For three decades, we’ve focused solely on plastic crushing, becoming industry leaders in innovation and reliability. Our 20-engineer team brings deep expertise, collaborating with major brands like Nongfu Spring and KFC to drive continuous improvement in our processes.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

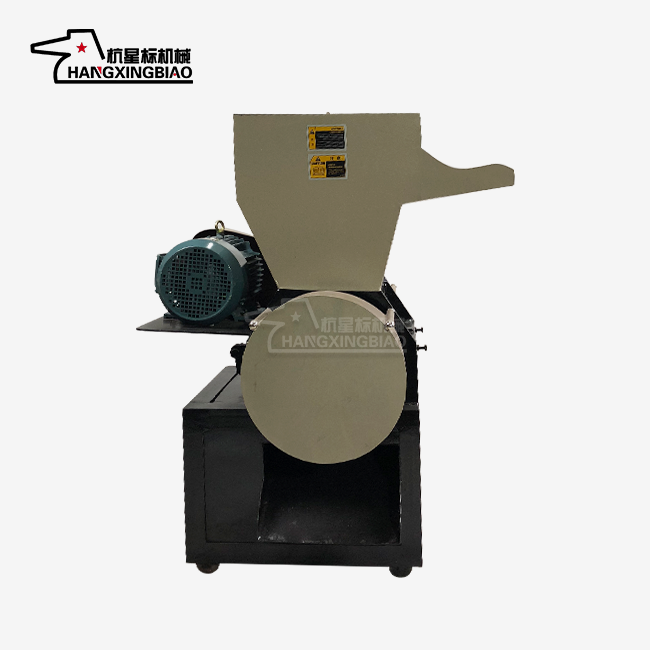

PET crusher

PET Crusher - Professional Plastic Recycling Solution

Are you looking for a reliable product to transform your plastic waste into valuable recycling materials? Your search ends here. Our advanced PET crusher delivers exceptional performance for businesses seeking efficient plastic recycling solutions. With over 30 years of specialized experience, Hangzhou Xingbiao Machinery offers cutting-edge technology that meets diverse industrial needs. Whether you're processing PET bottles, containers, or other plastic materials, our equipment ensures consistent results and maximum productivity for your operations.

Why Choose Our Plastic Crushing Equipment?

Unmatched Engineering Excellence

Superior Build Quality and Durability

Each machine uses high-strength, stress-relieved steel plates to prevent deformation. SKD-11/D2 and Cr12MoV blades receive vacuum heat and cryogenic treatment, delivering exceptional hardness, wear resistance, and long service life.

Exceptional Processing Efficiency

Our blade layout and cavity structure boost crushing efficiency by over 20%, while optimized motor matching lowers energy use. Capacity ranges from 50–2000 kg/h, and 24-hour continuous operation meets high-volume production demands.

Comprehensive Product Range

Standard Models

Perfect for everyday plastic recycling needs. These units handle various plastic types efficiently. They're ideal for small to medium-scale operations.

Heavy-Duty Systems

Designed for large plastic components, pipes, and profiles. These powerful machines tackle challenging materials with ease.

Specialized Low-Noise Units

Engineered for centralized feeding systems. Operating noise stays below 75dB. They're perfect for injection molding machine sprue recycling.

Custom Solutions

Tailored for unique applications like large-volume waste processing. We design equipment specific to your operational requirements.

Advanced Safety and Environmental Features

Complete Safety Protection

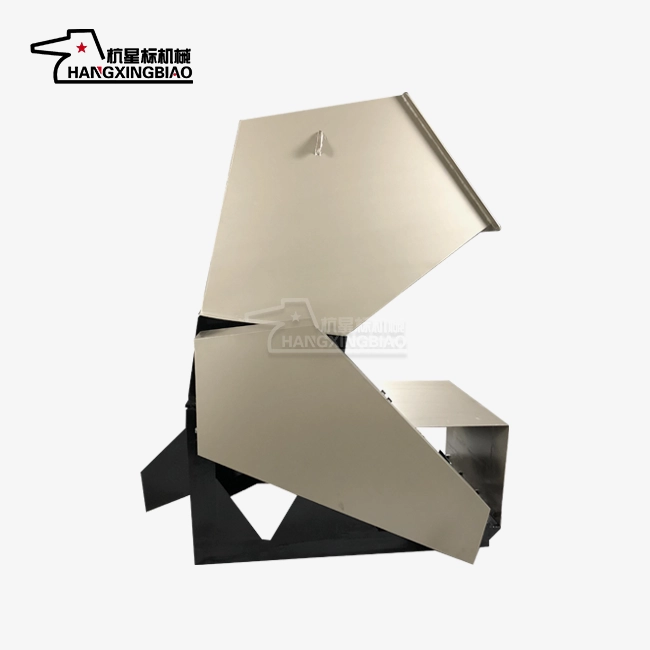

Our fully enclosed design prevents dust leakage and reduces noise. Thick steel chamber construction and anti-rebound baffles protect the inlet. Exterior safety shields and optional interlock systems cut power when opened, preventing operator injuries.

Intelligent Overload Protection

Built-in protection devices monitor operations continuously. The system automatically shuts down when detecting metal contaminants. This prevents equipment damage and ensures operational safety.

Versatile Material Processing

Our equipment handles diverse plastic types effortlessly. Soft plastics like PE/PVC films and woven bags process smoothly. Hard plastics including ABS/PC components crush efficiently.

The PET crusher excels with foam materials like EPS/EVA. Irregular shapes such as bottles and trays present no challenges. You won't need frequent equipment changes or structural adjustments.

Precise Particle Size Control

Interchangeable screening nets offer 2-100mm options. This flexibility produces various output sizes for different applications. Coarse fragments (5-50mm) work perfectly for pretreatment processes.

Medium particles (2-12mm) suit granulation and injection recycling perfectly. Particle uniformity exceeds 90%. This eliminates secondary screening requirements.

Cost-Effective Operation

Extended Tool Life

Core cutting tools use premium alloys with HRC55–60 hardness, delivering 3000–5000 hours of service life. They support 3–5 regrinding cycles, reducing replacement costs by 60% compared with standard carbon steel alternatives.

Energy Efficiency

Efficient motors paired with optimized transmission structures reduce energy consumption by 10-15%. Processing one ton of plastic requires only 8-12 kWh of electricity.

Easy Maintenance and Cleaning

Simple body design allows quick cavity disassembly. This facilitates easy cleaning when switching between different plastic colors. Exposed maintenance points enable inspection and lubrication without complete machine disassembly.

Maintenance time reduces by 50% compared to traditional equipment. Regular upkeep becomes straightforward and cost-effective.

Complete Service Support

The PET crusher represents our commitment to quality and innovation. Contact us at postmaster@xingbiaocrusher.com to discuss your specific requirements. Let our expertise transform your plastic recycling operations into profitable, efficient processes.

Learn about our latest products and discounts through SMS or email