Smaller models process 50–500 kg/h, while industrial units handle 1–10 t/h. They support 24-hour continuous operation with 15–20% higher efficiency and no material buildup or blockages.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

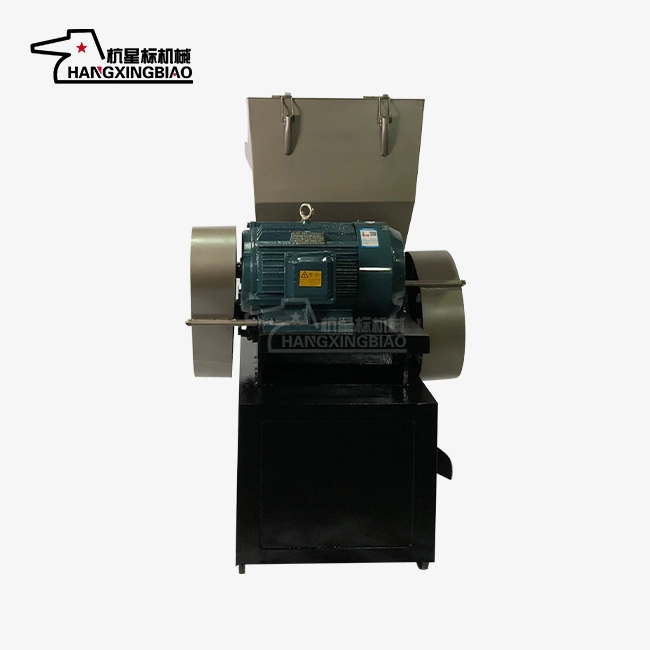

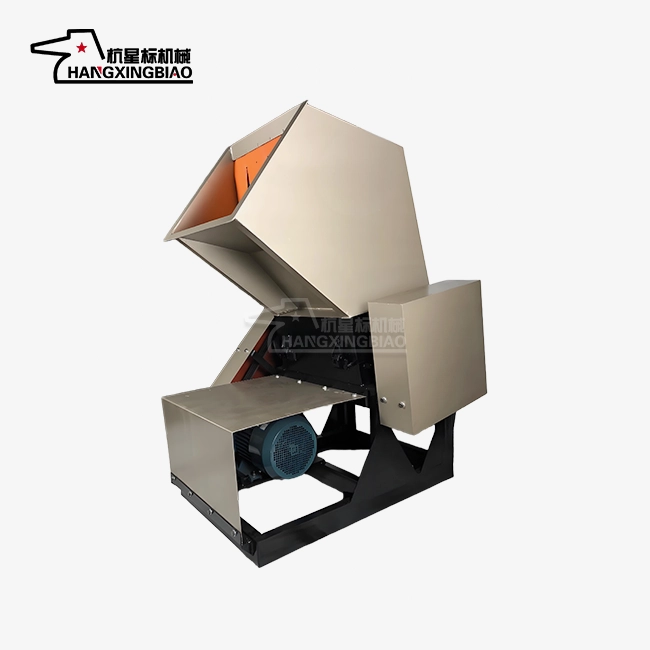

tree branch crusher

Tree Branch Crusher: Your Ultimate Solution for Efficient Wood Processing

Are you looking for a reliable and efficient solution to handle tree branches and woody materials? Our advanced tree branch crusher combines cutting-edge technology with robust construction to deliver exceptional performance for your wood processing needs. Designed with dual-effect crushing technology, this machine transforms branches, wood blocks, and fibrous materials into uniform particles with remarkable efficiency. Whether you're managing garden waste, processing lumber scraps, or running a recycling operation, our equipment provides the reliability and precision you demand for consistent results.

Key Features That Set Our Crusher Apart

Dual-Effect Crushing Technology

Our “shear + impact” process with optimized cavity and blade spacing prevents over-crushing, ensuring clean 2 mm+ discharge with minimal powder impurities and preserved particle integrity.

Anti-Winding Design Excellence

The built-in anti-winding comb tooth design prevents jamming when processing fibrous materials like bark strips, paper, and fabric components often found mixed with organic waste. This feature ensures continuous operation without frustrating blockages.

Superior Blade Construction

Each unit comes equipped with high wear-resistant alloy cutters designed for hard materials including hardwood blocks and dense plastics. These professional-grade blades deliver over 3000 hours of service life, reducing frequent replacement costs and maximizing your operational efficiency.

Exceptional Material Compatibility

Wide Range Processing Capability

Your crusher handles diverse materials effortlessly. From soft organic matter to dense hardwood pieces, the versatile design accommodates various material types without requiring structural adjustments or equipment changes. One machine covers multiple processing scenarios.

Flexible Particle Size Control

Adjustable screening nets (2–100 mm), tool speeds, and knife setups let you produce coarse or medium particles with over 90% uniformity for precise, application-specific results.

Performance Specifications

High Processing Efficiency

Energy Efficient Operation

The optimized motor and transmission structure combination of the tree branch crusher reduces energy consumption by 10-15% compared to conventional machines. Processing one tonne of material requires only 8-12 kWh, keeping operational costs manageable.

Built for Durability and Safety

Robust Construction Standards

Core cutting components use SKD11, HSS, and Cr12MoV alloys hardened to HRC55–60 for long life. The stress-relieved, high-strength steel body prevents deformation during extended operation.

Comprehensive Safety Features

Fully enclosed design includes thick steel plate crushing chambers, anti-rebound feed inlet baffles, and external safety shields. Selected models feature "open-and-stop" interlocking devices that automatically cut power when accessing the chamber, preventing operational accidents.

Low Maintenance Requirements

Precision bearings and hardened gears in the transmission system include regular lubrication design to minimize mechanical wear. Key components undergo dynamic balance testing with vibration amplitude ≤0.1mm, reducing failure rates by 40% compared to standard models.

Customization Options Available

Flexible Model Selection

Choose mobile, fixed, or conveyor-integrated units, with capacities ranging from 50 kg/h for labs to 10 t/h for large-scale production.

Easy Maintenance Design

Simple body construction allows quick cavity side disassembly for thorough cleaning. Key maintenance points remain accessible for daily inspection and lubrication without complete machine disassembly, reducing maintenance time by 50%.

Why Choose Hangzhou Xingbiao Machinery?

With 30 years of crushing equipment expertise and a 20-member engineering team, we deliver reliable, stress-relieved steel construction and premium cutting components. Our full service includes fast 24-hour support, installation guidance, training, and complete spare parts supply.

Experience the Difference

Ready to transform your material processing capabilities? Our tree branch crusher represents the perfect balance of performance, durability, and value. Contact our team today at postmaster@xingbiaocrusher.com to discuss your specific requirements and discover how our equipment can enhance your operations.

Learn about our latest products and discounts through SMS or email