Our machine handles soft films, woven bags, hard plastics, thick pipes, foam, and irregular bottles smoothly, with no frequent equipment changes or adjustments needed.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

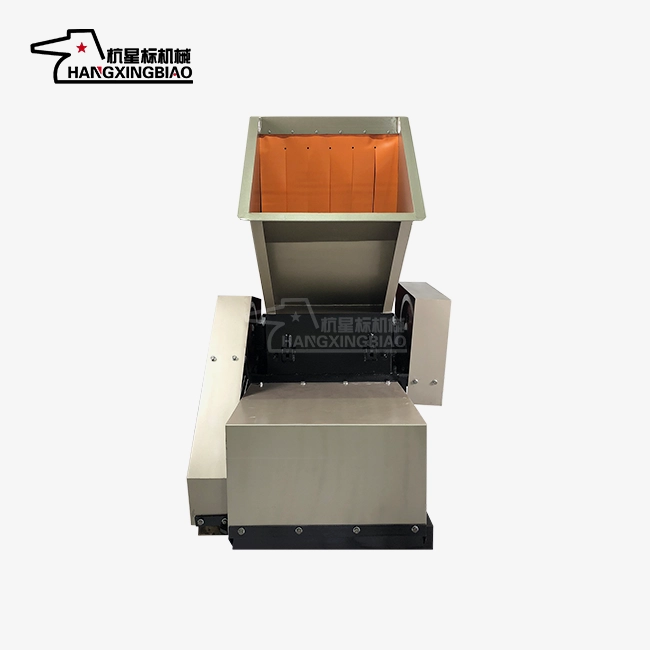

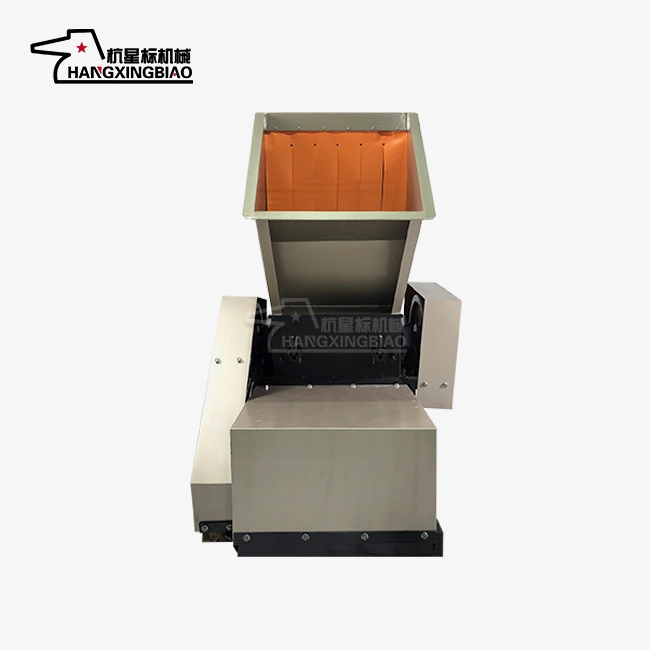

powerful pulverizer

Powerful Pulverizer: Industrial Crushing Solution for Multi-Material Processing

Your Complete Material Processing Solution

Looking for a reliable crushing solution that handles multiple materials with ease? Our powerful pulverizer breaks traditional limitations by efficiently processing almost all non-metallic materials. Whether you're dealing with plastics, rubber, wood, paper, or industrial waste, this versatile machine delivers consistent results. Unlike conventional crushers limited to single material types, our product adapts to blocks, flakes, fibers, and irregular forms. You get stable coarse and medium crushing with particle sizes adjustable from 2-50mm through interchangeable screens.

Why Choose Our Advanced Crushing Technology?

Unmatched Material Compatibility

Superior Processing Efficiency

Small units handle 50–500 kg/hour, industrial 1–10 t/hour, running 24/7 with 15–20% higher efficiency, eliminating material accumulation and blockages.

Precise Particle Size Control

Adjust screens (2–100 mm), tool speed, or knives to produce coarse (5–50 mm) or medium (2–12 mm) particles with over 90% uniformity, no secondary screening needed.

Built for Durability and Cost Savings

Premium Tool Construction

Core tools use SKD11, high-speed steel, and Cr12MoV, HRC 55–60, lasting 3,000–5,000 hours, resharpenable 3–5 times, cutting replacement costs 60% versus carbon steel.

Energy-Efficient Operation

Operating costs matter. Our efficient motor and optimized transmission structure reduce energy consumption by 10-15% compared to traditional equipment. Process one ton of plastic using only 8-12 kilowatts of electricity. Lower energy bills mean better profit margins.

Immediate Scrap Recycling Benefits

Transform waste into savings by crushing injection molding scraps for 30–50% higher raw material utilization, mixing with new materials for direct recycling and significant annual cost reductions.

Safety and Reliability Features

Comprehensive Protection Design

Safety-first design includes thick steel chambers, anti-rebound baffles, external shields, and interlocks that cut power when opened, preventing accidental injuries.

Stable, Low-Maintenance Operation

Minimize downtime with precision bearings and hardened gears in the transmission system of the powerful pulverizer. Regular lubrication design reduces mechanical wear. Key components undergo dynamic balance testing with vibration amplitude ≤0.1mm. Equipment failure rates drop 40% compared to standard models.

Flexible Model Options

Customized to Your Needs

Choose from mobile units with universal wheels for flexible positioning, fixed medium-sized models for production lines, or integrated large systems linking with granulators and conveyor belts. Coverage spans laboratory testing (50kg/h) to large-scale recycling operations (10t/h).

Easy Maintenance Access

Simple design halves service time, enabling quick cavity cleaning, easy color changes, and exposed maintenance points for daily inspection and lubrication without full disassembly.

Industry Applications

Toy and Sports Equipment Manufacturing

Convert production waste into profit by crushing injection molding flash, old toys, and damaged sports items for reuse in new plastic products.

Plastic Processing and Recycling

Meet growing recycling demands efficiently. Handle diverse plastic waste streams from bottles to industrial components. Support circular economy initiatives while maintaining profitability through reduced raw material costs and improved processing efficiency.

Technical Excellence You Can Trust

Hangzhou Xingbiao Machinery, with 30 years in crusher development, delivers high-quality machines using stress-relieved steel and SKD-11/D2/Cr12MoV blades with vacuum and cryogenic treatment for exceptional hardness and wear resistance.

Get Started Today

For detailed specifications and custom solutions, reach out to postmaster@xingbiaocrusher.com today. Let us help you maximize processing efficiency with a powerful pulverizer while minimizing operational costs.

Learn about our latest products and discounts through SMS or email