Our SKD-11/D2 blades receive vacuum heat and cryogenic treatment for exceptional hardness and long life. Each unit reflects precision engineering, with a 20-engineer R&D team continually improving designs to ensure consistent, reliable performance year after year.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

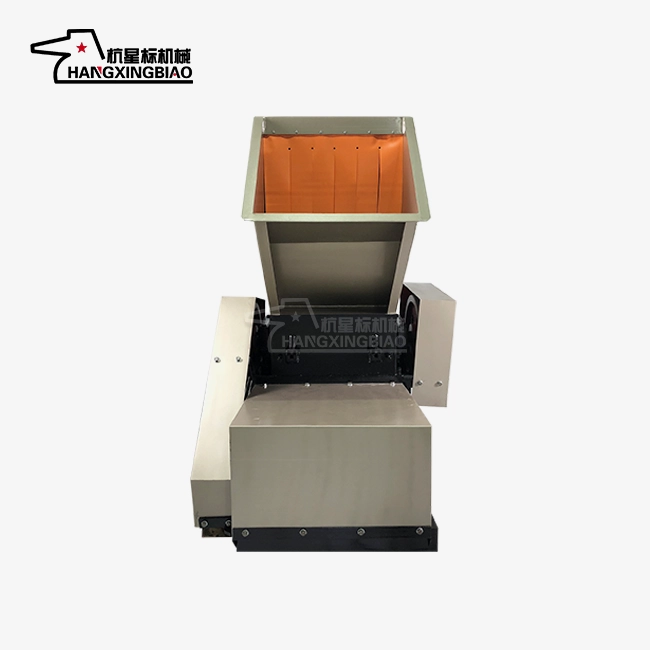

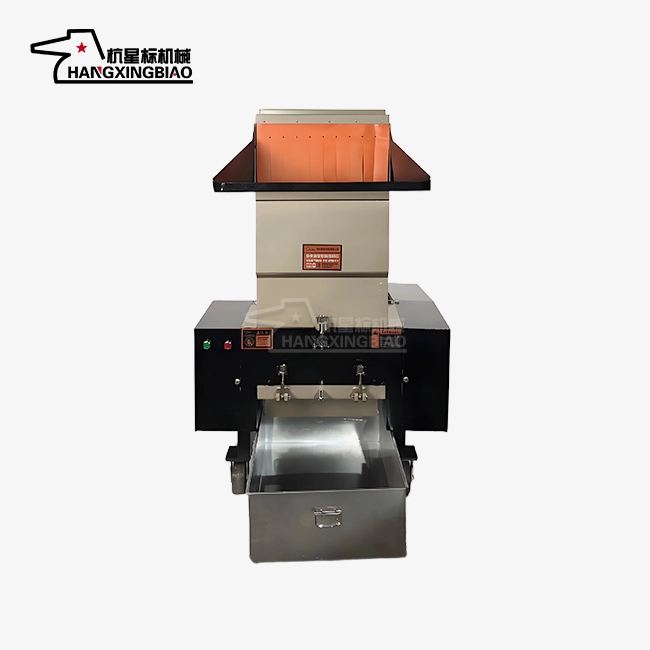

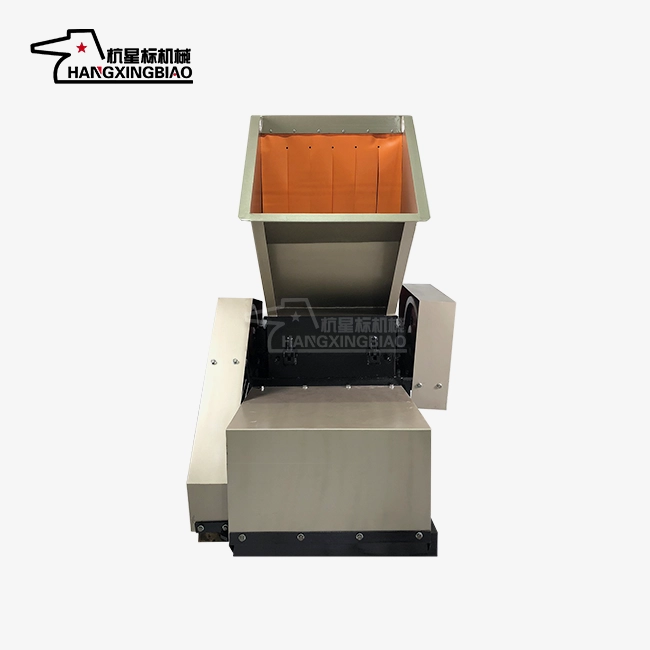

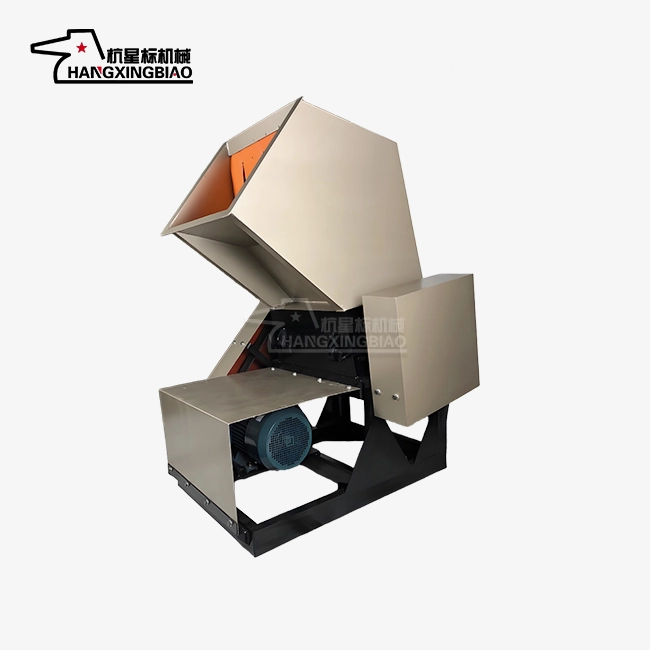

Hard plastic crusher

Heavy-Duty Hard Plastic Crusher for Efficient Plastic Waste Processing

Are you struggling with processing tough plastic waste materials? Our hard plastic crusher delivers exceptional performance for recycling centers, manufacturing plants, and industrial facilities. This robust machine efficiently processes ABS, PC, thick-walled pipes, and rigid plastic components with ease. With 30 years of specialized manufacturing experience, we understand your crushing challenges and provide reliable solutions.

Superior Engineering for Maximum Durability

Our machines feature heavy-duty construction that stands up to continuous operation. The main body uses high-strength steel plates with stress relief treatment. This prevents deformation during long-term use.

Wide Material Compatibility

This versatile equipment handles various plastic types without frequent adjustments. Whether you're processing:

- Rigid plastic parts and components

- Thick-walled pipes and profiles

- Plastic bottles and containers

- Manufacturing waste and rejects

- Mixed plastic streams

The intelligent design accommodates different material characteristics. You won't need multiple machines for different applications.

Precise Size Control

Control your output size exactly with interchangeable screens ranging from 2mm to 100mm. This flexibility allows you to:

- Produce coarse fragments (5-50mm) for pretreatment

- Generate medium particles (2-12mm) for granulation

- Achieve 90%+ particle uniformity

Simply swap screens to change your output specifications. No complex adjustments or downtime required.

Outstanding Processing Efficiency

Your productivity increases with our optimized blade layout and chamber design. Processing efficiency improves by 15-20% compared to traditional equipment.

Small models handle 50-500kg per hour, while industrial units process 1-10 tons hourly. The hard plastic crusher supports continuous 24-hour operation without material buildup or blockages.

Enhanced motor matching reduces energy consumption by 10-15%. You'll process one ton of plastic using just 8-12 kilowatt hours.

Cost-Effective Operation

Smart engineering lowers operating costs. Alloy steel tools with HRC55–60 deliver 3,000–5,000 hours of life and allow 3–5 regrinds, cutting tool expenses by 60%. Immediate recycling lets you mix 30–50% scrap with new material, saving significant annual costs.

Enhanced Safety Features

Your operators work safely with comprehensive protection systems. The crushing chamber features thick steel plate construction and anti-rebound baffles. External safety shields prevent material splash during operation.

Selected models include interlock systems that automatically cut power when chambers open. This prevents accidental injury during maintenance or cleaning.

Easy Maintenance Design

Quick-release panels speed cleaning, accessible service points cut maintenance 50%, and precision bearings with automatic lubrication ensure smooth, low-wear operation.

Flexible Model Options

Choose from mobile, fixed, or integrated configurations based on your needs:

Mobile Units: Compact designs with universal wheels for flexible positioning

Fixed Models: Floor-mounted units perfect for permanent production lines

Integrated Systems: Large-capacity units that connect with conveyors and granulators

Processing capacities range from 50kg/hour laboratory models to 10-ton industrial systems.

Quality Assurance

Every component is rigorously tested. Dynamic balance keeps vibration under 0.1 mm, reducing failures by 40%. Strict quality control ensures consistent performance, delivering equipment ready for immediate production use.

Professional Support Services

We provide comprehensive support throughout your equipment lifecycle. Our team responds to inquiries within 24 hours. Installation guidance and operator training ensure optimal performance from day one.

Regular follow-up visits and sufficient spare parts inventory minimize any potential downtime. Professional engineers assist with application selection and process optimization.

Start Improving Your Plastic Processing Today

Transform your plastic waste processing with proven hard plastic crusher technology. Contact our applications team at postmaster@xingbiaocrusher.com for personalized recommendations. We'll help you select the perfect configuration for your specific requirements and processing goals.

Learn about our latest products and discounts through SMS or email