For 30 years, Hangzhou Xingbiao Machinery has specialized in plastic crushing, supported by 20 senior engineers and trusted by brands like Nongfu Spring and KFC.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

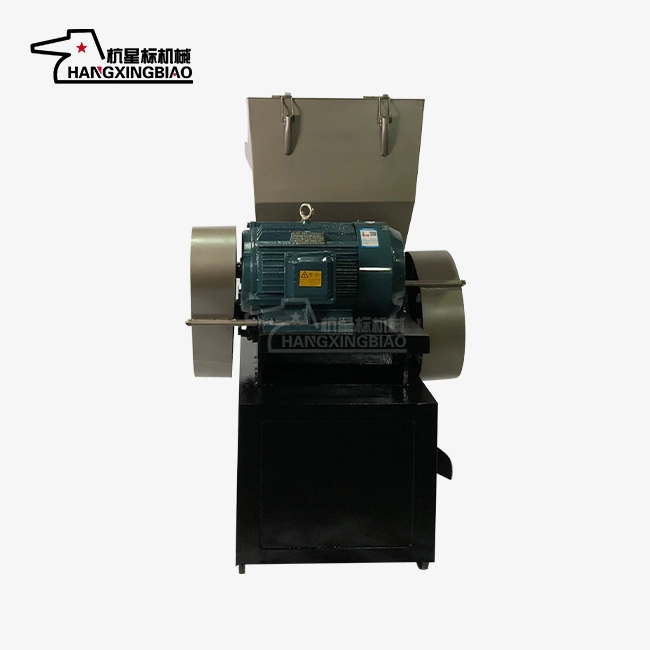

compact plastic shredder

Compact Plastic Shredder - Efficient Plastic Waste Processing Solution

Looking for a reliable compact plastic shredder to handle your plastic waste efficiently? You've come to the right place. Our product combines advanced engineering with user-friendly design to deliver outstanding performance for businesses of all sizes. With processing capacities ranging from 50kg/h to 2000kg/h, this versatile machine handles everything from soft films to rigid plastic parts, making it perfect for injection molding facilities, recycling centers, and manufacturing plants.

Why Choose Our Small-Scale Plastic Crusher?

Proven Engineering Excellence

Built to Last Performance

Your production can't afford downtime. That's why we construct our plastic size reduction equipment using high-strength steel plates with stress relief treatment. The main body stays perfectly aligned even after years of continuous operation. Our cutting blades use premium SKD-11 and D2 mold steel, treated with vacuum heat treatment and deep cryogenic processing for maximum durability.

Comprehensive Material Handling Capabilities

Versatile Plastic Processing

Whether you're dealing with soft PE films, rigid ABS parts, or foam materials, our plastic granulator handles them all. You won't need multiple machines for different materials. Switch between processing woven bags, plastic bottles, thick-walled pipes, or manufacturing scraps without equipment changes.

Precise Size Control

Easily control output by swapping 2–100mm screens to achieve desired particle sizes, from coarse 5–50mm to fine 2–12mm. Over 90% uniformity removes the need for secondary screening.

Cost-Effective Operation

Immediate Scrap Recycling

Transform waste into profit instantly with the compact plastic shredder. Process runner materials, rejected parts, and production scraps immediately. Mix crushed material with virgin plastic at 30-50% ratios to reduce raw material costs significantly. Many customers save thousands annually on material

Energy Efficient Design

Our optimized motor and transmission system reduces energy consumption by 10-15% compared to traditional units. Process one ton of plastic using only 8-12 kWh of electricity. Lower operating costs mean faster return on investment.

Long-Lasting Cutting Tools

Premium alloy blades (HRC55-60 hardness) deliver 3000-5000 hours of crushing life with ordinary plastics. When sharpening is needed, blades can be reground 3-5 times before replacement. This extends tool life and reduces maintenance costs by 60% compared to standard carbon steel options.

Safety and Environmental Features

Enclosed Operation Design

Fully enclosed crushing chamber with thick steel plate construction contains noise and debris. Operating noise stays below 75dB, suitable for workshop environments. Anti-rebound baffles and safety shields protect operators during operation.

Automatic Protection Systems

Built-in overload protection detects metal contaminants or jams automatically. The system shuts down and sounds an alarm before damage occurs. "Open-and-stop" interlocking prevents accidental startup when accessing the chamber.

Flexible Configuration Options

Multiple Size Options

Choose from mobile units with wheels for flexible positioning, fixed floor-mounted models for dedicated production lines, or integrated systems that connect with conveyors and granulators. Processing capacities span from 50kg/h laboratory units to 10-ton industrial systems.

Easy Maintenance Access

Quick-change screens and open chamber access simplify cleaning between color changes. Easy maintenance access cuts service time by 50%, ensuring efficient operation.

Quality Assurance and Support

Precision Manufacturing

Every rotor and screen undergoes dynamic balance testing. Vibration amplitude stays below 0.1mm to prevent component loosening. Precision bearings and hardened gears with regular lubrication points reduce mechanical wear. Equipment failure rates are 40% lower than standard models.

Comprehensive Service Coverage

Our engineers help you choose the right model, provide installation training, and ensure smooth operation with fast support and spare parts availability.

Models for Every Application

Ready to improve your plastic waste processing efficiency? Contact our team at postmaster@xingbiaocrusher.com for expert guidance on selecting the perfect compact plastic shredder for your application. Let's discuss how our proven technology can enhance your operations.

Learn about our latest products and discounts through SMS or email