Our crushing systems, built from stress-relieved high-strength steel, provide long-term dimensional stability. Premium SKD-11 and D2 cutting blades, treated with vacuum heat and cryogenic processes, achieve HRC 55–60 hardness and a service life exceeding 3,000 hours, ensuring reliable performance in demanding industrial environments.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

garbage crusher

Industrial Garbage Crusher: High-Performance Waste Reduction Solutions

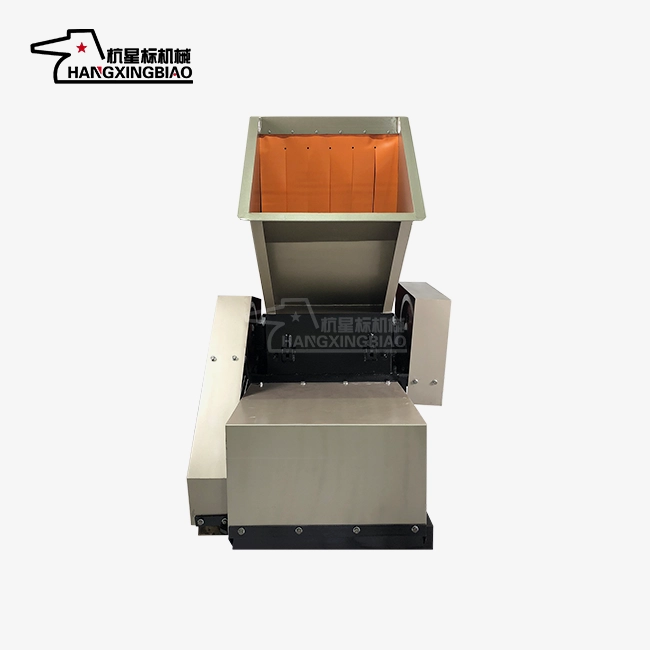

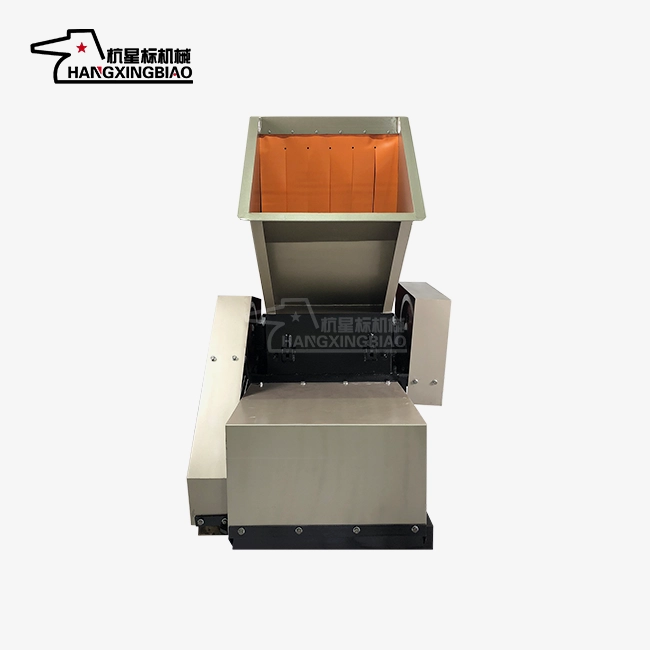

When your facility generates substantial waste volumes, you need reliable equipment that delivers consistent results. Our industrial garbage crusher combines advanced engineering with proven durability to handle your toughest waste processing challenges. This versatile machine transforms various waste materials into manageable sizes, reducing disposal costs while supporting your recycling initiatives. Built for continuous operation, the product processes everything from plastic containers to organic waste efficiently.

Professional Waste Processing Equipment

Advanced Dual-Action Technology

Your processing efficiency improves dramatically with our "shear + impact" crushing methodology. This dual-action approach optimizes material breakdown while maintaining particle integrity. You get uniform output without excessive powder generation.

Optimized cavity spacing allows 2 mm+ discharge, and anti-wrapping comb teeth prevent jamming with fibrous materials, eliminating production stoppages.

Versatile Material Handling Capabilities

Our system processes diverse wastes—soft PE/PVC films, woven bags, hard ABS/PC plastics, thick pipes, and EPS/EVA foam—efficiently without equipment changes.

Processing capacity scales from 50-500kg/hour for smaller units up to 1-10 tons/hour for industrial models. Continuous 24-hour operation capability ensures you meet demanding production schedules. Efficiency gains of 15-20% over traditional equipment reduce processing bottlenecks.

Precise Output Control

Interchangeable screens (2–100 mm) allow precise particle control: coarse (5–50 mm) for pretreatment, medium (2–12 mm) for granulation or injection molding. Over 90% uniform output, with variable speeds and blade options, provides flexible production without equipment changes.

Cost-Effective Operation

Your operating expenses stay controlled through intelligent design features in the garbage crusher. Energy consumption reduces 10–15% compared to conventional equipment. Processing one ton of material typically requires just 8–12 kWh.

Blade durability minimizes replacement costs. Our alloy cutting tools support repeated sharpening cycles (3-5 times). This extends useful life while reducing replacement expenses by 60% versus standard carbon steel alternatives.

Safety and Reliability Features

Your team operates in a protected environment with comprehensive safety systems. Fully enclosed crushing chambers use thick steel plate construction. Feed openings include anti-rebound shields to contain material discharge.

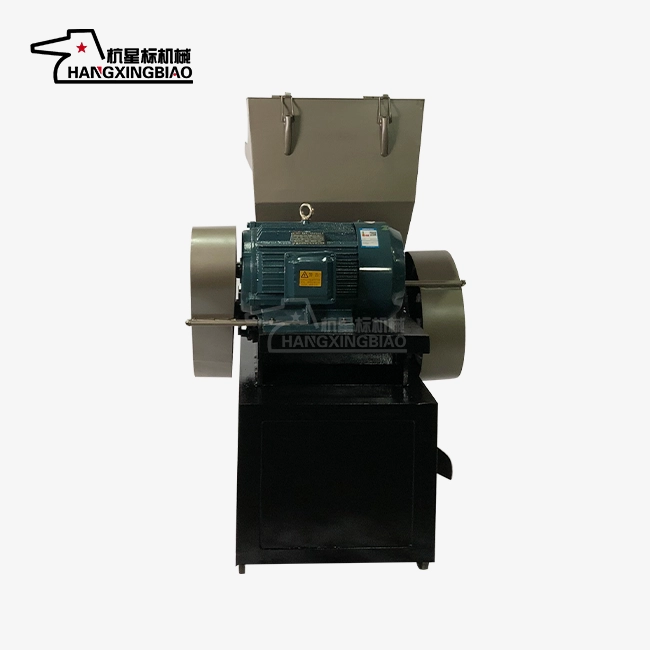

External guards prevent debris projection, and interlocks cut power when chambers open for safe maintenance. Precision bearings, hardened transmission, and dynamic balancing reduce vibration ≤0.1 mm, lowering fatigue and failure rates 40% with regular lubrication.

Flexible Configuration Options

Your facility layout determines the optimal machine configuration. Mobile units with universal wheels move easily between work stations. Fixed installations anchor securely to production floors. Integrated systems connect with conveyors and granulators for automated processing lines.

Laboratory-scale units handle 50kg/hour for testing applications. Large recycling facilities benefit from 10-ton/hour industrial models. Custom configurations address unique processing requirements.

Simple Maintenance Design

Your maintenance schedule stays manageable with user-friendly design features. Side panels remove quickly for chamber cleaning. This prevents color contamination when switching between different plastic types.

Accessible maintenance points allow inspection and lubrication without complete disassembly. Maintenance time reduces by 50% compared to complex designs. Quick-change screen structures minimize downtime during size adjustments.

Contact Us

Ready to improve your waste processing efficiency with a garbage crusher? Contact our engineering team at postmaster@xingbiaocrusher.com for personalized consultation and system recommendations tailored to your specific requirements.

Learn about our latest products and discounts through SMS or email