Our wood crusher delivers 50–2000 kg/h capacity with reliable 24-hour operation. SKD-11 and D2 blades, treated through vacuum and cryogenic processes, provide exceptional hardness and wear resistance, lasting far longer than standard options.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

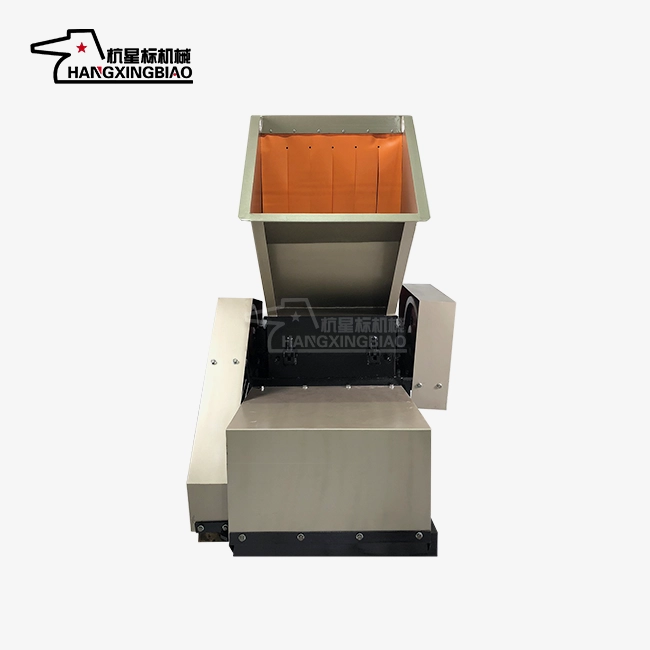

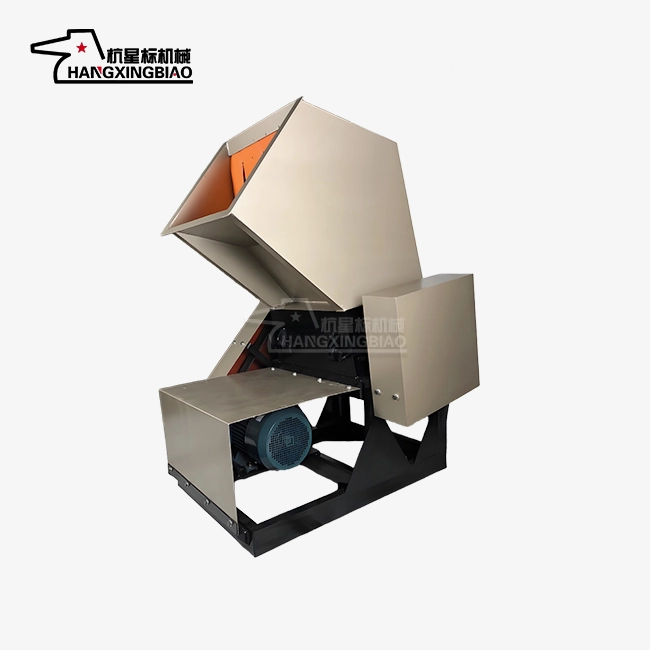

small wood crusher machine

Small Wood Crusher Machine - Efficient Wood Processing Solution

Looking for a reliable small wood crusher machine for your wood processing needs? You've found the culminate arrangement. Our item is planned to handle different wood materials with remarkable proficiency and solidness. Whether you're preparing wood chips, sawdust, or bigger wood pieces, this machine conveys steady comes about each time. Built with accuracy designing and high-quality materials, our crusher changes wood squander into important resources.

Exceptional Performance You Can Count On

Superior Build Quality

Every component is built to last. The main body uses high-strength steel plates with stress relief treatment. This prevents deformation during long-term operation. The robust construction ensures years of reliable service.

Our engineers designed an optimized motor matching system. This reduces energy consumption by 10-15% compared to traditional equipment. You'll process more material while using less power.

Advanced Features for Maximum Efficiency

The small wood crusher machine includes several innovative features. The quick-change screen structure allows easy particle size adjustment. You can switch between different screen sizes from 2mm to 100mm. This flexibility meets various processing requirements.

Safety comes to begin with with a completely encased chamber and over-burden assurance that stops the machine when difficult objects enter. The low-noise engine works at ≤75 dB, ensuring gear, amplifying benefit life, and guaranteeing a calmer, more comfortable workspace.

Easy Operation and Maintenance

The open plan permits quick cleaning and support, cutting downtime by 50%. Key components are effectively available, and the detachable side board empowers exhaustive cleaning between wood sorts to keep up immaculateness and anticipate defilement.

Versatile Applications

Your wood crusher handles various materials effectively. Process softwoods, hardwoods, bamboo, and wood composites. The machine adapts to different moisture content levels. You can process both fresh and dried wood materials.

Common applications include:

- Wood waste recycling

- Biomass preparation

- Fuel pellet production

- Composite material preparation

- Laboratory sample preparation

Models to Fit Your Needs

We offer multiple configurations to match your specific requirements. Choose from mobile, fixed, or integrated models. Mobile units include universal wheels for easy positioning. Fixed models provide stable floor installation for production lines.

Our small wood crusher machine processing range covers laboratory testing (50kg/h) to medium-scale production (2000kg/h). Each model maintains the same quality standards and performance reliability.

Proven Durability

Core cutting tools use premium alloy materials including high-speed steel and Cr12MoV. Tool hardness reaches HRC55-60. This provides 3000-5000 hours of crushing life under normal conditions.

The tools support repeated grinding and reuse. You can polish them 3-5 times before replacement. This reduces operating costs by 60% compared to ordinary carbon steel tools.

Professional Support and Service

Hangzhou Xingbiao Machinery Co., Ltd. has 30 years of crushing equipment experience. Our 20 senior engineers offer full technical support with 24-hour responses, installation guidance, operator training, regular follow-ups, and reliable spare parts availability.

The precision bearing and hardened gear transmission system requires minimal maintenance. Regular lubrication keeps everything running smoothly. Dynamic balance testing ensures vibration amplitude ≤0.1mm.

Investment in Quality

Ready to enhance your small wood crusher machine wood processing capabilities?Contact our team at postmaster@xingbiaocrusher.com for detailed specifications and pricing. We'll help you select the perfect configuration for your specific needs and production requirements.

Learn about our latest products and discounts through SMS or email