Our crushers handle all plastics effortlessly. Soft PE films and woven bags crush smoothly, while ABS parts and thick pipes break down efficiently. Foam and irregular shapes like bottles or trays process cleanly. One machine covers all materials without dust or wrapping issues.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

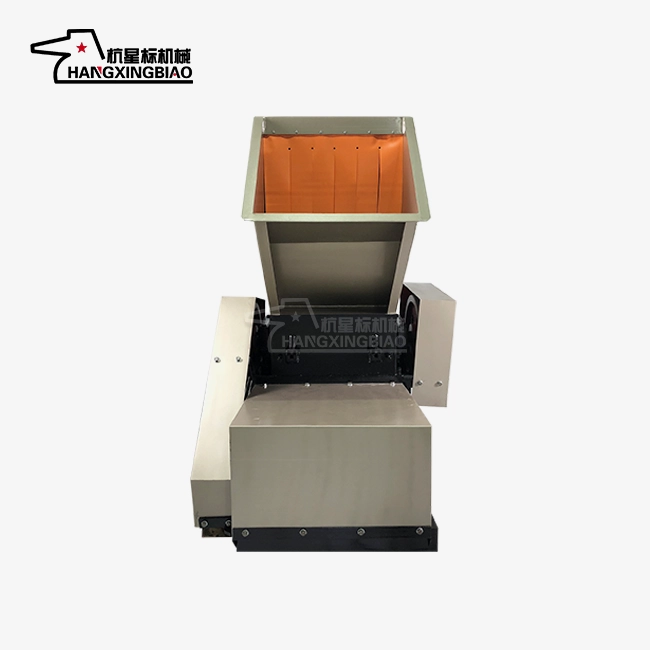

High efficiency crusher

High Efficiency Crusher - Professional Plastic Processing Solution

Are you struggling with plastic waste management or looking to improve your material recycling process? Our High efficiency crusher from Hangzhou Xingbiao Machinery provides the perfect solution for your plastic processing needs. Outlined with progressed innovation and built to final, this hardware changes squander plastic materials into profitable assets proficiently. Whether you run a little workshop or expansive mechanical office, our crusher conveys solid execution that spares you time and cash whereas ensuring the environment.

Why Choose Our Professional Crushing Equipment?

Superior Build Quality and Durability

Our crushers utilize high-strength steel plates with push alleviation, guaranteeing long-term shape and execution. Center edges of SKD-11/D2 steel experience vacuum warm and cryogenic treatment, conveying extraordinary hardness, wear resistance, and 3000-5000 hours of pulverizing life.

Exceptional Handling Capabilities

Processing capacity ranges from 50kg to 2000kg/hour, supporting lab to mechanical operations with 24-hour ceaseless utilize. Interesting edge format and optimized depth increment effectiveness over 20%, guaranteeing smooth fabric stream, anticipating blockages, and boosting efficiency.

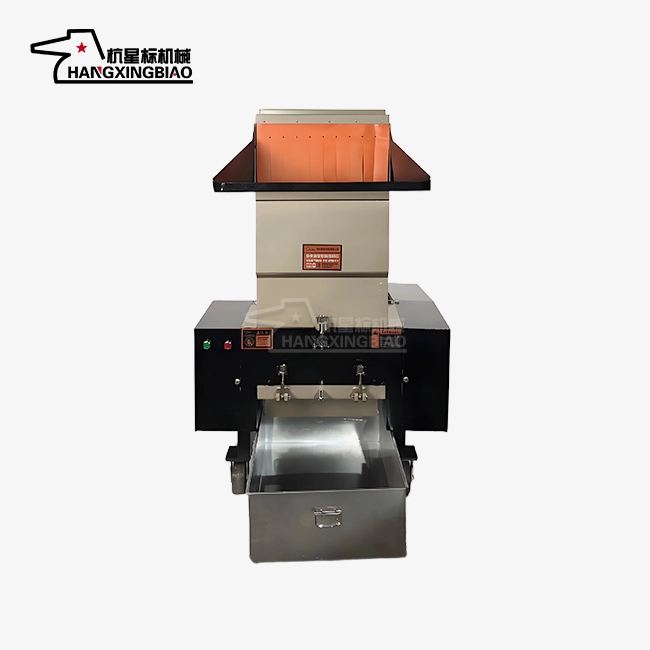

Smart Safety Features

Safety comes first in our equipment design. Each High efficiency crusher includes built-in overload protection that automatically shuts down when metal objects enter the chamber. This prevents expensive damage and keeps your operators safe.

The fully enclosed chamber design blocks dust and reduces noise to just 75dB during operation. Anti-rebound baffles at the feed opening prevent material from flying back. Some models feature safety interlocks that cut power when you open the chamber door.

Versatile Material Handling

Advanced Design Features

Precision Particle Size Control

Control output size precisely with 2-100mm screen meshes. Produce coarse fragments or fine particles with over 90% uniformity. Adjustable blade speeds and configurations optimize material handling, saving processing steps and improving product quality.

Energy Efficient Operation

The optimized motor and transmission system reduces energy consumption by 10-15%. Processing one ton of plastic uses only 8-12 kilowatt-hours of electricity. Lower operating costs mean better profits for your business.

Precision bearings and hardened gears ensure smooth power transmission. Regular lubrication points maintain peak efficiency throughout the equipment's life. This careful engineering translates to lower utility bills.

Easy Maintenance and Cleaning

The simple design of the High efficiency crusher allows quick side panel access for easy cleaning, preventing color contamination. Key components remain accessible for inspection and lubrication. Maintenance time drops 50%, with fast blade sharpening and replacement minimizing downtime.

Complete Model Range

Compact Models for Small Operations

Mobile units with wheels move easily between workstations. These handle 50-500kg per hour, perfect for injection molding sprue recycling or small-batch processing. The compact footprint fits limited floor space.

Industrial Fixed Units

Floor-mounted models deliver 1-3 tons per hour processing capacity. These integrate seamlessly into existing production lines. Heavy-duty construction handles the most demanding applications reliably.

Large-Scale Processing Systems

Our largest units process up to 10 tons per hour. These can link with granulators and conveyors for fully automated recycling lines. Custom configurations match your specific production requirements.

Professional Support and Service

Ready to improve your plastic processing efficiency? Contact our experts at postmaster@xingbiaocrusher.com to discuss your High efficiency crusher requirements. We'll help you select the perfect model for your application.

Learn about our latest products and discounts through SMS or email