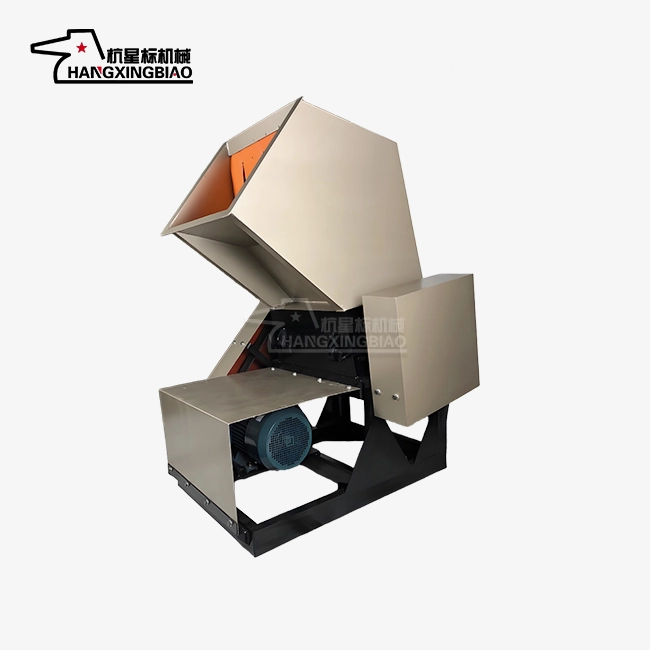

Industrial Solid Waste Shredder: Professional Crushing Solutions for Your Business

Are you struggling with mounting piles of waste materials in your facility? Our solid waste shredder delivers powerful, reliable crushing performance for diverse industrial applications. Whether you're processing plastic scraps, rubber waste, wood debris, or mixed municipal waste, this versatile machine transforms bulky materials into manageable pieces efficiently. With over 30 years of specialized manufacturing experience, Hangzhou Xingbiao Machinery Co., Ltd. has engineered the perfect solution for your waste reduction needs.

Why Choose Our Waste Shredding Equipment?

Unmatched Material Versatility

Unlike traditional crushers limited to single material types, our machines handle almost all non-metallic substances. From soft plastics and rubber to wood, paper, cloth, and organic waste - one machine covers your entire crushing requirements. This eliminates the need for multiple specialized units, saving you valuable floor space and investment costs.

Superior Build Quality and Durability

Your operations demand equipment that performs day after day. Our shredders feature:

- High-strength steel construction with stress-relief treatment

- Premium blade materials including SKD-11, D2 mold steel, and Cr12MoV alloys

- Vacuum heat treatment and deep cryogenic processing for extended blade life

- Precision-balanced components for smooth, vibration-free operation

Exceptional Processing Efficiency

Time is money in your business. Our optimized design delivers:

- 20% higher crushing efficiency compared to conventional models

- Processing rates from 50kg/h to 10 tons/h depending on model selection

- 24/7 continuous operation capability for demanding production schedules

- Consistent particle size output with 90%+ uniformity

Flexible Output Control for Every Application

Your solid waste shredder needs depend on your end-use requirements. Our machines offer precise particle size control through:

- Interchangeable screens ranging from 2mm to 100mm openings

- Adjustable rotor speeds for fine-tuning output characteristics

- Multiple blade configurations optimized for different materials

Whether you need coarse fragments for pretreatment or fine particles for recycling processes, you achieve the exact specifications required.

Cost-Effective Operation

Maximizing your return on investment matters. Our equipment delivers measurable savings through:

Reduced Tool Replacement Costs

High-hardness alloy blades (HRC55-60) provide 3,000-5,000 hours of service life. Plus, blades support 3-5 re-sharpening cycles, reducing replacement costs by 60% compared to standard carbon steel tools.

Lower Energy Consumption

Efficient motor-transmission combinations reduce power usage by 10-15%. Processing one ton of material typically requires only 8-12 kWh of electricity, keeping your operating expenses minimal.

Immediate Scrap Recovery

Process production waste instantly and blend it with virgin materials at ratios up to 50%. This recycling capability increases raw material utilization by 30-50%, potentially saving thousands annually in material costs.

Safety-First Design Philosophy

Worker protection remains paramount in industrial environments. Every unit incorporates:

- Fully enclosed crushing chamber with thick steel plate construction

- Anti-rebound baffles at feed openings

- Safety interlocks that automatically shut down power when chambers open

- Protective shields preventing material ejection during operation

Easy Maintenance for Maximum Uptime

Your equipment should work when you need it. We've engineered simple maintenance procedures:

- Quick-access panels for easy chamber cleaning

- Exposed maintenance points requiring no full disassembly

- Tool-free screen changes minimizing downtime

- Precision bearing systems with scheduled lubrication points

Complete Model Range for Every Need

From laboratory testing to large-scale recycling operations, we offer:

- Mobile units with wheels for flexible positioning

- Fixed installations for dedicated production lines

- Integrated systems linking with conveyors and downstream equipment

Your specific application determines the optimal configuration, and our engineering team helps you select the perfect match.

Contact Us

Ready to transform your waste management approach with a solid waste shredder?Contact our technical specialists at postmaster@xingbiaocrusher.com for personalized equipment recommendations and detailed specifications tailored to your specific applications.