Adjustable screens (2–100 mm), rotor speeds, and blade configurations enable precise particle sizes with over 90% uniformity, eliminating the need for secondary screening.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

commercial bone crusher

Commercial Bone Crusher: Heavy-Duty Equipment for Professional Processing

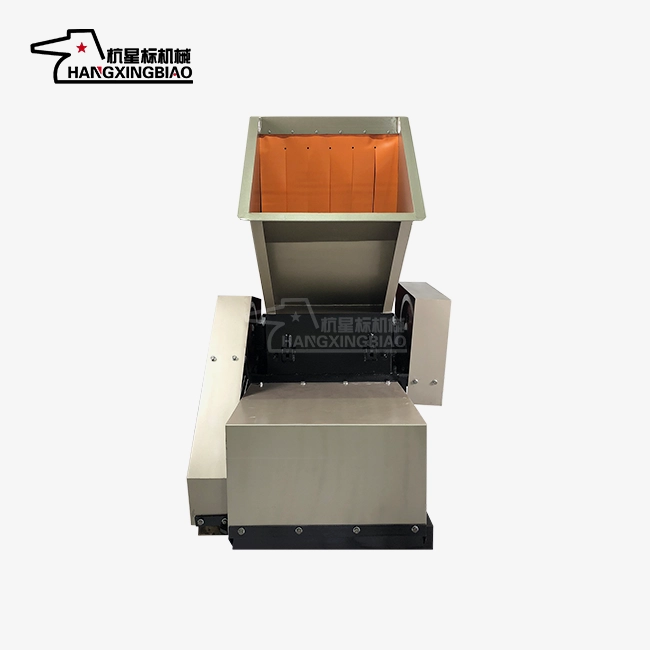

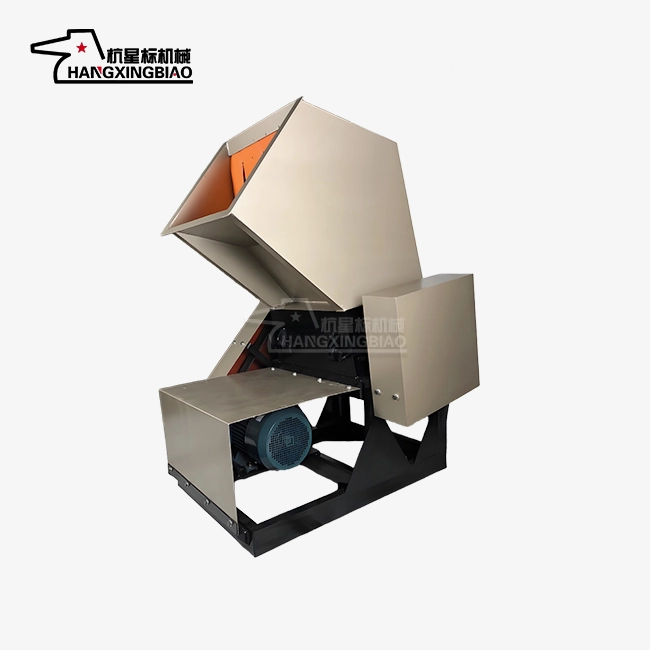

Are you looking for a reliable commercial bone crusher that delivers exceptional performance and durability? Your search ends here. At Hangzhou Xingbiao Machinery Co., Ltd., we understand that processing organic waste requires equipment that can handle tough materials while maintaining consistent output. Our industrial-grade bone crushing machines are designed to meet the demanding needs of restaurants, food processing plants, and waste management facilities across various industries.

Why Choose Our Heavy-Duty Bone Crushing Equipment?

Unmatched Engineering Excellence

Our bone crushing machines feature robust construction using high-strength steel plates with stress relief treatment. This ensures your equipment maintains peak performance during continuous operation. The main body undergoes precision welding and finishing processes that prevent deformation even under the heaviest workloads.

Superior Blade Technology: The heart of our equipment lies in its cutting system. We use premium materials including SKD-11/D2 mold steel and Cr12MoV special steels for our blades. Each blade undergoes vacuum heat treatment and deep cryogenic processing. This results in exceptional hardness ratings and outstanding wear resistance that extends operational life significantly.

Optimized Performance Features

High-Efficiency Design: Our unique blade layout and cavity structure increase processing efficiency by over 20% compared to standard equipment. The optimized motor matching reduces energy consumption while delivering superior crushing power.

Easy Maintenance: Quick-change screens and open-access design minimize downtime, allowing fast cleaning and rapid adjustments to achieve desired particle sizes.

Comprehensive Model Range

Heavy-Duty Industrial Models: Ideal for large-scale organic waste processing, these units operate continuously while maintaining consistent output quality.

Standard Processing Units: Ideal for medium-sized facilities requiring reliable daily processing capabilities. These models balance power with operational efficiency.

Custom Solutions: We design specialized equipment and collaborate with you to create solutions tailored to your unique operational requirements.

Advanced Safety and Reliability Features

Robust Safety Systems

Fully Enclosed Protection: Our commercial bone crusher crushing chambers feature thick steel plate construction with anti-rebound baffles at feed inlets. External safety shields effectively block material splash during operation.

Automatic Safety Controls: Select models include "open-and-stop" interlocking devices that automatically cut power when the chamber opens. This prevents accidents from operator errors.

Exceptional Durability

Precision Engineering: Our transmission systems use precision bearings and hardened gears with regular lubrication systems. This reduces mechanical wear and extends component life.

Balanced Operation: Key components including rotors and screening systems undergo dynamic balance testing. Vibration levels stay below 0.1mm, preventing parts loosening and reducing failure rates by 40%.

Flexible Processing Capabilities

Versatile Output Control

Energy-Efficient Operation

Our "efficient motor plus optimized transmission" design reduces energy consumption by 10-15% compared to traditional equipment. Processing one ton of material typically requires only 8-12 kWh of electricity.

Professional Support and Service

Expert Consultation

Our team of 20 senior engineers provides professional selection advice and customized solutions. We've established successful partnerships with major companies through our industry-university research collaborations.

Comprehensive Service Commitment

We respond to inquiries within 24 hours, providing installation guidance, training, follow-ups, and spare parts, ensuring professional support throughout your equipment’s operational life.

Easy Maintenance Design

Simple body design allows quick cavity side disassembly for thorough cleaning. Key maintenance points remain accessible without full machine disassembly. This reduces maintenance time by 50% compared to conventional designs.

Contact Us for Your Solution

For detailed specifications, custom quotes, or technical consultation, reach out to our experts at postmaster@xingbiaocrusher.com. Let us help you find the ideal commercial bone crusher solution for your operation today.

Learn about our latest products and discounts through SMS or email