Large-scale units of Industrial shredders link with granulators and conveyors to create complete automated production lines. Suitable for high-volume recycling facilities.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

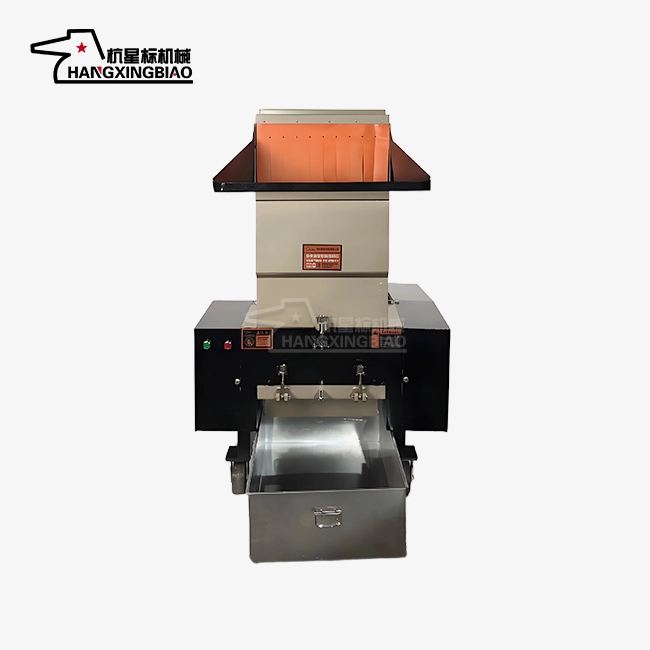

Industrial shredders

Industrial Shredders: Professional Plastic Crushing Solutions

Are you struggling with plastic waste management and material recycling in your production facility? Industrial shredders from Hangzhou Xingbiao Machinery offer the perfect solution for efficient plastic processing. Our specialized crushing equipment transforms waste materials into valuable resources. With 30 years of dedicated expertise in plastic processing technology, we deliver reliable shredding solutions that boost your productivity while reducing operational costs.

Why Choose Our Heavy-Duty Shredding Equipment?

Advanced Dual-Action Technology

Our machines feature a revolutionary "shear + impact" crushing process. This innovative design ensures optimal particle integrity while maintaining discharge uniformity above 90%. You won't need secondary screening, saving time and energy in your operations.

Superior Build Quality

Every unit features robust construction with high-strength steel welding. The main body undergoes stress relief treatment to prevent deformation during continuous operation. Core blades use premium materials including SKD-11, D2 mold steel, and Cr12MoV special steels for maximum durability.

Versatile Material Handling

Our equipment handles diverse plastic types effortlessly:

- Soft plastics (PE/PVC films, woven bags)

- Hard plastics (ABS/PC parts, thick-walled pipes)

- Foam materials (EPS/EVA buffer foam)

- Irregular shapes (bottles, trays, scraps)

Key Performance Features

Exceptional Processing Capacity

Our range of Industrial shredders covers all production scales. Small models process 50–500 kg per hour, while industrial units handle 1–10 tons hourly. Your facility can maintain 24-hour continuous operation without material accumulation or blockage.

Precision Size Control

Achieve perfect particle sizing through interchangeable screening nets (2-100mm options). Adjust tool speed or change blade sets to produce:

- Coarse fragments (5-50mm) for pretreatment

- Medium particles (2-12mm) for granulation recycling

Extended Tool Life

Premium alloy steel blades (HRC55-60 hardness) deliver 3000-5000 hours of crushing life. Tools support repeated grinding reuse up to 5 times, reducing replacement costs by 60% compared to standard carbon steel alternatives.

Energy Efficiency

Our optimized motor and transmission design reduces energy consumption by 10-15%. Processing one ton of plastic requires only 8-12 kWh, keeping your operating costs controllable.

Safety and Reliability Standards

Comprehensive Protection Design

Fully enclosed crushing chambers use thick steel plate construction. Anti-rebound baffles at feed inlets and external safety shields prevent material splash. Select models include "open-and-stop" interlocking devices for enhanced operator safety.

Stable Operation

Precision bearings and hardened gears minimize mechanical wear. Dynamic balance testing ensures vibration amplitude stays below 0.1mm. This reduces equipment failure rates by 40% compared to standard models.

Flexible Model Options

Mobile Units

Compact designs with universal wheels provide flexible movement between workstations. Perfect for smaller operations requiring versatility.

Fixed Installation

Medium-capacity units designed for permanent production line integration. Ideal for consistent processing requirements.

Automated Systems

Easy Maintenance and Operation

Quick-Access Design

Simple body construction allows rapid side panel removal for easy cleaning. This feature proves especially valuable when switching between different colored plastics to avoid contamination.

Streamlined Maintenance

Exposed key components (tools, bearings) enable daily inspection and lubrication without full machine disassembly. Maintenance time reduces by 50% compared to complex alternatives.

Built-In Anti-Winding Technology

Internal comb tooth design prevents jamming when processing fabrics, papers, films, and other fibrous materials.

Cost-Effective Recycling Benefits

Immediate Waste Processing

Transform production scraps into reusable materials instantly. Crushed materials blend with new materials at 3:7 to 5:5 ratios, increasing raw material utilization by 30-50%.

Significant Cost Savings

Companies save thousands annually on raw material procurement through efficient waste recycling. Your product investment pays for itself through reduced material costs.

Professional Support and Service

Our experienced engineering team provides comprehensive support throughout your equipment lifecycle. We offer:

- Professional selection consultation and custom solutions

- 24-hour response guarantee for customer inquiries

- Installation guidance and operator training

- Regular follow-up visits and spare parts supply

Contact Us

Ready to transform your plastic waste management with Industrial shredders? Contact our experts today at postmaster@xingbiaocrusher.com for personalized solutions that match your specific requirements and boost your operational efficiency.

Learn about our latest products and discounts through SMS or email