Interchangeable 2–100 mm screens deliver over 90% uniformity, removing the need for secondary screening. Easily adjust output from 5–50 mm coarse fragments to 2–12 mm fine particles for granulation.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

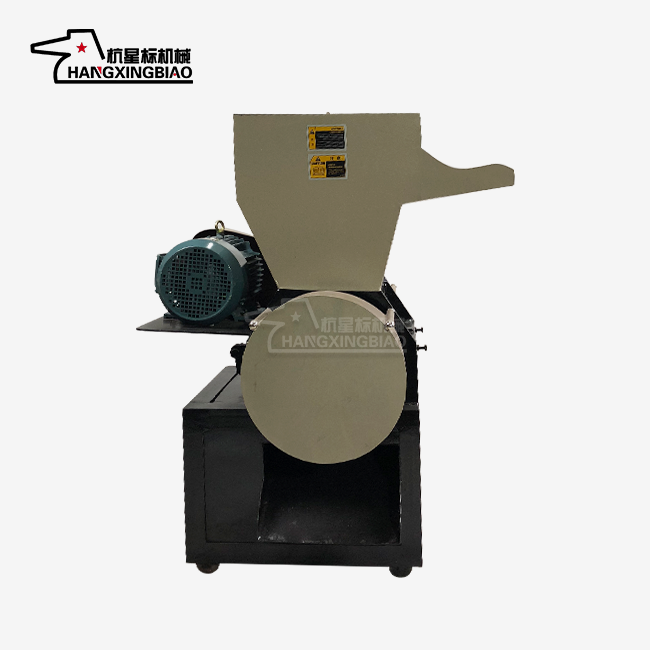

PVC crusher

High-Performance PVC Crusher: Professional Plastic Recycling Solutions

Looking for a reliable PVC crusher to streamline your plastic recycling operations? Our progressed plastic pulverizing gear conveys remarkable execution for handling PVC channels, sheets, profiles, and different plastic materials. Outlined with cutting-edge innovation and built to final, this industrial-grade crusher changes squander PVC into important reusable materials whereas decreasing your working costs. Whether you're running a little workshop or large-scale reusing office, our flexible pulverizing arrangements adjust to your particular preparing needs with exceptional productivity and reliability.

Why Choose Our Advanced Plastic Crushing Equipment?

Proven Engineering Excellence

Hangzhou Xingbiao Apparatus offers 30 a long time of plastic pulverizing mastery. Our 20 senior engineers enhance ceaselessly, joining forces with industry pioneers to provide high-performance, strong smashing solutions.

Built for Durability and Performance

Our crushers use high-strength, stress-relieved steel and SKD-11/D2 and Cr12MoV blades treated with vacuum heat and cryogenic processes, ensuring no deformation, maximum hardness, and exceptional wear resistance.

Superior Processing Efficiency

Our optimized edge format and chamber boost effectiveness by over 20%, whereas energy-efficient engines keep up unfaltering yield. Little models prepare 50–500 kg/h, and mechanical units reach 1–10 tons/h.

Versatile Material Processing Capabilities

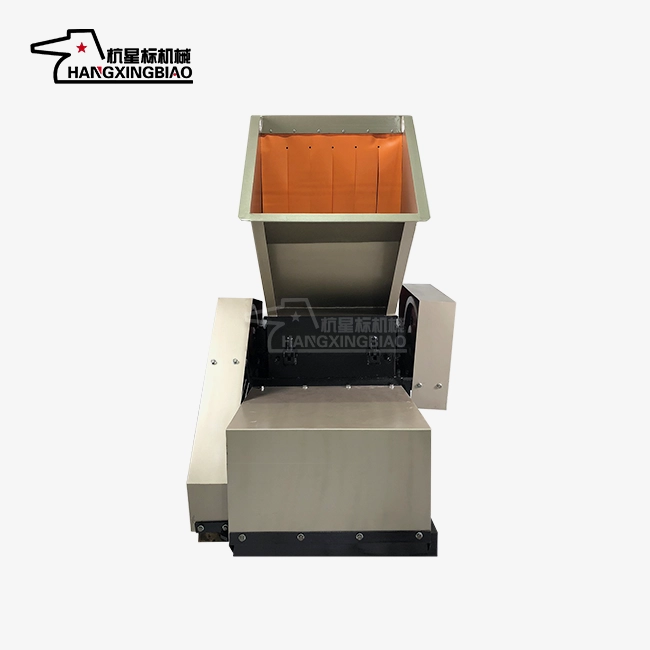

Complete PVC Processing Solution

This PVC crusher efficiently handles all types of PVC materials including rigid pipes, flexible sheets, foam products, and irregular shaped waste. The equipment processes both soft plastics like PE/PVC films and hard materials such as ABS/PC components without requiring structural modifications.

Precision Size Control

Extended Blade Life

High-performance cutting tools deliver 3000-5000 hours of service life with ordinary plastics. The blades support repeated sharpening (3-5 cycles), reducing replacement costs by 60% compared to standard carbon steel alternatives.

Cost-Effective Operation Benefits

Immediate Waste Recovery

Transform waste into reusable raw material by mixing crushed and virgin plastics at 30–50%, boosting utilization and saving significant annual material and disposal costs.

Energy-Efficient Design

Advanced engine and transmission frameworks cut vitality utilization by 10-15% versus customary crushers. Preparing one ton of plastic requires as it were 8-12 kWh, keeping your operational costs sensible.

Minimal Maintenance Requirements

The simplified design allows quick chamber access for cleaning and maintenance. Key components remain easily accessible without full disassembly. Regular maintenance time decreases by 50% thanks to intelligent engineering.

Safety and Reliability Features

Comprehensive Protection Systems

Fully enclosed steel chambers, anti-rebound shields, and safety interlocks ensure safe operation by preventing ejection and automatically cutting power when doors open.

Stable, Low-Vibration Operation

Precision bearings and hardened gears minimize mechanical wear in the PVC crusher. Dynamic-balanced rotors and screens limit vibration to 0.1 mm amplitude. This stability reduces component loosening and cuts failure rates by 40% compared to standard models.

Flexible Configuration Options

Scalable Solutions

Choose from mobile units with universal wheels for flexible positioning, fixed installations for dedicated production lines, or integrated systems linking with granulators and conveyors. Models range from laboratory-scale (50kg/h) to industrial capacity (10t/h).

Customization Available

Our engineering team designs custom solutions for unique processing requirements. Whether handling oversized materials or specialized plastic types, we'll configure equipment matching your exact specifications.

Technical Support and Service

Expert Consultation

Professional engineers provide comprehensive selection guidance and processing solutions tailored to your applications. We analyze your materials, throughput requirements, and facility constraints to recommend optimal equipment configurations.

Comprehensive After-Sales Care

Receive 24-hour response times for technical inquiries, complete installation guidance, and operator training programs. Regular follow-up visits ensure peak performance while adequate spare parts inventory minimizes downtime.

Investment in Quality Equipment

Ready to transform your plastic waste into profit? Contact our specialists at postmaster@xingbiaocrusher.com today. We'll help you select the perfect PVC crusher configuration for your specific requirements and budget.

Learn about our latest products and discounts through SMS or email