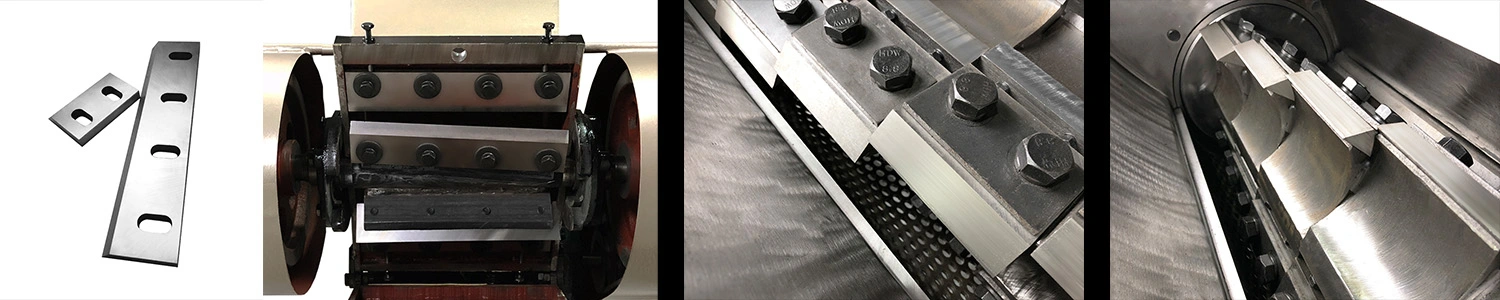

High-strength, stress-relieved steel prevents deformation. SKD-11/D2 and Cr12MoV blades with vacuum and cryogenic treatment deliver exceptional hardness, wear resistance, and extended service life, lowering operational costs.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

bone crusher machine

Premium Bone Crusher Machine for Industrial Material Processing

Are you looking for a reliable bone crusher machine that delivers exceptional performance and versatility? Our advanced product from Hangzhou Xingbiao Machinery Co., Ltd. revolutionizes material processing with cutting-edge technology. With 30 years of specialized expertise in crushing equipment manufacturing, we provide robust solutions that handle various non-metallic materials efficiently. This innovative product ensures superior durability and cost-effectiveness for your business operations.

Why Our Industrial Crushing Equipment Stands Out

Our manufacturing excellence comes from three decades of focused research and development. We've built our reputation on delivering single-category excellence through continuous innovation and improvement.

Advanced Engineering Team

Our 20 senior engineers work tirelessly to enhance crushing technology. We collaborate with industry leaders like Nongfu Spring and KFC to ensure our equipment meets real-world demands. This partnership approach helps us understand your specific processing challenges.

Superior Build Quality

Comprehensive Material Processing Capabilities

Our bone crusher machine breaks traditional limitations of single-material adaptation. You can efficiently process almost all non-metallic materials except metal and rock.

Versatile Material Handling

- Plastic components and rubber materials

- Wood, paper, cloth, and foam products

- Traditional Chinese medicine and grain processing

- Feed preparation and non-corrosive chemicals

- Fruit and vegetable residues

- Waste cartons and packaging materials

Whether your materials are block-shaped, flaked, fibrous, or irregularly formed, our equipment handles them reliably. The discharge particle size adjusts flexibly through interchangeable screens, with conventional coverage from 2-50mm.

Advanced Design Features

High-Efficiency Performance

Unique blade layout and cavity design boost efficiency 20%+. Optimized motors cut energy use. Small units handle 50–500 kg/hour, industrial 1–10 t/hour, supporting 24-hour continuous operation.

Precision Control Systems

You achieve accurate particle size control by changing screening nets with different pore sizes (2-100mm options). Adjust tool speed or change knife sets for flexible production requirements.

- Coarse fragments (5-50mm) for pretreatment applications

- Medium particles (2-12mm) for granulation and injection recycling

- Particle uniformity exceeds 90% without secondary screening

Durability and Cost Efficiency

Premium Tool Materials

Core tools of SKD11, high-speed steel, and Cr12MoV reach HRC 55–60, lasting 3,000–5,000 hours. Regrindable 3–5 times, they cut replacement costs 60% versus carbon steel, reducing wear parts usage.

Energy-Efficient Operation

Our efficient motor and optimized transmission structure in the bone crusher machine reduces energy consumption by 10–15%. Processing one ton of material requires only 8–12 kWh of electricity.

Safety and Reliability Standards

Comprehensive Safety Features

Thick steel chambers with anti-rebound baffles and external shields ensure durability and operator safety. "Open and stop" interlocks automatically cut power when chambers open, preventing accidental injuries.

Stable Operation Design

Precision bearings and hardened gears with regular lubrication reduce wear. Dynamic balance testing keeps vibration ≤0.1 mm, preventing loosening and lowering equipment failure rates by 40%.

Flexible Model Options

Customizable Configurations

- Mobile units with universal wheels for flexible station movement

- Fixed medium-sized models for permanent production lines

- Integrated large systems linking with granulators and conveyor belts

Coverage spans from laboratory testing (50kg/h) to large-scale recycling operations (10t/h).

Easy Maintenance Design

Simple body allows quick cavity disassembly for easy cleaning, especially when switching colors. Exposed maintenance points enable daily inspection and lubrication, reducing maintenance time by 50% versus conventional equipment.

Professional Service Support

Ready to enhance your material processing efficiency? Contact our expert team at postmaster@xingbiaocrusher.com for personalized consultation and discover how our bone crusher machine can transform your operations today.

Learn about our latest products and discounts through SMS or email