Processing 50 kg–2 t/hour, our machines run 24/7 with unique blade layout boosting efficiency 20%, immediately improving workflow.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

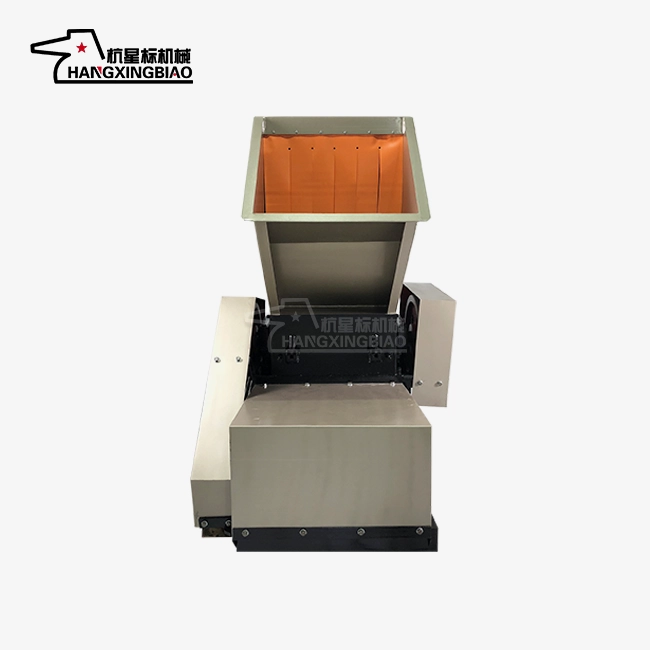

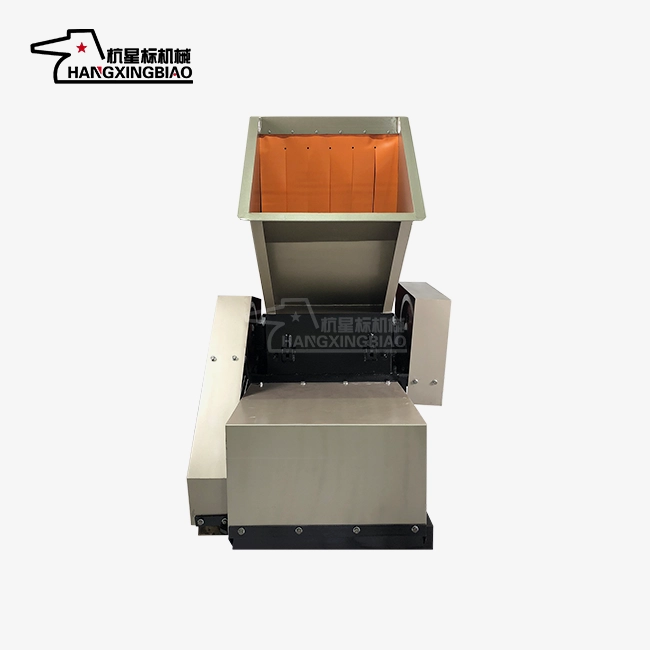

Plastic bottle crusher

Plastic Bottle Crusher: Professional Solution for Efficient Recycling

Are you looking for an efficient way to process plastic waste? Our plastic bottle crusher is designed to transform your waste materials into valuable resources. With over 30 years of specialized experience at Hangzhou Xingbiao Machinery Co., Ltd., we've perfected the art of plastic crushing technology. Our machines efficiently process small bottles to large containers, reducing waste volume up to 90% and producing consistent particle sizes ideal for recycling.

Why Choose Our Bottle Crushing Equipment?

Superior Build Quality You Can Trust

Our machines use stress-relieved high-strength steel and SKD-11/D2 blades with vacuum and cryogenic treatment, ensuring deformation-free, long-lasting, and highly durable operation.

Impressive Processing Capabilities

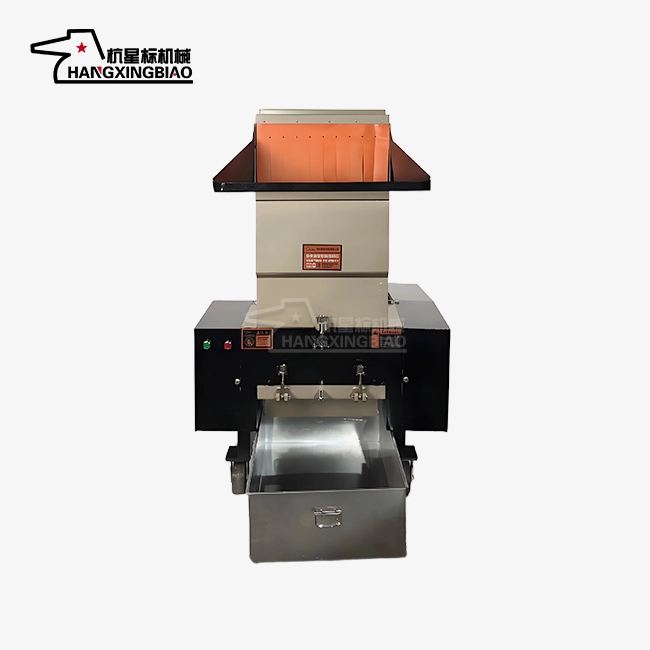

Smart Safety Features

Safety-focused design includes overload protection, fully enclosed chambers that block dust, reduce noise below 75 dB, and prevent damage while keeping operators safe.

Versatile Applications for Every Industry

Beverage Industry Solutions

Process PET bottles, caps, and labels efficiently. Our machines handle various bottle sizes from small water bottles to large juice containers. The adjustable screening system produces uniform particles perfect for recycling into new bottles.

Manufacturing Waste Management

Transform production waste into valuable raw material. Crush runner material, defective parts, and trim waste immediately after production. Mix the crushed material with virgin plastic at ratios up to 50:50 for cost-effective manufacturing.

Recycling Center Operations

Large-scale operations benefit from our high-capacity Plastic bottle crusher models. Process mixed plastic waste streams efficiently. The quick-change screen system allows easy switching between different particle sizes without stopping production.

Advanced Features That Make the Difference

Precision Particle Control

Choose from screening meshes ranging from 2mm to 100mm. This flexibility ensures you get exactly the particle size needed for your application. Over 90% particle uniformity eliminates the need for secondary screening operations.

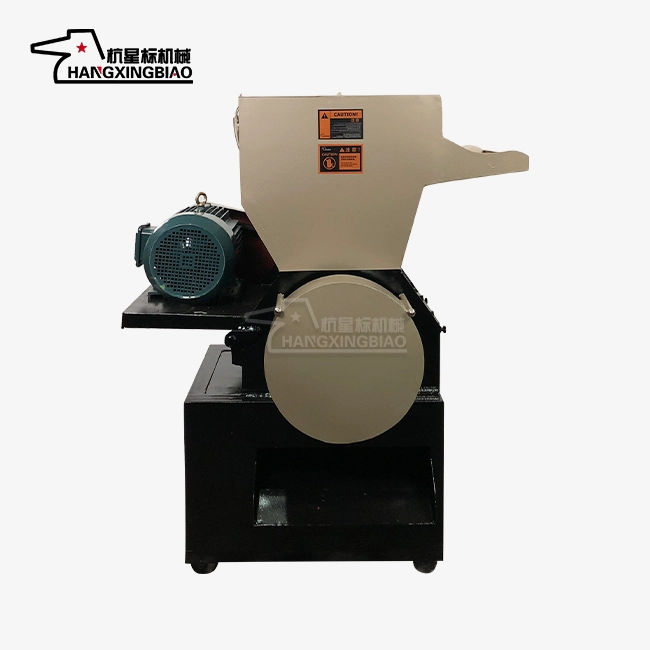

Energy Efficient Operation

Our optimized motor design reduces power consumption by 10-15% compared to conventional crushers. Processing one ton of plastic typically uses only 8-12 kWh of electricity. This translates to significant cost savings over time.

Easy Maintenance Design

Quick-access panels make cleaning and maintenance simple. Key components like blades and bearings are easily accessible without full machine disassembly. This reduces maintenance time by 50% compared to traditional designs.

Multiple Models for Every Need

Compact Mobile Units

Perfect for smaller operations requiring flexibility. These wheeled units move easily between workstations. Ideal for processing 50-500kg per hour in workshops or small facilities.

Standard Fixed Models

Medium-capacity machines designed for dedicated production lines. These offer the best balance of size and processing power. Perfect for most manufacturing and recycling applications.

Heavy-Duty Industrial Systems

Large-scale operations require robust equipment. Our industrial models process 1-10 tons per hour continuously. These can integrate with conveyor systems and granulators for complete automation.

Cost-Effective Operation Benefits

Reduced Raw Material Costs

Immediate recycling of production waste saves thousands annually on raw material purchases. The plastic bottle crusher enables efficient reuse of materials that would otherwise be discarded. Your material utilization improves by 30-50% through effective waste processing.

Long-Term Blade Life

Premium alloy blades last 3000-5000 hours of operation. They can be resharpened 3-5 times before replacement. This reduces blade costs by 60% compared to standard carbon steel alternatives.

Minimal Downtime Requirements

Precision-balanced components reduce vibration to under 0.1mm. This prevents premature wear and component loosening. Equipment failure rates drop by 40% compared to standard models.

Professional Support Every Step

Ready to transform your plastic waste into profit? Contact our experts at postmaster@xingbiaocrusher.com for personalized recommendations. We'll help you select the perfect Plastic bottle crusher solution for your specific requirements.

Learn about our latest products and discounts through SMS or email