High-strength steel body with stress relief ensures stability. SKD-11 and Cr12MoV blades provide exceptional wear resistance and long service life.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

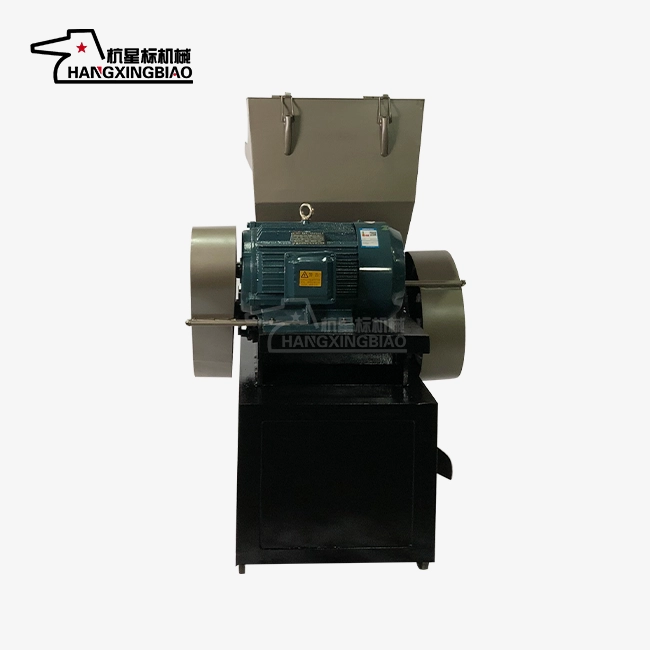

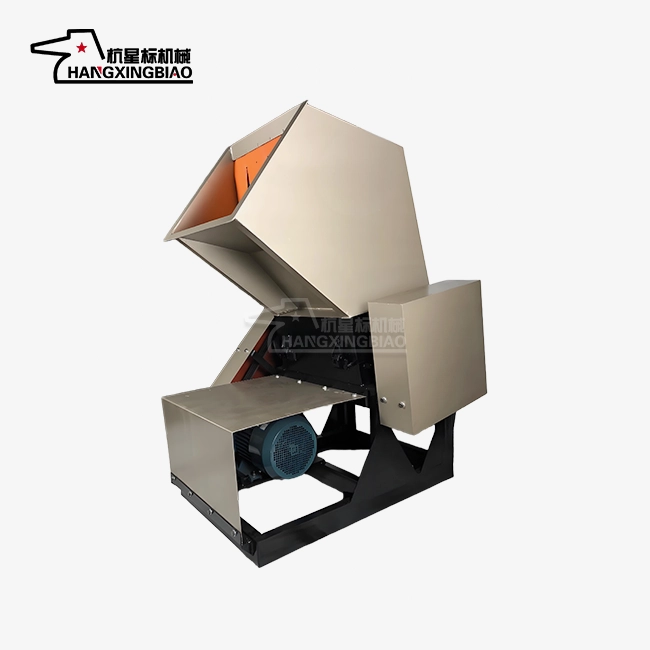

Industrial plastic shredder

Industrial Plastic Shredder - Efficient Plastic Recycling Solution

Are you struggling with plastic waste management in your facility? Our industrial plastic shredder delivers the perfect solution for your plastic processing needs. Designed and manufactured by Hangzhou Xingbiao Machinery Co., Ltd., this powerful equipment efficiently processes various plastic materials. Whether you handle soft films, hard plastic parts, or irregular shapes, this product adapts to your requirements. With over 30 years of specialization in plastic crushing technology, we understand your challenges. Our machines reduce waste volume by up to 80% while maintaining consistent output quality.

Why Choose Our Plastic Shredder?

Versatile Material Processing

Processes PE/PVC films, ABS parts, and foam efficiently. One robust shredder handles thin films to thick pipes, eliminating the need for multiple machines.

Superior Build Quality

Exceptional Efficiency

Optimized blade layout boosts efficiency 20%+. Energy-efficient motors reduce costs. Machines process 50 kg–10 t/hour, ensuring reliable performance for your production schedule.

Advanced Features That Matter

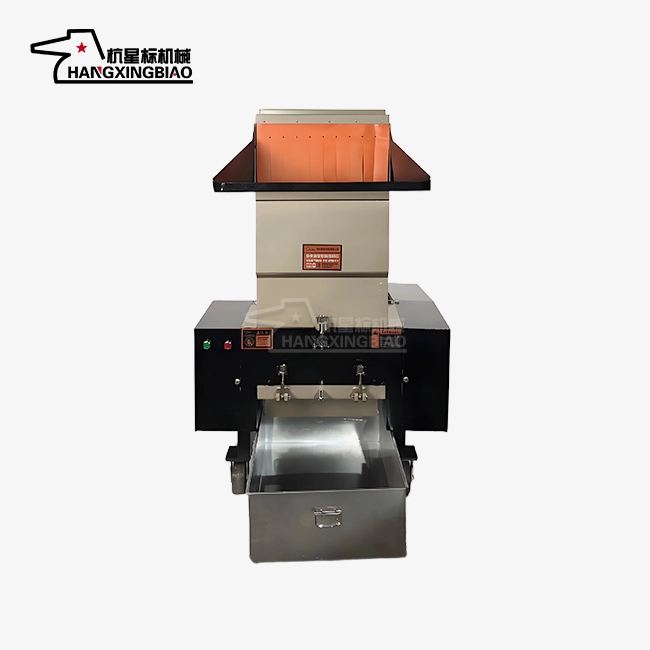

Precise Particle Control

Control output with interchangeable screens (2–100 mm). Achieve coarse fragments or fine particles for any downstream process with full flexibility.

Safety-First Design

Team safety is paramount. Emergency stops, protective shields, and fully enclosed chambers prevent spillage. Interlock systems automatically shut down when chambers open.

Low Maintenance Requirements

Quick-change screens and open design reduce downtime. Easy cleaning between materials and accessible components simplify routine inspections.

Cost-Effective Operation

Reduced Raw Material Costs

Recycle your production waste immediately with our industrial plastic shredder. Mix recycled material with new plastic at 30-50% ratios. This approach saves thousands in raw material purchases annually. Your return on investment becomes evident within months.

Energy-Efficient Performance

Our optimized motor and transmission system reduces energy consumption by 15%. Processing one ton of plastic requires only 8-12 kWh. Lower energy costs improve your bottom line significantly.

Durable Blade Technology

Premium alloy blades maintain sharpness for 3000-5000 operating hours. These blades support repeated sharpening, extending their useful life. Replacement costs are 60% lower than standard carbon steel alternatives.

Complete Product Range

Standard Models

Our standard crushers handle everyday plastic processing needs efficiently. These machines suit small to medium-scale operations perfectly. Compact designs fit existing production layouts easily.

Heavy-Duty Options

Large-scale operations require robust solutions. Our heavy-duty models process bulky items and high volumes. These machines deliver consistent performance under demanding conditions.

Custom Solutions

Unique applications need specialized equipment. We design custom solutions for specific material types and processing requirements. Our engineering team works closely with you throughout the development process.

Professional Support Services

Expert Consultation

Our experienced engineers help you select the right equipment. We analyze your specific requirements and recommend optimal solutions. Pre-sales support ensures you make informed decisions.

Installation and Training

We provide comprehensive installation guidance and operator training. Your team learns proper operation procedures and basic maintenance tasks. This knowledge maximizes equipment performance and longevity.

Ongoing Support

Our commitment extends beyond the initial sale. We offer 24-hour response times for technical inquiries. Regular follow-up visits ensure optimal equipment performance. Spare parts availability guarantees minimal downtime.

Environmental Benefits

Your commitment to sustainability matters. Our product supports circular economy principles by enabling efficient plastic recycling. Reduced waste going to landfills demonstrates environmental responsibility. Energy-efficient operation minimizes your carbon footprint.

Getting Started

Take the next step toward efficient plastic recycling. Reach out to us at postmaster@xingbiaocrusher.com for detailed information and pricing. Let our industrial plastic shredder become your trusted partner in sustainable plastic processing and waste reduction.

Learn about our latest products and discounts through SMS or email