Our crushers use stress-relieved high-strength steel and SKD-11/D2/Cr12MoV blades treated with vacuum and cryogenic processes, ensuring long-term stability and maximum durability.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

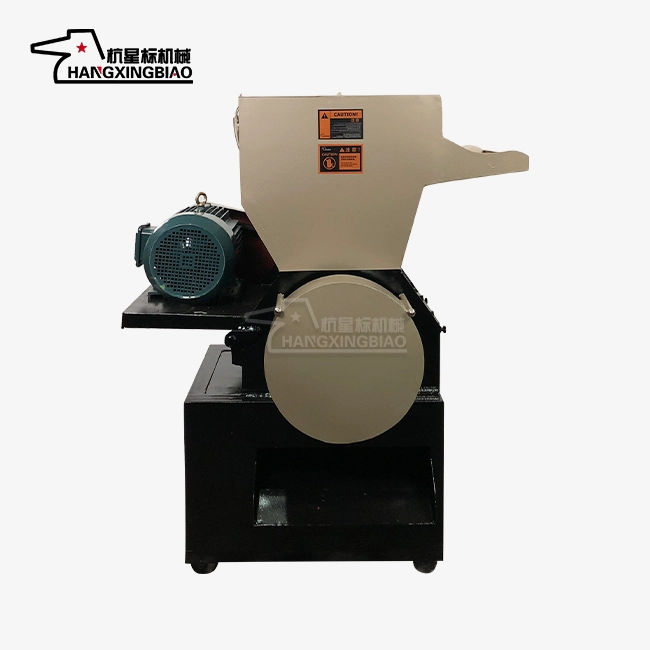

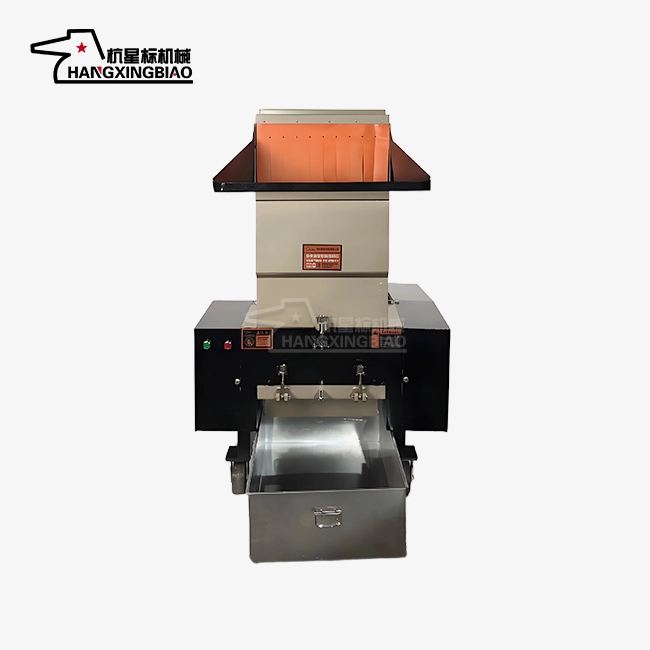

Glass crusher

Glass Crusher: Professional Glass Recycling Equipment for Your Business

Are you looking for an efficient solution to process waste glass materials? Our glass crusher delivers exceptional performance for glass recycling operations, helping you transform glass waste into valuable resources. Whether you're managing with bottles, holders, or mechanical glass squander, this flexible machine offers the culminate combination of control, proficiency, and unwavering quality. You'll find how this progressed smashing innovation can altogether diminish your squander transfer costs whereas making modern income streams from reused glass materials.

Why Choose Our Glass Crushing Equipment?

Proven Expertise and Experience

With 30 years’ crushing equipment expertise, our 20 senior engineers leverage major-industry partnerships to deliver top-quality, high-performance machines.

Superior Build Quality

Enhanced Efficiency and Energy Savings

Optimized blade layout and cavity boost efficiency 20%, while matched motors cut energy use, enabling higher throughput with lower electricity costs.

Key Features and Benefits

Wide Material Compatibility

This machine efficiently processes diverse glass types—from bottles to industrial waste—handling mixed colors and automotive glass consistently without frequent adjustments.

Precise Particle Size Control

Achieve accurate and controllable output sizes in the glass crusher by changing screening nets with different pore sizes. Options range from 2–100 mm depending on your specific requirements. The particle uniformity exceeds 90%, eliminating the need for secondary screening processes.

High Processing Capacity

Our equipment scales from 50 kg–10 t/hour, supporting flexible processing for small recycling centers to large industrial facilities.

Durable Cutting Tools

The cutting system’s HRC55-60 alloy tools last 3000–5000 hours, support repeated sharpening, and cut replacement costs 60% versus standard carbon steel.

Advanced Safety Features

Safety is prioritized with thick steel chambers, anti-rebound baffles, external shields, and interlocking devices that cut power when accessing the crushing chamber.

Operational Advantages

Low Energy Consumption

Efficient motors and optimized transmission cut energy use 10–15%, needing only 8–12 kWh per ton, delivering significant long-term cost savings.

Minimal Maintenance Requirements

The transmission uses precision bearings, hardened gears, and dynamic balance testing, reducing vibration, lowering failures 40%, and cutting maintenance time by 50% with easy access.

Easy Cleaning and Operation

The simple body design of the glass crusher allows quick disassembly of cavity sides for thorough cleaning. This feature is especially valuable when switching between different glass types. Key maintenance points remain exposed for daily inspection without full machine disassembly.

Flexible Model Options

Choose from three main configurations to match your specific needs:

Mobile Units: Small, portable designs with universal wheels for flexible positioning across different work stations.

Fixed Installation: Medium-sized floor-mounted units perfect for established production lines.

Integrated Systems: Large-scale equipment that links with conveyors and other processing equipment for automated production lines.

Our range covers everything from laboratory testing requirements (50kg/h) to large-scale recycling operations (10t/h).

Applications Across Industries

Glass Bottle Recycling

Transform waste beverage bottles, wine bottles, and food containers into clean glass cullet for new bottle manufacturing.

Construction Industry

Process architectural glass waste into aggregate for concrete applications or decorative landscaping materials.

Industrial Glass Processing

Handle manufacturing waste from glass production facilities, converting scrap into reusable raw materials.

Municipal Waste Management

Support community recycling programs by efficiently processing collected glass waste into marketable materials.

Technical Support and Service

We offer full lifecycle support with expert selection advice, customized solutions, 24-hour response, installation guidance, training, follow-ups, and readily available spare parts to minimize downtime and optimize crushing operations for maximum ROI.

Get Started Today

Ready to transform your glass waste management approach? Our glass crusher technology offers the reliability, efficiency, and performance your operation demands. Contact our technical team at postmaster@xingbiaocrusher.com to discuss your specific requirements and discover the perfect solution for your glass processing needs.

Learn about our latest products and discounts through SMS or email