Our machine uses a “shear + impact” dual process with optimized cavity and blade spacing, preventing over-crushing and ensuring over 90% uniform discharge above 2 mm, eliminating secondary screening.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

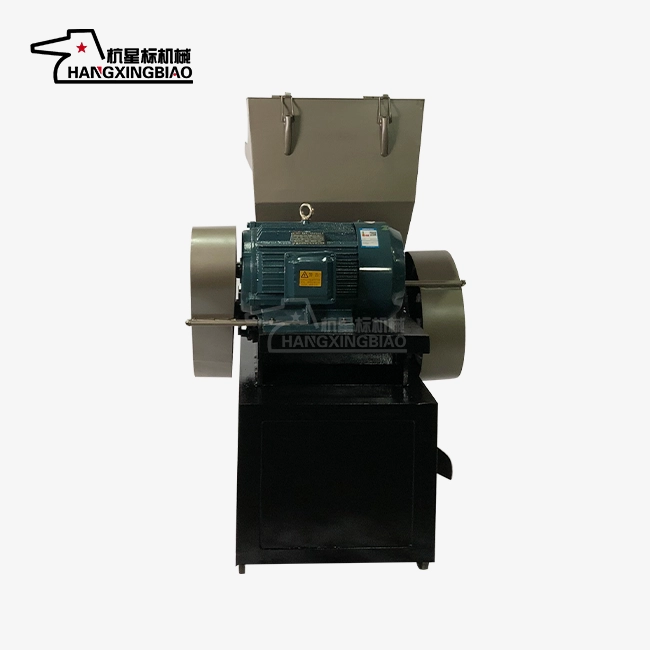

Small plastic crusher

Small Plastic Crusher: Powerful and Efficient Solution for Plastic Waste Processing

Are you looking for a reliable solution to process plastic waste efficiently? Our small plastic crusher is designed to meet your exact needs. Whether you're running a little workshop or overseeing a medium-scale reusing operation, this machine conveys uncommon execution. You'll appreciate how this compact however capable hardware changes different plastic materials into uniform particles. The item highlights progressed pulverizing innovation that guarantees reliable comes about each time. With over 30 a long time of specialization in plastic smashing hardware, Hangzhou Xingbiao Apparatus brings you demonstrated skill and predominant quality.

Why Choose Our Product?

Advanced Dual-Effect Crushing Technology

Built-in Anti-Winding Design

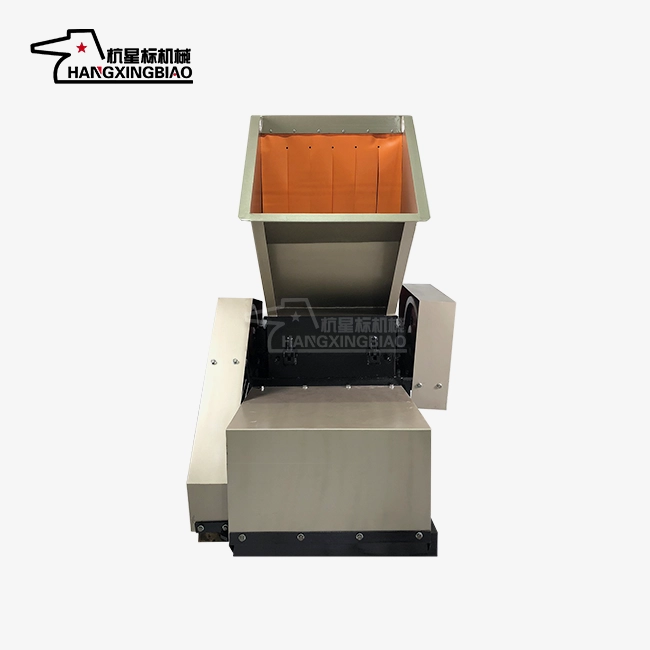

Dealing with challenging materials like fabric, paper, or films? Our built-in anti-winding comb tooth design prevents jamming and material entanglement. This feature keeps your operation running smoothly without frustrating interruptions.

Superior Blade Quality and Durability

Core edges made from SKD-11/D2 and Cr12MoV experience vacuum warm and cryogenic treatment, conveying tall hardness, solid wear resistance, and over 3000 hours of benefit life with lower support costs.

Versatile Material Processing Capabilities

Wide Material Compatibility

Your small plastic crusher handles diverse plastic types effortlessly:

- Soft plastics: PE/PVC films, woven bags, and flexible materials

- Hard plastics: ABS/PC parts, thick-walled pipes, and rigid components

- Foam materials: EPS/EVA buffer foam and lightweight plastics

- Irregular shapes: Plastic bottles, trays, and miscellaneous scraps

Precise Particle Size Control

You can achieve exact particle sizes by selecting different screening nets (2-100mm options available). The system produces:

- Coarse fragments (5-50mm): Perfect for pretreatment processes

- Medium particles (2-12mm): Ideal for granulation and injection molding recycling

Exceptional Performance and Efficiency

High Processing Capacity

Depending on your show choice, you can handle 50-500kg of materials per hour. The hardware bolsters nonstop 24-hour operation, assembly requesting generation plans. You'll encounter 15-20% higher smashing effectiveness compared to conventional equipment.

Energy-Efficient Operation

Our optimized engine and transmission plan decreases vitality utilization by 10-15%. Handling one ton of plastic regularly requires as it were 8-12 kWh of power, keeping your working costs reasonable.

Immediate Waste Recycling

In injection molding and extrusion scenarios, you can immediately crush runner materials and waste scraps. The processed material blends directly with new materials at 3:7 or 5:5 ratios, increasing raw material utilization by 30-50%.

Safety and Reliability Features

Comprehensive Safety Protection

Your safety is ensured through a thick welded chamber with anti-rebound baffles, external shields that block material splash, and interlock devices that cut power automatically when the chamber is opened.

Stable Operation Design

The transmission system incorporates precision bearings and hardened gears with regular lubrication systems. Key components undergo dynamic balance testing, maintaining vibration amplitude ≤0.1mm. This design reduces equipment failure rates by 40% compared to standard models.

Easy Maintenance and Flexibility

Simple Maintenance Access

The simple body design enables quick side disassembly for fast cleaning when changing plastic colors. Key maintenance points stay accessible for easy inspection and lubrication without dismantling the entire machine.

Customizable Solutions

We offer various configurations to match your specific requirements:

- Mobile units: Compact with universal wheels for flexible positioning

- Fixed installations: Medium-scale floor-mounted units for production lines

- Integrated systems: Large-scale units linking with granulators and conveyors

Expert Support and Service

Ready to transform your plastic waste processing? Contact us at postmaster@xingbiaocrusher.com to discuss your specific requirements and discover how our small plastic crusher can enhance your operations with reliable, efficient performance.

Learn about our latest products and discounts through SMS or email