Our stress-relieved steel structure prevents deformation during long operation. Premium SKD-11/D2 and Cr12MoV blades, treated through vacuum and cryogenic processes, deliver high hardness and long life. The optimized blade layout boosts efficiency by 20%, while motor matching cuts energy use for lower operating costs.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Wood shredder

Wood Shredder: Professional Industrial Wood Processing Solutions

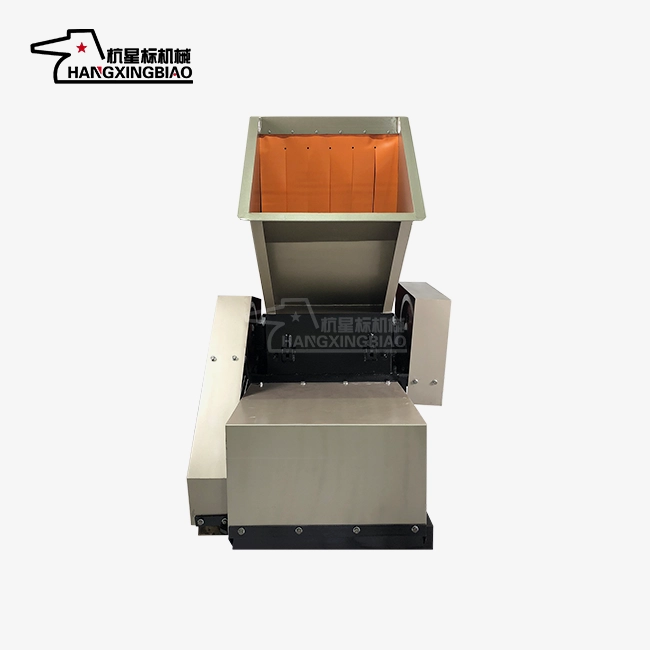

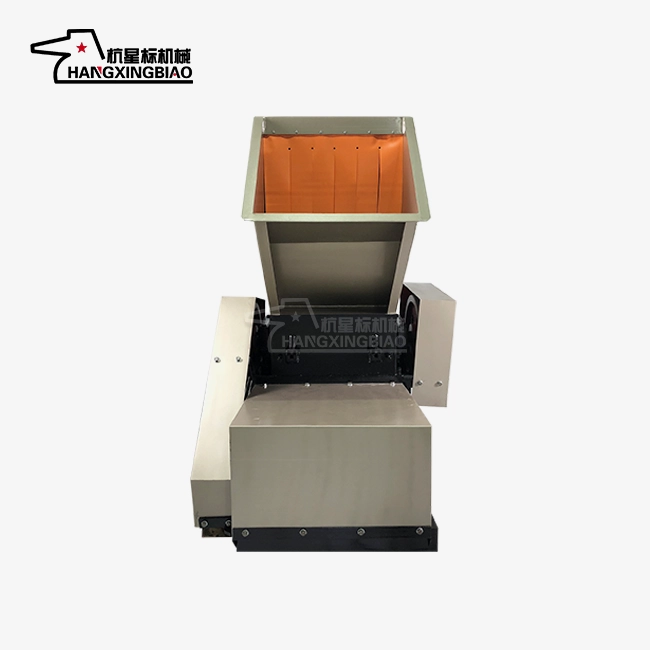

Are you looking for an efficient solution to process wood waste, branches, or timber scraps? Our wood shredder represents 30 years of engineering excellence from Hangzhou Xingbiao Machinery Co., Ltd. This versatile machine efficiently processes various wood materials, from small branches to large timber pieces. Whether you need to handle sawdust, wood chips, or bulky wood waste, our product delivers consistent results. Built with robust construction and precision engineering, this equipment transforms your wood processing challenges into streamlined operations.

Advanced Design for Superior Performance

Versatile Material Processing Capabilities

This versatile equipment processes wood and various non-metallic materials, including plastic, rubber, paper, cloth, foam, and organic waste. It handles blocks, flakes, fibers, and irregular shapes with stable performance. Adjustable screens provide 2–50mm output. Capacity ranges from 50–500kg/h to 1–10t/h with continuous operation.

Precision Control and Customization

Your specific particle size requirements are easily achieved. Simply change screening nets with different pore sizes (2-100mm options available). Adjust blade speed or modify knife sets for different output specifications.

Produce coarse fragments (5-50mm) for pretreatment applications. Create medium particles (2-12mm) for specialized processing needs. Particle uniformity exceeds 90% consistency without secondary screening requirements.

Cost-Effective Operations

The wood shredder delivers immediate cost benefits through efficient waste processing. Transform wood waste into valuable materials for various applications. Reduce disposal costs while creating revenue streams from processed materials.

Tool durability lowers maintenance costs. Alloy steel components with HRC55-60 hardness deliver 3,000–5,000 hours of service. Each tool supports 3–5 sharpening cycles, reducing replacement expenses by 60% and keeping long-term operational costs controlled.

Energy Efficiency and Safety Features

Our optimized motor and transmission system cuts energy use by 10–15%, needing only 8–12 kWh per ton. The thick-steel crushing chamber and anti-rebound baffles enhance safety, while exterior shields prevent material splash. Selected models include “open-and-stop” interlocks that automatically cut power during chamber access.

Easy Maintenance and Reliability

Our precision bearings and hardened gears with regular lubrication ensure low wear and high reliability. Dynamic balance keeps vibration below 0.1mm, reducing failure rates by 40%. The simple body design allows quick cavity access and easy cleaning, with exposed maintenance points requiring no full disassembly.

Complete Model Range

Choose from mobile units with universal wheels for flexible positioning. Fixed models provide floor installation for dedicated production lines. Integrated systems link with conveyors for automated processing chains.

Coverage spans from laboratory testing (50kg/h) to large-scale operations (10t/h). Our engineering team provides customized solutions for unique application requirements.

Professional Support and Service

Our 20-engineer team delivers decades of expertise supported by strong industry partnerships. We respond to inquiries within 24 hours. Installation guidance, operator training, follow-up support, and ample spare parts ensure optimal performance and minimal downtime.

Transform Your Wood Processing Today

Ready to upgrade your wood processing capabilities? Our wood shredder combines proven engineering with advanced features for superior results. Contact our team at postmaster@xingbiaocrusher.com for detailed specifications and customized solutions. Experience the difference that three decades of specialized manufacturing excellence makes in your operations.

Learn about our latest products and discounts through SMS or email