Our blade and chamber design boost efficiency over 20%, with optimized motors reducing energy use. Capacities range from 50 kg/h for small operations to 2,000 kg/h industrially.Your plastic water bottle crusher supports 24-hour continuous operation without performance degradation.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

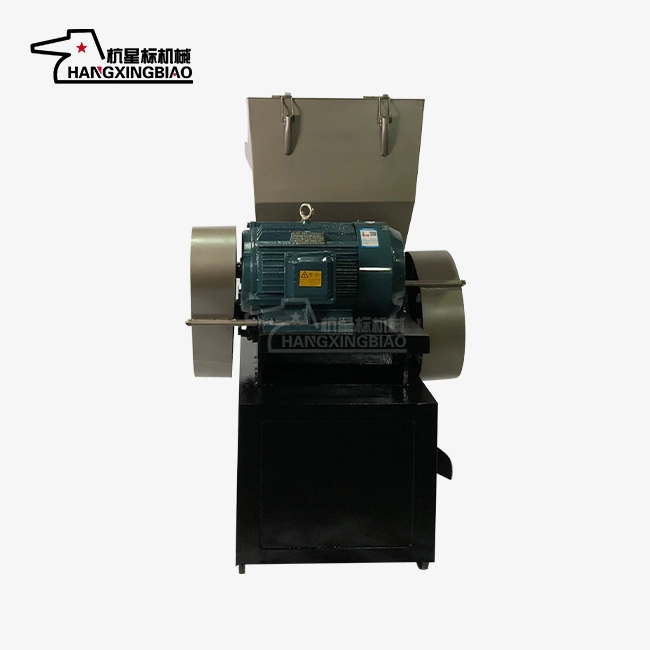

Plastic water bottle crusher

Plastic Water Bottle Crusher - Professional Recycling Solution

Looking for an efficient plastic water bottle crusher to streamline your recycling operations? Our premium crushing equipment transforms waste bottles into valuable reusable materials with exceptional efficiency. Designed specifically for processing plastic containers, our machines deliver consistent particle sizes while maintaining durability and safety standards. Whether you're managing small-scale operations or industrial-level recycling, our crushers provide the reliability you need for continuous production. With over 30 years of specialized experience, we understand exactly what makes bottle crushing equipment perform at its best.

Why Choose Our Bottle Crushing Equipment?

Superior Build Quality

Our crushers use welded, stress-relieved high-strength steel to prevent deformation. SKD-11 and Cr12MoV blades, treated with vacuum heat and cryogenic processes, provide maximum hardness, wear resistance, and 3,000–5,000 operating hours before replacement.

Outstanding Processing Efficiency

Precise Particle Control

You control final particle size through two adjustment methods:

Mechanical adjustment: Modify the gap between fixed and moving blades. Smaller gaps produce finer particles.

Screen adjustment: Replace outlet screens with different mesh sizes. Available options range from 2mm to 100mm openings.

This flexibility ensures your crushed bottles meet exact specifications for downstream processing.

Comprehensive Model Range

Standard Models

Perfect for general bottle crushing applications. These units handle various plastic types including PET, HDPE, and PP containers. The fully enclosed design minimizes noise levels below 75dB.

Heavy-Duty Industrial Units

Built for high-volume operations processing large containers and thick-walled bottles. Enhanced motor power and reinforced components ensure reliable performance under demanding conditions.

Customized Solutions

We design specialized equipment for unique requirements. Whether processing specific bottle types or integrating with existing production lines, our engineering team creates tailored solutions.

Advanced Safety Features

Your operators' safety is our priority. Every machine includes comprehensive protection systems:

- Fully welded crushing chambers prevent material spillage

- Anti-rebound baffles at feed openings block ejected particles

- Safety interlocks automatically shut down power when accessing internal components

- Overload protection prevents damage from metal contamination

The enclosed design effectively contains dust while reducing operational noise. This makes our equipment suitable for various workplace environments.

Cost-Effective Operation

Energy Efficiency

Our optimized transmission systems reduce power consumption by 10-15% compared to conventional crushers. Processing one ton of bottles typically requires only 8-12 kWh of electricity.

Extended Tool Life

Premium alloy cutting tools maintain sharpness far longer than standard carbon steel alternatives. The hardened edges can be resharpened 3-5 times, reducing replacement costs by 60%.

Immediate Material Recovery

Transform waste bottles directly into reusable flakes for manufacturing new products. The recycled material can blend with virgin plastics at 30-50% ratios, significantly reducing raw material costs.

Simple Maintenance Design

We've engineered our plastic water bottle crusher for easy servicing. Key maintenance points remain accessible without complete disassembly. The removable side panels allow quick chamber cleaning when switching between different plastic types.

Quick-change screen systems minimize downtime during particle size adjustments. Dynamic balancing of rotating components reduces vibration and extends bearing life.

Expert Technical Support

Our 20-engineer team offers full lifecycle support, collaborating with major companies to enhance designs. We respond to inquiries within 24 hours and provide installation guidance, operator training, and ongoing maintenance support.

Material Compatibility

Your crusher handles diverse bottle types without modification:

- Single-use water bottles

- Sports drink containers

- Juice and beverage bottles

- Household cleaning product containers

- Pharmaceutical bottles

The versatile design processes both rigid and flexible plastic containers effectively.

Contact Us

Ready to transform your plastic waste into valuable resources? Our plastic water bottle crusher delivers the performance and reliability your operation demands. Contact our technical team at postmaster@xingbiaocrusher.com to discuss your specific requirements and receive detailed specifications for the ideal crushing solution.

<

Learn about our latest products and discounts through SMS or email