Our “shear + impact” process, combined with optimized cavity structure and precise knife spacing, delivers over 90% uniformity with clean 2 mm discharge and no secondary screening. Anti-winding comb teeth prevent jamming, keeping operations smooth and reducing downtime.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

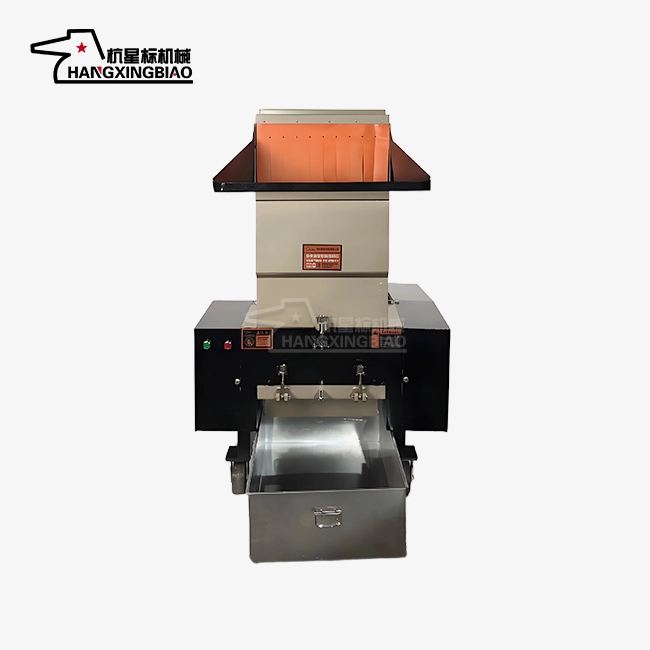

Bottle crusher

High-Performance Bottle Crusher for Efficient Plastic Recycling

Transform Your Plastic Waste Management Today

When you're dealing with plastic waste management, finding the right bottle crusher makes all the difference. Our progressed pulverizing arrangement changes plastic bottles into important reused materials rapidly and productively. Whether you run a little reusing operation or oversee a huge mechanical office, this item conveys uncommon execution that spares both time and money.

With over 30 a long time of specialized skill in plastic smashing innovation, we get it your special challenges. Our item highlights cutting-edge plan that handles different bottle sorts with ease. You'll appreciate the strong development and dependable operation that keeps your reusing line running easily day after day.

Why Our Crushing Technology Stands Out

Advanced Dual-Action Processing

Superior Blade Technology

We utilize SKD-11 and Cr12MoV edges treated with vacuum warm and cryogenic forms, conveying extraordinary hardness and over 3000 hours of benefit life. The multi-blade rotor and settled edges make exact shearing activity, guaranteeing reliably uniform molecule sizes.

Comprehensive Model Range for Every Need

Standard Capacity Models

Perfect for medium-scale operations, these units handle 50-500kg per hour. They're perfect for refreshment wholesalers, little reusing centers, and fabricating offices with direct bottle squander volumes.

Heavy-Duty Industrial Units

For large-scale operations, our industrial models handle 1-10 tons per hour. These powerhouses support continuous 24-hour operation while maintaining consistent output quality.

Customizable Solutions

Every operation is different. That's why we offer tailored configurations to match your specific requirements. Adjustable screen sizes from 2-100mm let you control final particle dimensions precisely.

Smart Design Features That Save You Money

Energy Efficiency

Our optimized motor and transmission design in the Bottle crusher reduces energy consumption by 10–15% compared to traditional equipment. Processing one ton of plastic bottles typically uses just 8–12 kWh of electricity.

Easy Maintenance

Quick-change screen structure and open design minimize maintenance time. Key components are easily accessible for inspection and lubrication without full machine disassembly. This reduces maintenance time by 50%.

Immediate Cost Recovery

Process waste bottles directly into reusable material. Mix crushed bottles with new plastic in ratios up to 50%. This increases raw material utilization by 30-50%, saving thousands in procurement costs annually.

Safety and Reliability First

Comprehensive Protection

Fully enclosed crushing chamber with thick steel plate construction ensures operator safety. The feed inlet includes anti-rebound baffles to prevent material ejection. Safety interlocks automatically cut power when access panels open.

Proven Durability

Precision orientation and solidified transmission components guarantee smooth operation. Energetic adjusting keeps vibration beneath 0.1mm, avoiding component releasing. Our gear appears 40% lower disappointment rates than standard models.

Complete Service Support

Our engineering team supports you from selection to installation, responding within 24 hours and providing full operator training. Professional setup guidance and regular follow-ups ensure peak performance, while our extensive spare parts inventory guarantees immediate availability.

Technical Specifications

Processing Capacity: 50kg/h to 10t/h depending on model

Particle Size Range: 2-100mm (adjustable via screen selection)

Blade Material: SKD-11/Cr12MoV alloy steel

Motor Options: Standard and high-efficiency configurations

Safety Features: Emergency stops, access interlocks, enclosed design

Start Maximizing Your Recycling Efficiency

Ready to transform your plastic bottle waste into valuable resources? Our bottle crusher technology delivers the performance and reliability your operation demands. Contact our technical team at postmaster@xingbiaocrusher.com for personalized consultation and detailed specifications tailored to your specific requirements.

Learn about our latest products and discounts through SMS or email