Core cutting components use SKD-11 and Cr12MoV steels hardened to HRC55–60 for long service life, delivering 3,000–5,000 hours of performance. Each blade supports 3–5 resharpenings, reducing replacement costs by 60%.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

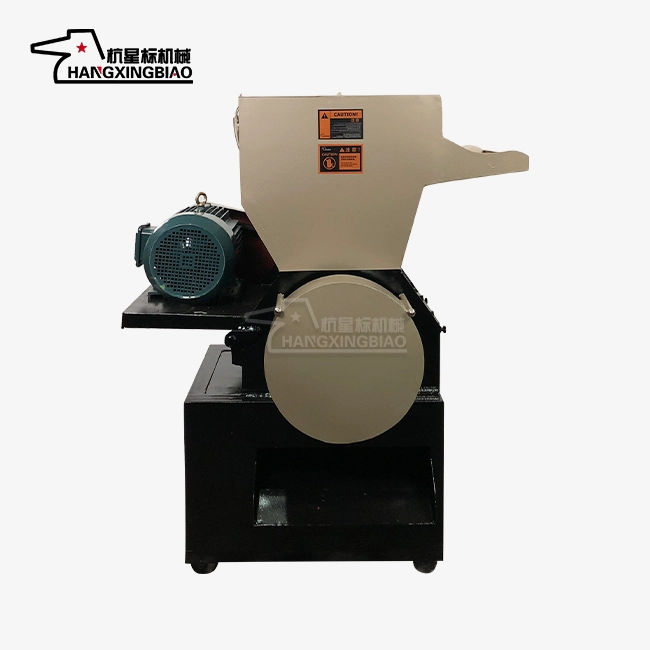

pipe crusher machine

Pipe Crusher Machine: Professional Plastic Processing Solution

Are you struggling with efficient plastic pipe recycling? Our industrial-grade pipe crusher machine delivers exceptional performance for processing plastic pipes of all sizes. This progressed hardware changes squander channels into profitable reusable materials, making a difference producers diminish costs whereas supporting natural supportability. Your generation line merits solid apparatus that handles everything from PVC channels to complex plastic tubing frameworks effectively.

Why Choose Our Product?

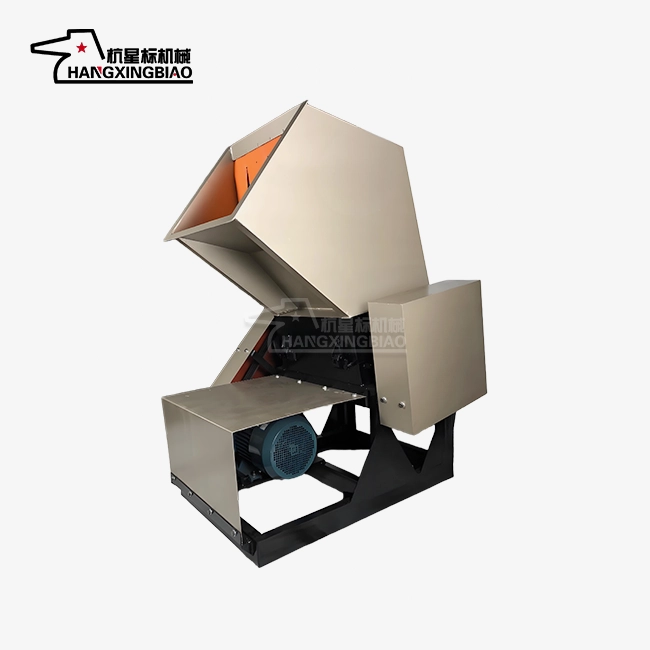

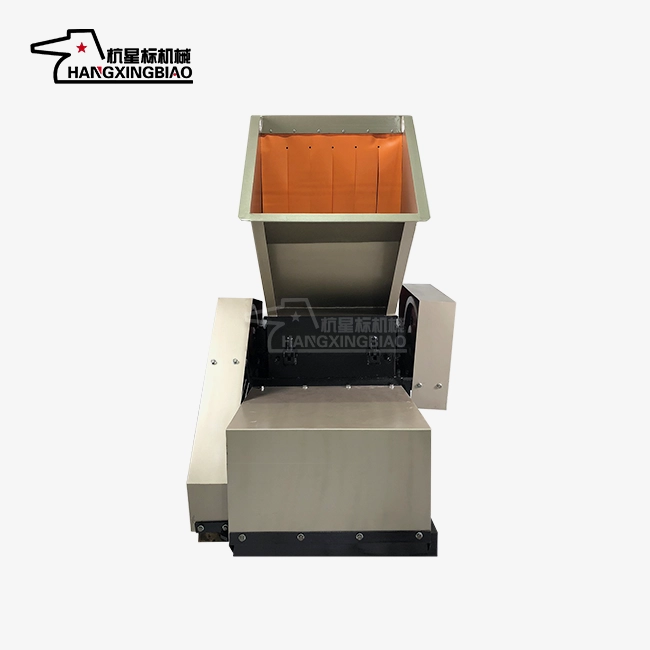

Superior Engineering Design

Our crushing equipment features robust construction using high-strength steel plates with stress relief treatment. This ensures zero deformation during continuous operation. The main components undergo vacuum heat treatment, delivering exceptional durability for demanding industrial applications.

You'll appreciate the optimized blade configuration that increases processing efficiency by over 20%. The intelligent cavity design maximizes material flow while minimizing energy consumption. Your operational costs stay low while productivity remains consistently high.

Wide Material Compatibility

This versatile machine handles diverse plastic materials beyond traditional pipes. You can process:

- PVC and PE pipes of various diameters

- Rigid plastic tubing systems

- Flexible hose materials

- Mixed plastic waste streams

- Industrial pipe offcuts

The equipment adapts seamlessly to different material densities and compositions. You won't need multiple machines for varied processing requirements.

Precise Particle Control

Our adjustable screens (2–100 mm) deliver over 90% uniform particle uniformity, removing the need for secondary processing. Easily switch between coarse and fine outputs, while quick-change screens minimize downtime during size adjustments.

Technical Performance Features

High-Capacity Processing

Our models deliver impressive throughput rates:

- Compact units: 50-500kg per hour

- Industrial models: 1-10 tons per hour

- Continuous 24-hour operation capability

Your production schedules stay on track with reliable, consistent performance. The pipe crusher machine maintains steady output even during extended operating periods.

Advanced Blade Technology

Energy-Efficient Operation

Our optimized motor and transmission design reduces power consumption by 10-15% versus conventional equipment. Processing one ton of material requires only 8-12 kilowatts, keeping operational expenses manageable.

You'll see immediate savings on electricity bills while maintaining full processing capacity.

Safety and Reliability Standards

Comprehensive Protection Systems

Every unit incorporates fully enclosed safety features. Thick steel plate construction surrounds the crushing chamber, while anti-rebound baffles protect the feed inlet. External safety shields prevent material spillage during operation.

Advanced models include interlock systems that automatically cut power when access doors open. This prevents accidental injuries during maintenance procedures.

Minimal Maintenance Requirements

The simplified design provides easy cavity access and maintenance, cutting service time by 50%. Precision bearings, hardened gears, and dynamic balance testing keep vibration under 0.1 mm, ensuring smooth operation and reducing failure rates by 40%.

Flexible Model Options

Customizable Configurations

Choose from three primary categories:

Mobile Units: Compact designs with universal wheels for flexible positioning across multiple workstations.

Fixed Installations: Medium-capacity models for permanent production line integration.

Integrated Systems: Large-scale units that connect with granulators and conveyors for complete automation.

We provide custom engineering for unique processing requirements. Your specific application needs receive dedicated technical attention.

Complete Service Support

Our engineering team supports you from selection to operation with expert installation guidance and operator training. We provide 24-hour technical response, regular follow-ups, and full spare parts availability to maintain peak performance.

Contact Us

Ready to transform your pipe crusher machine plastic processing capabilities?Contact our technical specialists at postmaster@xingbiaocrusher.com for detailed specifications and custom recommendations. We'll help you select the perfect equipment configuration for your specific requirements.

Learn about our latest products and discounts through SMS or email