials with ease while maintaining consistent particle quality. Experience the difference that specialized focus makes in every aspect of your recycling operation.

Why Choose Our Advanced Plastic Crushing Solutions?

Specialized Expertise You Can Trust

Superior Build Quality That Lasts

Your crusher relies on high-strength, stress-relieved steel plates to prevent deformation. SKD-11/D2 blades receive heat and cryogenic treatment, maintaining sharpness for 3000+ hours. Our shear-plus-impact process ensures over 90% discharge uniformity with no secondary screening needed.

Comprehensive Product Range

We understand that different applications require different solutions:

Heavy-Duty Large-Diameter Models: Perfect for thick pipes, large plastic parts, and die head materials. These machines handle the toughest jobs without breaking down.

High-Power Centralized Feeding Systems: Designed for quiet operation alongside injection molding machines. Process sprue materials efficiently without disrupting your production floor.

Specialized Film Crushers: Our built-in anti-winding comb design prevents jamming when processing films, woven bags, and other fibrous materials.

Custom Solutions: Need something specific? We create tailored machines for unique materials like large trash cans or automotive components.

Outstanding Performance Features

Versatile Material Handling

Your industrial plastic crusher adapts to whatever materials you need to process. Soft plastics like PE films? No problem. Hard materials like ABS housings? Handled with ease. Foam packaging, irregular bottles, production scraps – one machine processes them all.

You won't need multiple crushers for different materials. Our design accommodates everything from delicate films to thick-walled pipes without equipment changes.

Precise Particle Control

Easily control output by changing 2–100 mm meshes for coarse or fine particles. Uniformity exceeds 90%, ensuring consistent results, eliminating sorting, and improving downstream processing efficiency.

Exceptional Efficiency

Process 50 kg to 10 tons per hour, with optimized motors and blade design boosting efficiency by 20%. Energy use remains low at just 8–12 kWh per ton, reducing consumption by 10–15% compared to traditional machines.

Cost-Effective Operation

Durable blades can be resharpened 3–5 times, cutting replacement costs by 60%. Immediate recycling saves raw material expenses, allowing up to 50% scrap mixing and boosting material utilization by 30–50%.

Safety and Reliability Built-In

Comprehensive Protection

Safety comes first with enclosed chambers, anti-rebound baffles, and interlocks that cut power when doors open. Thick steel construction and precise engineering keep vibration under 0.1 mm, reducing wear and extending service life.

Easy Maintenance

Quick-release chamber sides simplify cleaning during color changes, while accessible maintenance points cut service time by 50%. Clearly marked lubrication points support an easy routine that keeps the machine running with minimal downtime.

Contact Us

Ready to transform your plastic waste into valuable resources? Contact us at postmaster@xingbiaocrusher.com to discuss your industrial plastic crusher requirements. Our experts are standing by to help you find the perfect solution for your recycling needs.

Learn about our latest products and discounts through SMS or email