Our crushers use a “shear + impact” system with optimized cavity and blade spacing for 90% uniform discharge. The anti-winding comb design prevents jamming and reduces maintenance downtime.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

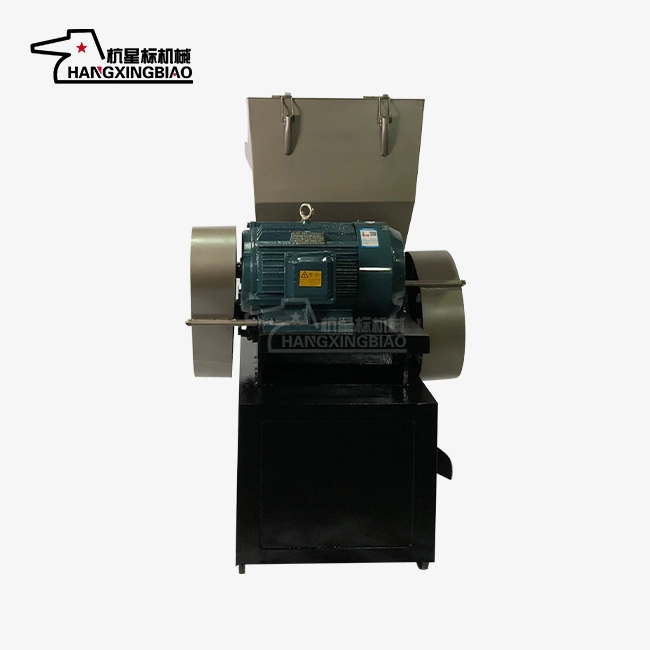

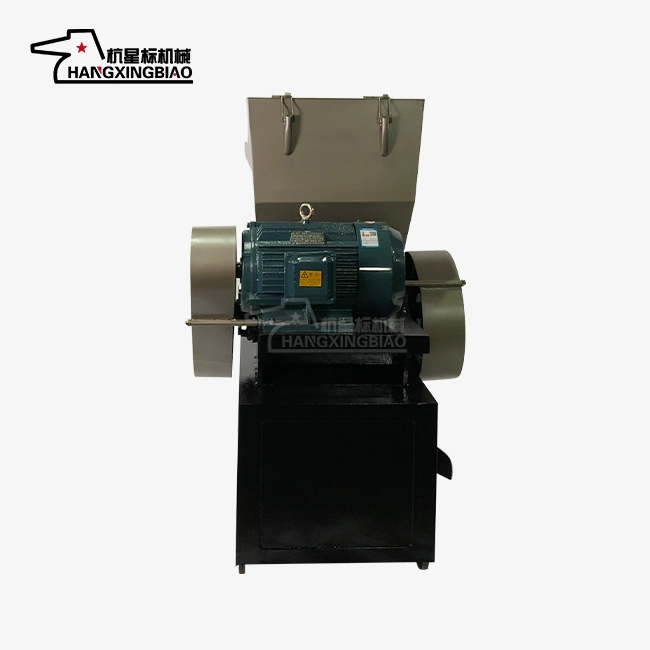

mini plastic crusher machine

Mini Plastic Crusher Machine - Complete Solution for Your Plastic Recycling Needs

Are you tired of dealing with mounting plastic waste in your workshop or production facility? Our mini plastic crusher machine offers the perfect solution for small to medium-scale plastic recycling operations. Designed with precision and built to last, this compact powerhouse transforms plastic waste into valuable recyclable materials efficiently and cost-effectively. This versatile machine processes sprues, bottles, and films with consistent results, transforming your waste management efficiency.

Why Choose Our Compact Plastic Shredding Equipment?

Superior Build Quality That Stands the Test of Time

Our compact crushers use high-strength steel for lasting durability. Blades made from SKD-11 and Cr12MoV undergo vacuum heat and cryogenic treatment, achieving HRC55-60 hardness and over 3000 hours of wear-resistant performance.

Innovative Dual-Action Crushing Technology

Versatile Material Compatibility

Process virtually any plastic material with confidence:

- Soft plastics: PE/PVC films, woven bags, flexible packaging

- Hard plastics: ABS/PC components, thick-walled pipes, rigid containers

- Foam materials: EPS/EVA cushioning, packaging foams

- Irregular shapes: Bottles, trays, production scraps

No frequent equipment changes or structural adjustments needed. One mini plastic crusher machine handles multiple crushing scenarios seamlessly.

Outstanding Performance Specifications

Processing Capacity That Meets Your Demands

Small models process 50-500kg of material per hour. Larger industrial versions reach 1-10 tons hourly capacity. All models support 24-hour continuous operation for maximum productivity.

Our optimized design increases crushing efficiency by 15-20% compared to traditional equipment. This means faster material processing and reduced operational bottlenecks.

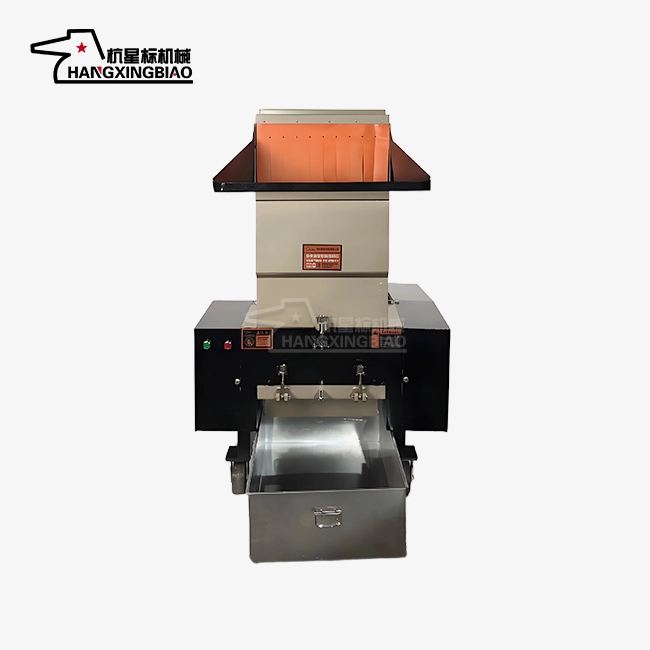

Precise Particle Size Control

Achieve exact specifications through interchangeable screening nets (2-100mm options). Adjust tool speed or change blade sets for different output requirements:

- Coarse fragments (5-50mm): Perfect for pretreatment applications

- Medium particles (2-12mm): Ideal for granulation and injection recycling

Particle uniformity exceeds 90% consistently, eliminating costly secondary processing steps.

Exceptional Energy Efficiency

Our efficient motor and optimized transmission structure reduce energy consumption by 10-15%. Processing one ton of plastic requires only 8-12 kilowatt-hours. This translates to significant cost savings over extended operation periods.

Advanced Safety and Maintenance Features

Comprehensive Safety Protection

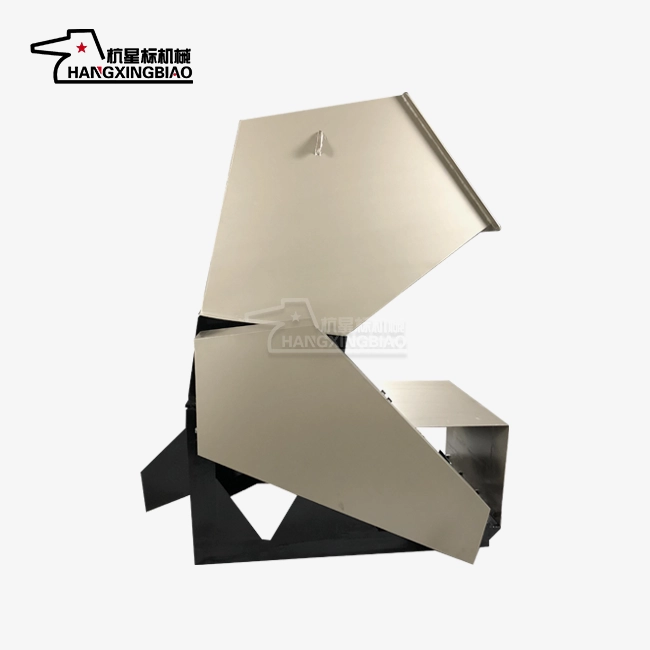

Your team's safety comes first. Our fully enclosed design includes:

- Welded thick steel plate crushing chamber

- Anti-rebound baffles at feed inlets

- External safety shields blocking material splash

- "Open-and-stop" interlocking system for accident prevention

Simplified Maintenance Design

Our user-friendly design cuts maintenance time by 50%. Quick-change screens and open access simplify cleaning, while precision bearings, hardened gears, and balance testing ensure low wear, minimal vibration, and long-term stability.

Cost-Effective Recycling Solution

Transform waste into profit through immediate scrap recycling. Process injection molding nozzle materials and production scraps instantly. Crushed materials blend directly with new materials in 3:7 to 5:5 ratios.

This recycling capability increases raw material utilization by 30-50%. Many customers save tens of thousands annually on material procurement costs alone.

The mini plastic crusher machine blade system supports 3-5 regrinding cycles, reducing replacement costs by 60% compared to standard carbon steel alternatives.

Customizable Models for Every Application

Choose from three main configurations:

- Mobile units: Compact designs with universal wheels for flexible positioning

- Fixed installations: Medium-capacity floor-mounted systems for production lines

- Integrated systems: Large-scale units linking with granulators and conveyors

From laboratory testing (50kg/h) to large recycling operations (10t/h), we cover your complete capacity requirements.

Professional Support and Service

Ready to transform your plastic waste management? Contact us at postmaster@xingbiaocrusher.com today. Discover how our mini plastic crusher machine can boost your recycling efficiency while reducing operational costs significantly.

Learn about our latest products and discounts through SMS or email