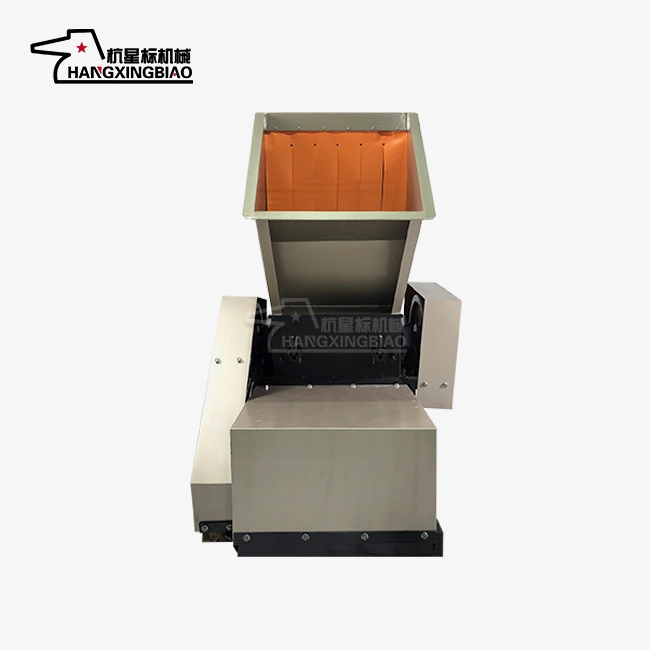

Our crushers feature high-strength, stress-relieved steel bodies for zero deformation during continuous operation. Precision-engineered SKD-11, D2, and Cr12MoV blades undergo vacuum heat and cryogenic treatment, achieving HRC 55–60. Blades last 3,000–5,000 hours and allow 3–5 re-sharpening cycles, cutting replacement costs by 60% versus standard carbon steel.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

plastic scrap crusher

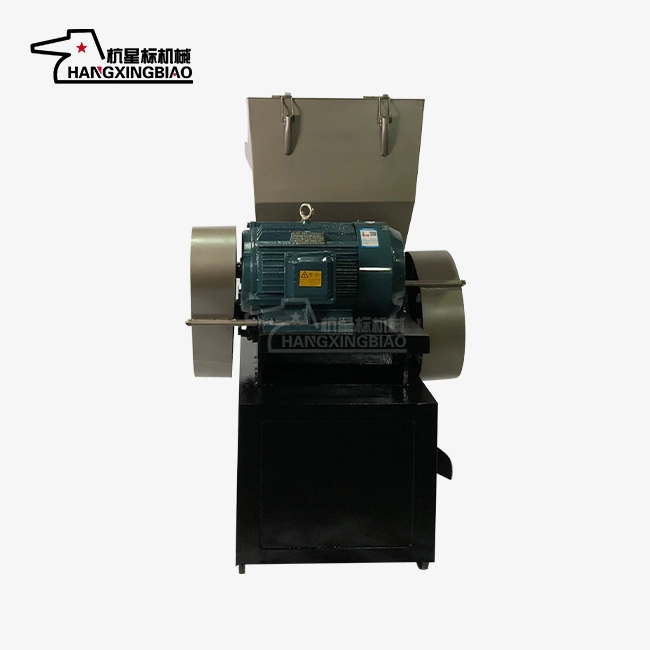

Heavy-Duty Plastic Scrap Crusher - Professional Recycling Equipment

Are you struggling with mounting plastic waste in your production facility? Our plastic scrap crusher delivers powerful, efficient crushing solutions for businesses of all sizes. Whether you're preparing infusion molding runners, expelled squander, or blended plastic materials, this strong machine changes your scrap into profitable reusable assets. With over 30 a long time of specialized involvement, Hangzhou Xingbiao Apparatus brings you cutting-edge pulverizing innovation that maximizes effectiveness whereas minimizing operational costs.

Superior Engineering for Maximum Performance

Versatile Material Processing Capabilities

Your plastic scrap crusher handles virtually any non-metallic material with ease. From soft PE films and PVC sheets to rigid ABS components and thick-walled pipes, this machine adapts to your specific needs.

The crusher handles EPS/EVA foam, irregular shapes, rubber, wood, paper, and textiles smoothly, eliminating clogging and the need for multiple specialized machines.

Precise Particle Size Control

Our flexible screening system uses interchangeable 2–100mm screens for precise particle control. Coarse 5–50mm fragments suit pre-treatment, while 2–12mm particles fit granulation. Over 90% uniformity eliminates secondary screening, and adjustable speed and blade settings ensure exact downstream specifications.

Exceptional Efficiency and Throughput

Our optimized edge format and chamber geometry increment pulverizing productivity by 20% compared to ordinary plans. Little models handle 50-500kg per hour, whereas mechanical units handle up to 10 tons hourly.

The equipment supports 24-hour continuous operation without performance degradation. Enhanced motor matching reduces energy consumption by 10-15%, requiring only 8-12 kWh to process one ton of plastic material.

Efficient processing translates directly to cost savings. Your plastic scrap crusher enables immediate recycling of production waste, reducing raw material purchases by 30-50%.

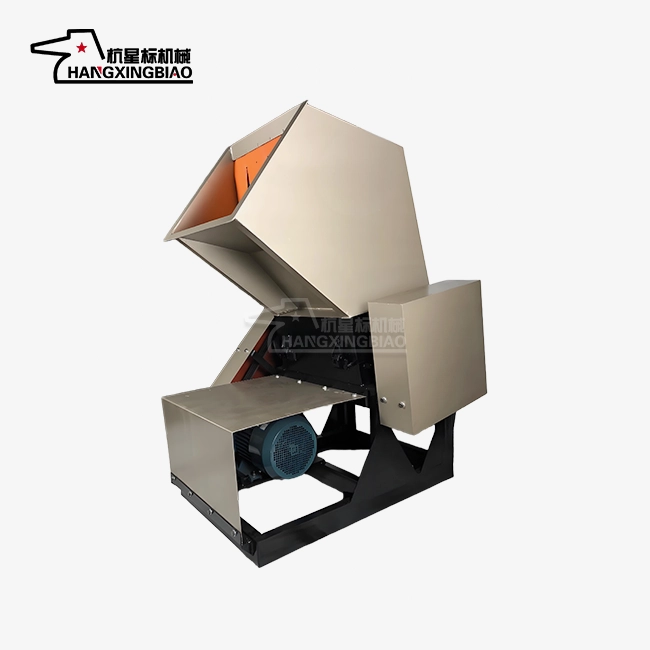

Safety-First Design Philosophy

Worker protection remains our top priority in every design decision. The crushing chamber features thick steel plate welding with comprehensive safety shielding around all moving components.

Anti-rebound baffles at the feed inlet prevent material ejection during operation. Selected models include interlock safety systems that automatically shut down power when access doors open.

This safety-conscious engineering protects your team while maintaining optimal productivity levels.

Complete Model Range for Every Application

Choose from portable units with all inclusive wheels for adaptable situating, settled establishments for devoted generation lines, or coordinates frameworks that connect with transports and granulators.

Laboratory-scale models begin at 50kg/hour capacity, scaling up to gigantic 10-ton/hour mechanical frameworks. Our designing group gives customized arrangements custom-made to your particular preparing requirements.

Every setup keeps up the same tall benchmarks for strength, security, and execution that characterize our brand.

Simplified Maintenance and Operation

Quick-change screen structures and open-design access panels minimize downtime during routine maintenance. Key components like blades and bearings remain easily accessible without full machine disassembly.

The simple body design allows rapid cavity cleaning when switching between different plastic types or colors. This prevents contamination while reducing changeover time by 50%.

Regular maintenance requires minimal specialized knowledge, keeping your product running smoothly with standard shop tools and basic mechanical skills.

Contact Us

Ready to transform your plastic waste with a plastic scrap crusher into profit?Contact us at postmaster@xingbiaocrusher.com for expert consultation and customized crushing solutions.

Learn about our latest products and discounts through SMS or email