Optimized cavity and blade spacing prevent over-crushing, maintaining particle integrity and high-quality recycled output. Anti-winding comb teeth eliminate jams, even with labels or fabrics, ensuring smooth operation with minimal downtime.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

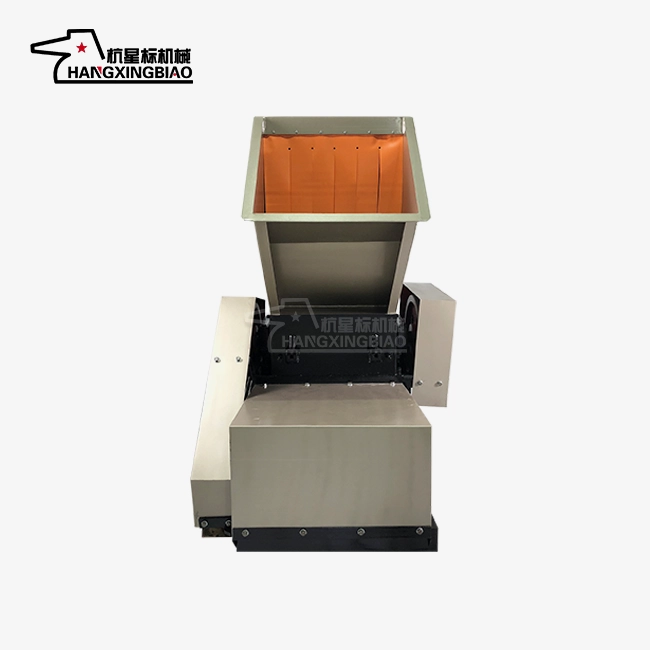

PVC pipe crusher

PVC Pipe Crusher - High-Performance Plastic Crushing Solutions for Industrial Recycling

Are you struggling with efficiently processing PVC pipe waste in your manufacturing facility? Our professional PVC pipe crusher delivers exceptional crushing performance for all types of plastic pipes, profiles, and rigid materials. Planned particularly for mechanical reusing applications, this heavy-duty machine changes squander PVC channels into uniform, reusable particles. With over 30 a long time of specialized involvement in plastic pulverizing innovation, we get it your generation challenges and convey solid arrangements that maximize fabric recuperation whereas minimizing operational costs.

Why Choose Our Heavy-Duty Pipe Crushing Equipment?

Superior Material Compatibility and Processing Power

Our crushers handle thin PVC to thick industrial pipes efficiently. The “shear + impact” process ensures over 90% uniformity, maintaining consistent particle size and eliminating the need for secondary screening, saving production time.

Exceptional Blade Technology and Durability

High-performance SKD-11 and Cr12MoV blades, treated with vacuum heat and cryogenic processes, reach HRC55–60 and last over 3,000 hours. They can be sharpened 3–5 times, reducing replacement costs by 60% and lowering maintenance expenses.

Intelligent Design Features for Maximum Efficiency

Flexible Configuration Options for Every Application

Processing Capacity Range

Our equipment lineup covers diverse production requirements:

- Small-scale operations: 50-500kg per hour capacity

- Industrial applications: 1-10 tons per hour processing power

- Continuous 24-hour operation capability

You can select the perfect model based on your specific volume requirements. Each machine delivers consistent performance across extended operating periods.

Customizable Output Specifications

Interchangeable screening meshes provide particle size flexibility from 2-100mm. Whether you need coarse fragments for pretreatment or fine particles for injection molding recycling, the PVC pipe crusher adapts to your requirements.

Quick-change screen design minimizes changeover time. You can switch between different output specifications rapidly, maintaining production efficiency across varied material processing needs.

Energy-Efficient and Cost-Effective Operation

Optimized Power Consumption

Advanced motor technology and transmission design reduce energy usage by 10-15% compared to conventional crushing equipment. Processing one ton of material requires only 8-12 kWh of electricity. Your operational costs remain controllable while maintaining high throughput.

Immediate Material Recovery Benefits

Crushed pipe materials integrate seamlessly with virgin plastics at ratios up to 50%. This material recovery capability can save tens of thousands in raw material procurement annually. Your production costs decrease while supporting sustainable manufacturing practices.

Safety and Maintenance Excellence

Comprehensive Protection Systems

Fully enclosed crushing chambers use heavy-duty steel plate construction. Anti-rebound baffles at feed openings prevent material ejection. External safety shields protect operators during normal operation.

Automatic power cutoff engages when access doors open. This "open and stop" interlock system prevents accidental contact with moving components. Your workplace safety standards exceed industry requirements.

Simplified Maintenance Procedures

Quick-access depth boards permit quick cleaning between fabric changes, anticipating color defilement. Uncovered support focuses empower assessment and grease without full dismantling, whereas accuracy orientation and solidified transmissions decrease wear and amplify component life, making upkeep more unsurprising.

Professional Support and Service Excellence

Our engineers provide full support from selection to installation and training, responding within 24 hours. Spare parts inventory enables rapid replacement, and regular follow-ups optimize performance and prevent production issues.

Get Started with Your Crushing Solution Today

Ready to transform your PVC waste into valuable recycled material? Our PVC pipe crusher technology delivers the performance and reliability your operation demands. Contact our specialists at postmaster@xingbiaocrusher.com for detailed specifications and application recommendations. Let us help you develop the perfect crushing solution for your specific requirements.

Learn about our latest products and discounts through SMS or email